Automatic diode feeding device

A technology of automatic feeding and diodes, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low production efficiency and improper placement of manual operations, and avoid equipment that may cause harm to people. The effect of accurate placement and ingenious structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

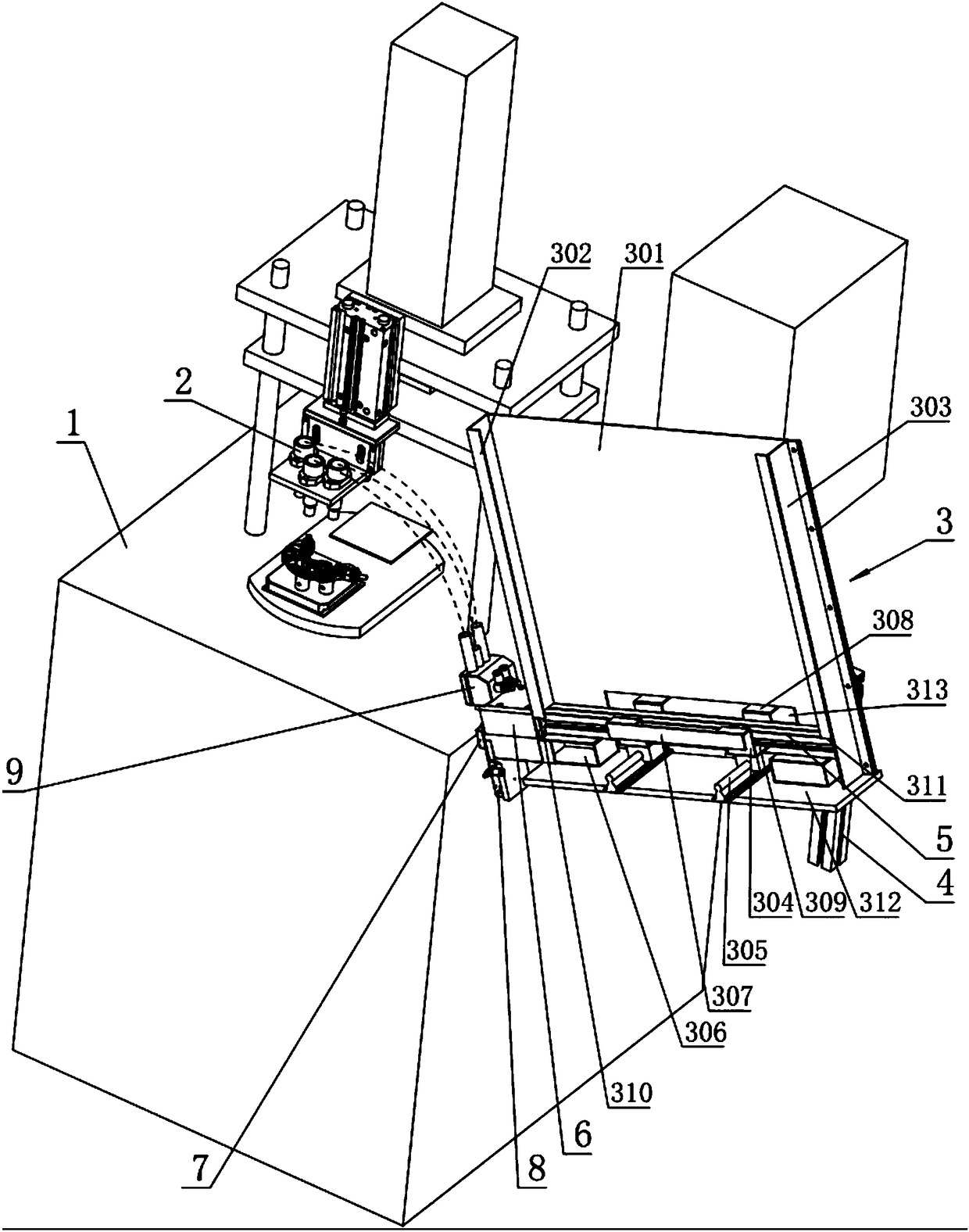

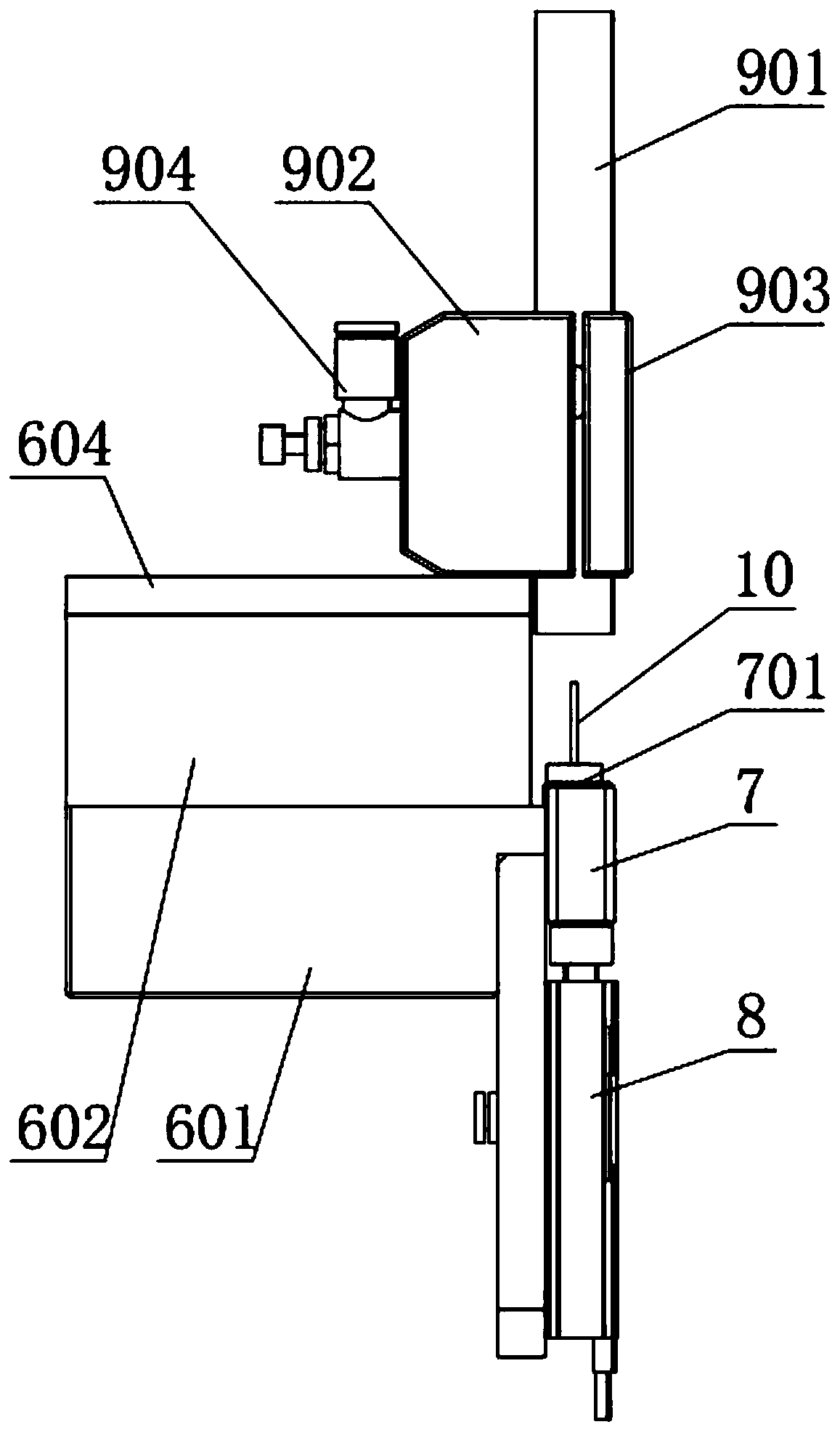

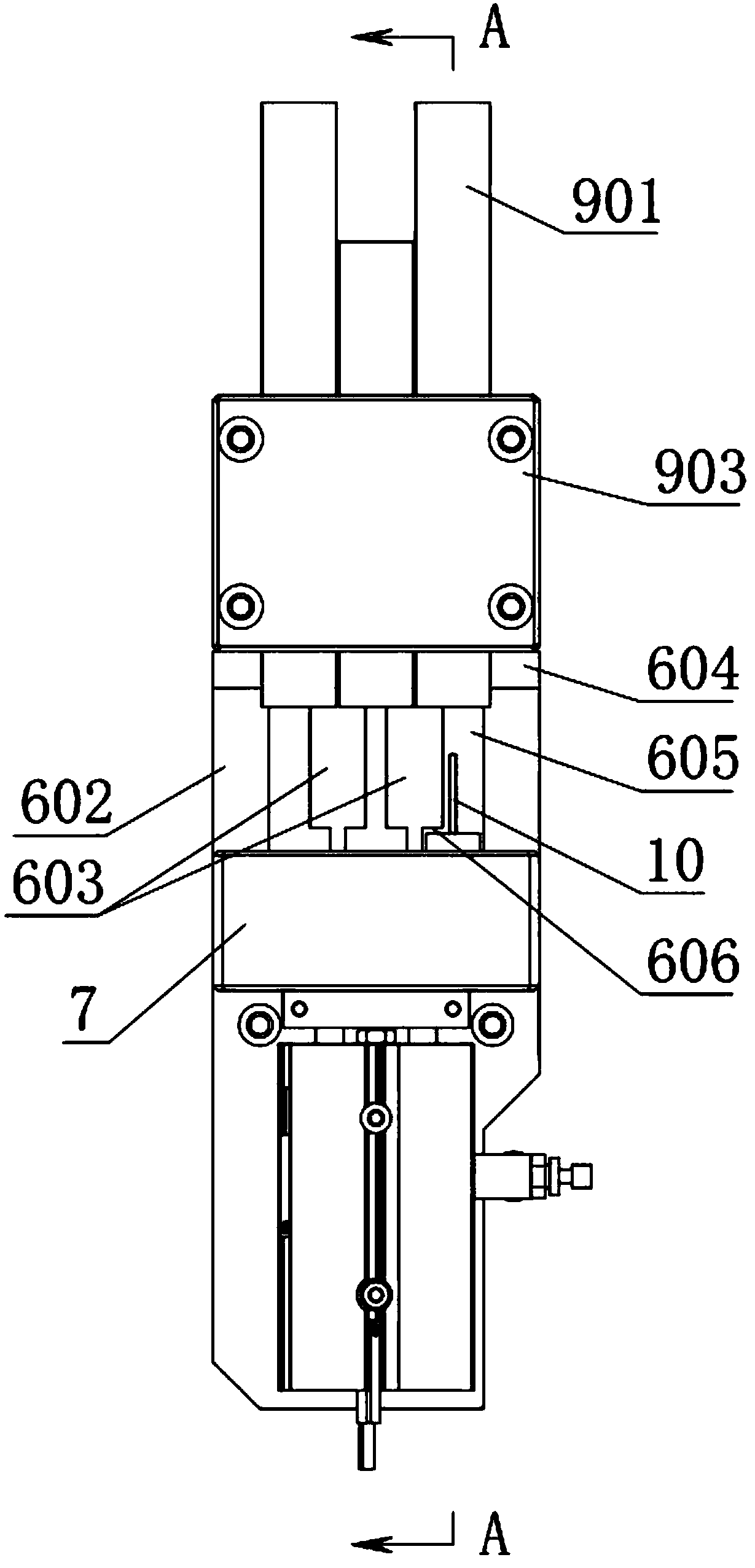

[0022] like Figure 1-Figure 4 As shown, the diode automatic feeding device includes an inclined feeding rack 3, a feeding channel 6 located at the lower end of the inclined feeding rack 3, a material receiving seat 7 located at the outlet of the feeding channel 6, and a material receiving seat 7 located at the outlet of the feeding channel 6. The lifting mechanism 8 at the bottom of the seat 7, the material suction and export mechanism 9 located at the top of the material receiving seat 7.

[0023] Described inclined feeding frame 3 is made of base plate 312, is located at the top of base plate 312 and is used for importing the box body 5 of splendid attire diode from top to bottom semi-open guide frame that is perpendicular to base plate 312, corresponding semi-open guide frame two. The support block 306 arranged on the bottom plate 312 at the inner side of the end is composed of a push-pull bracket set on the bottom plate 312 at a position between the two support blocks 306...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com