Automatic knitting machine for metal net

A weaving machine and metal mesh technology, which is applied in the field of metal mesh automatic weaving machines, can solve problems such as difficulty in guaranteeing product quality, low production efficiency, and uneven weaving levels, and achieve the goals of saving manpower, improving product quality, and improving weaving efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

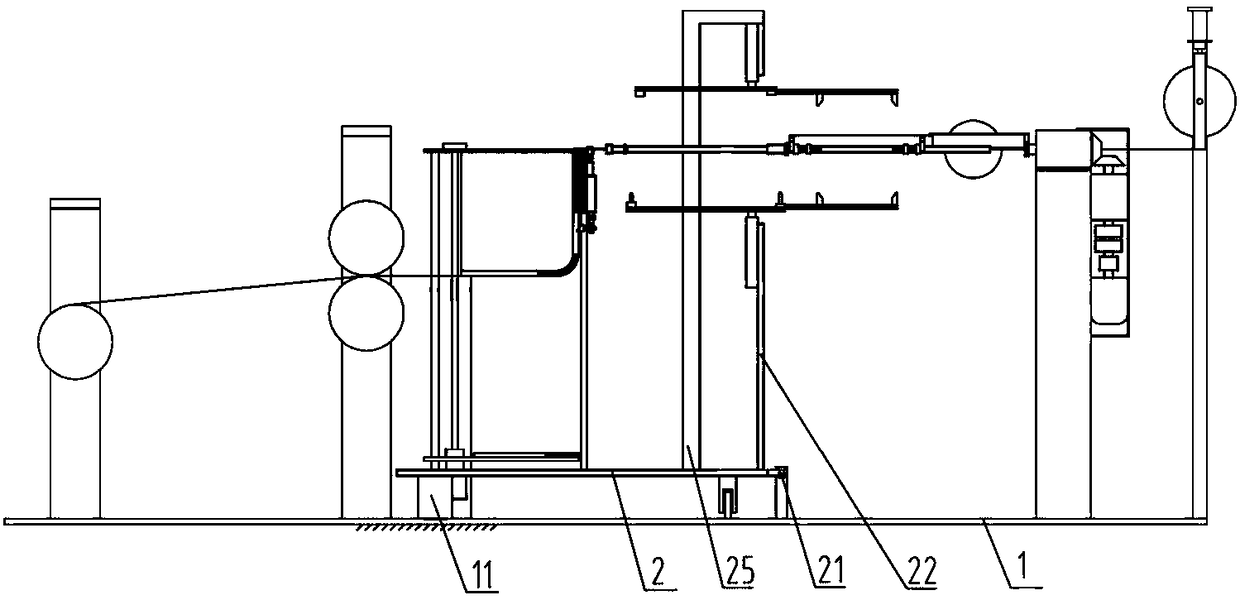

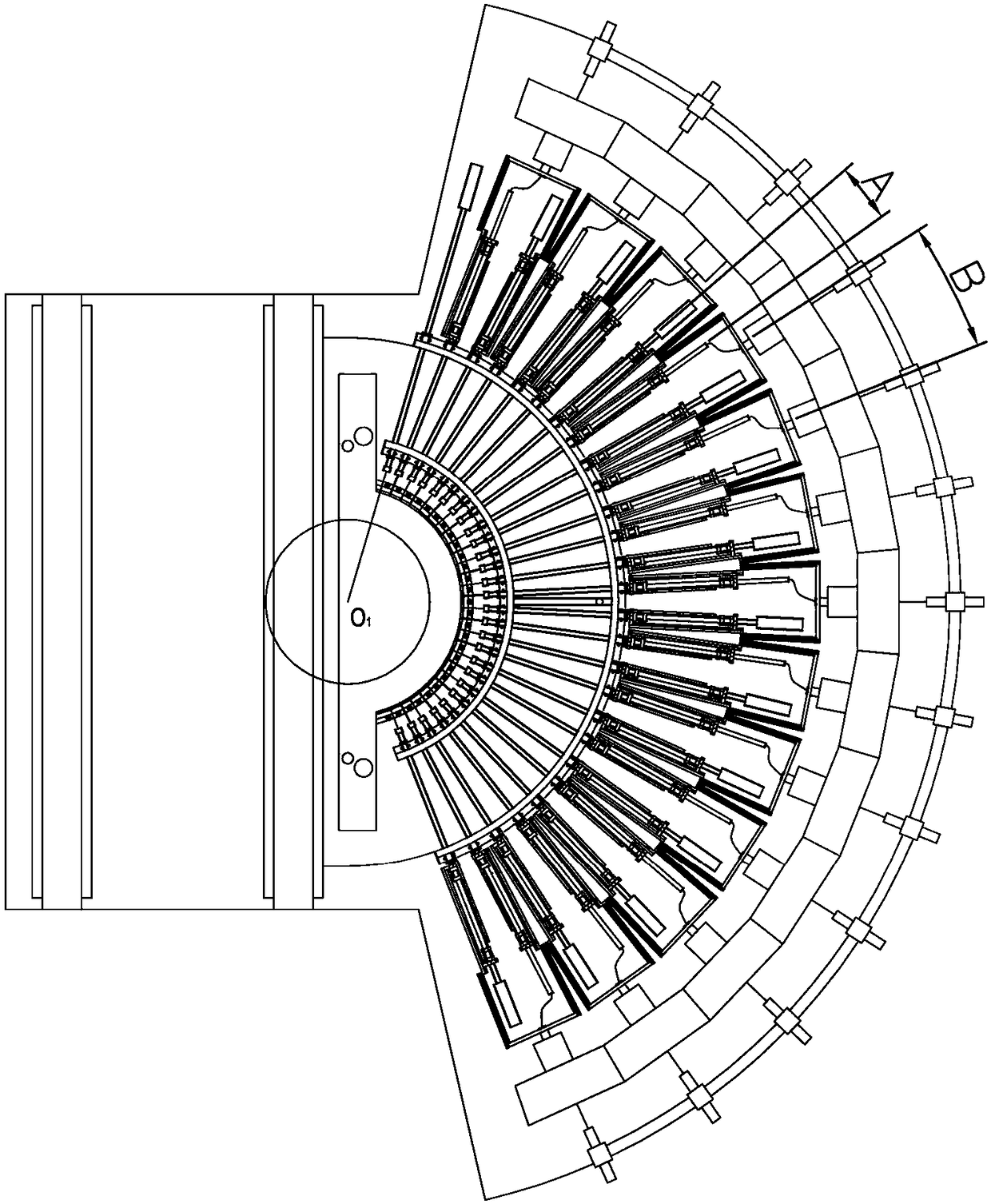

[0022] see Figure 1 to Figure 3 , The metal mesh automatic weaving machine includes a frame 1, a turntable 2, a screwing device and a power device. The frame 1 is provided with a bearing seat 11, and a bearing is arranged in the bearing seat 11. The turntable 2 is rotatably installed