Flexible spray gun for treating or inspecting tube bottoms of steam generators

A steam generator and flexible technology, applied in steam generation, steam boiler components, steam boilers, etc., can solve the problems of high price, small manufacturing tolerance, high accuracy, etc., to save materials, improve flexibility, and avoid bending Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

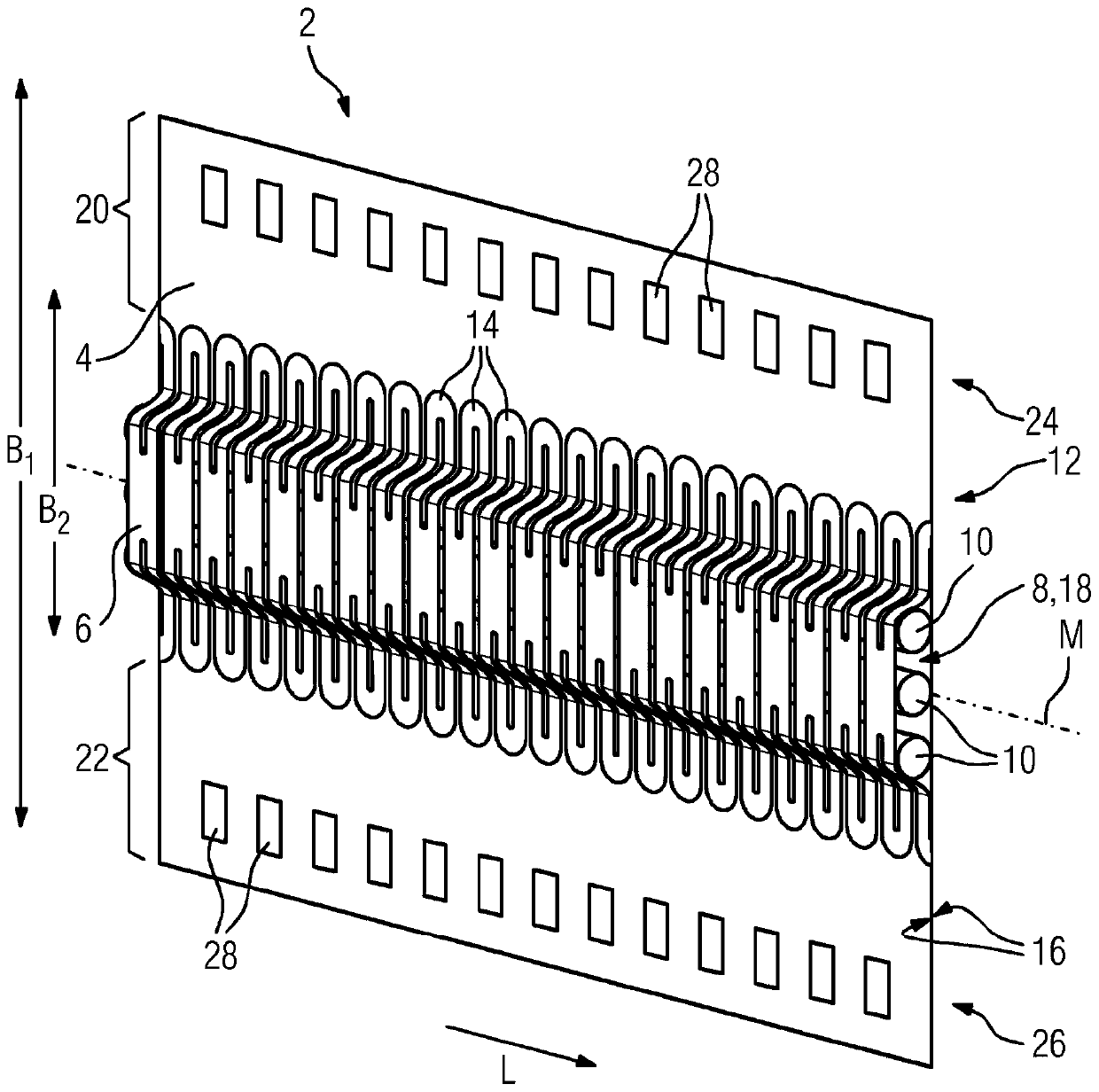

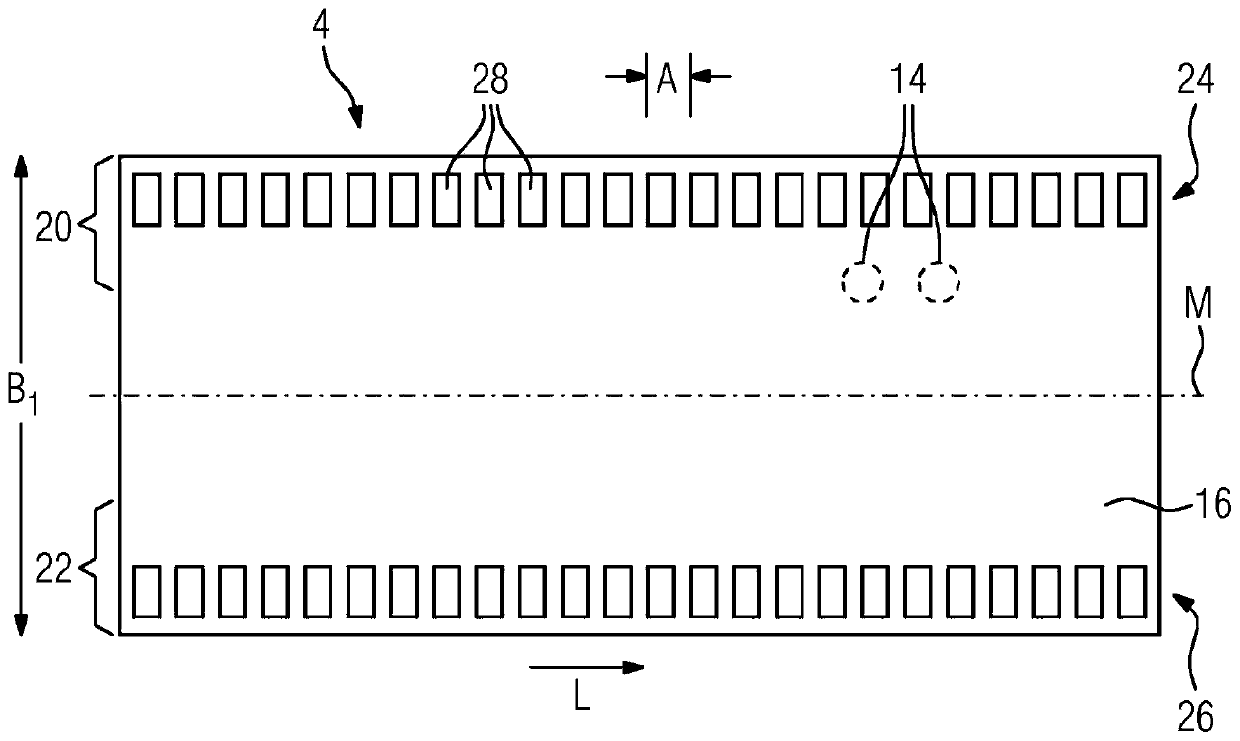

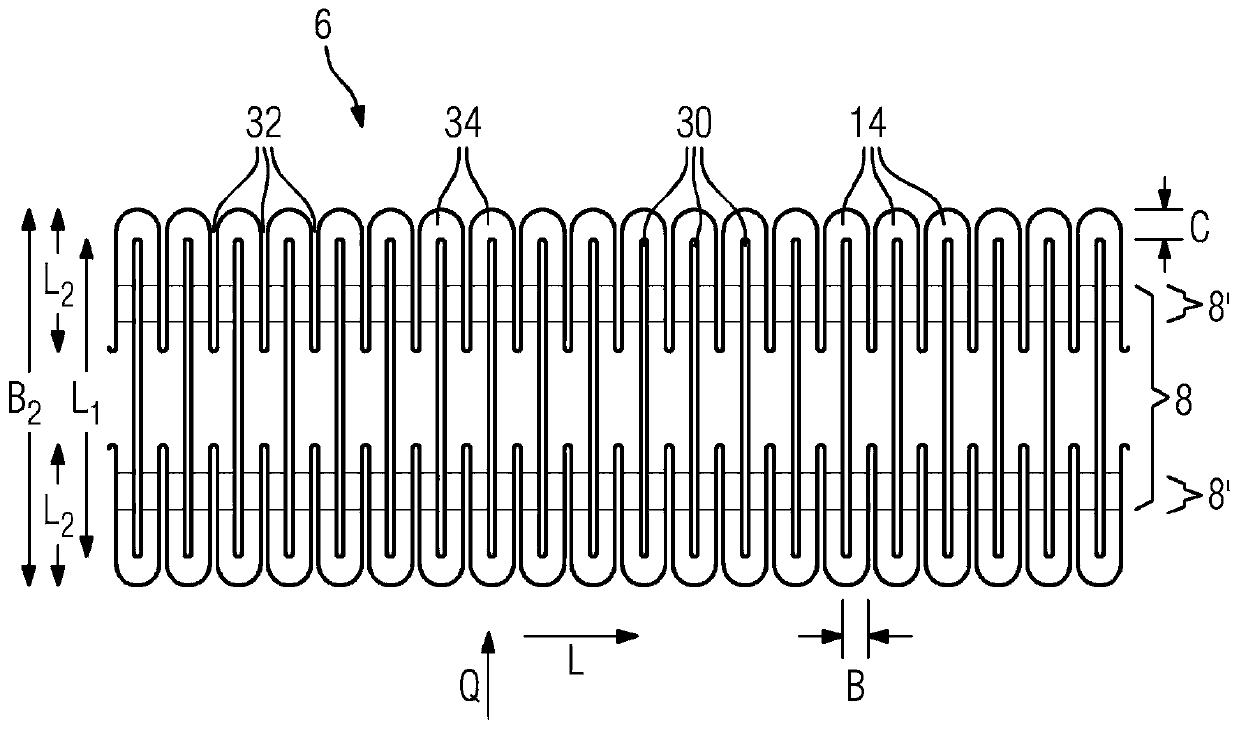

[0025] figure 1 A flexible lance 2 for treating or inspecting the tube bottom of a steam generator is shown. The flexible spray gun 2 consists of a flexible metallic first strip 4 and a flexible metallic second strip 6 . The two strips 4 , 6 are made of spring steel, for example chrome-nickel steel, and have a thickness or wall thickness of approximately 0.1 to 0.3 mm. Width B of the first belt 4 1 About 40mm, the width B of the second belt 6 2 About 24mm. Therefore, the second strip 6 has a smaller width than the first strip 4 . The second belt 6 is arranged on the first belt 4 in the longitudinal direction L and has a forming 8 or housing extending in the longitudinal direction L to accommodate three supply lines 10 which are connected to free lances arranged on the flexible spray gun 2 . Processing head or inspection head at end 12 (in figure 1 not shown for clarity). The profile 8 has a profile that is U-shaped in cross section and extends in the longitudinal direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com