on the frame 1 through the bearing seat 11 and the bearing. The rotating shaft of the bearing is the rotating shaft O1 of the turntable 2. The turntable 2 is hinged to one end of the electric push rod 121, and the electric push rod 121 is driven by the hydraulic cylinder or pneumatic cylinder installed on the frame 1, and the turntable 2 can rotate around the rotation axis O1 under the push of the electric push rod 121. Do a small range of reciprocating rotation relative to the frame 1.

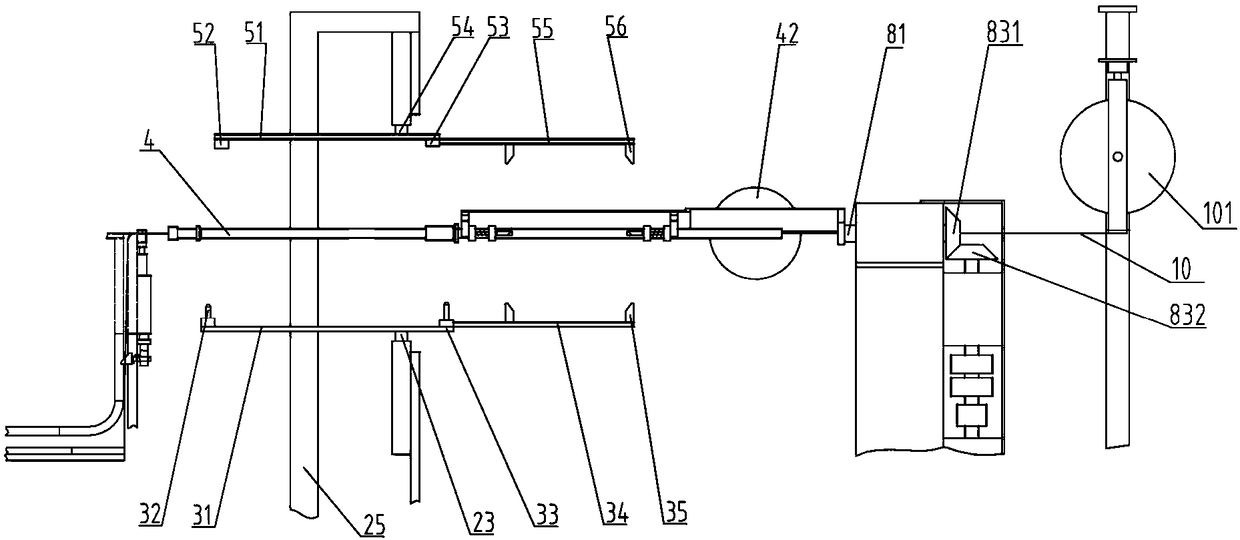

[0023] The turntable 2 is provided with a fan-shaped lifting platform, and the lifting platform rotates around the rotation axis O1 together with the turntable 2 . see image 3 with Figure 4 , the lifting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com