Fabrication method for die of curved plate

A production method and technology of curved panels, applied in 3D modeling, processing models, decorative arts, etc., can solve the problems of cost saving and architectural effect at the same time, difficulty in realizing free-form curtain walls, and no good solutions, etc., to achieve The effect of increasing the engraving speed, reducing the engraving cycle, and engraving resistance is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

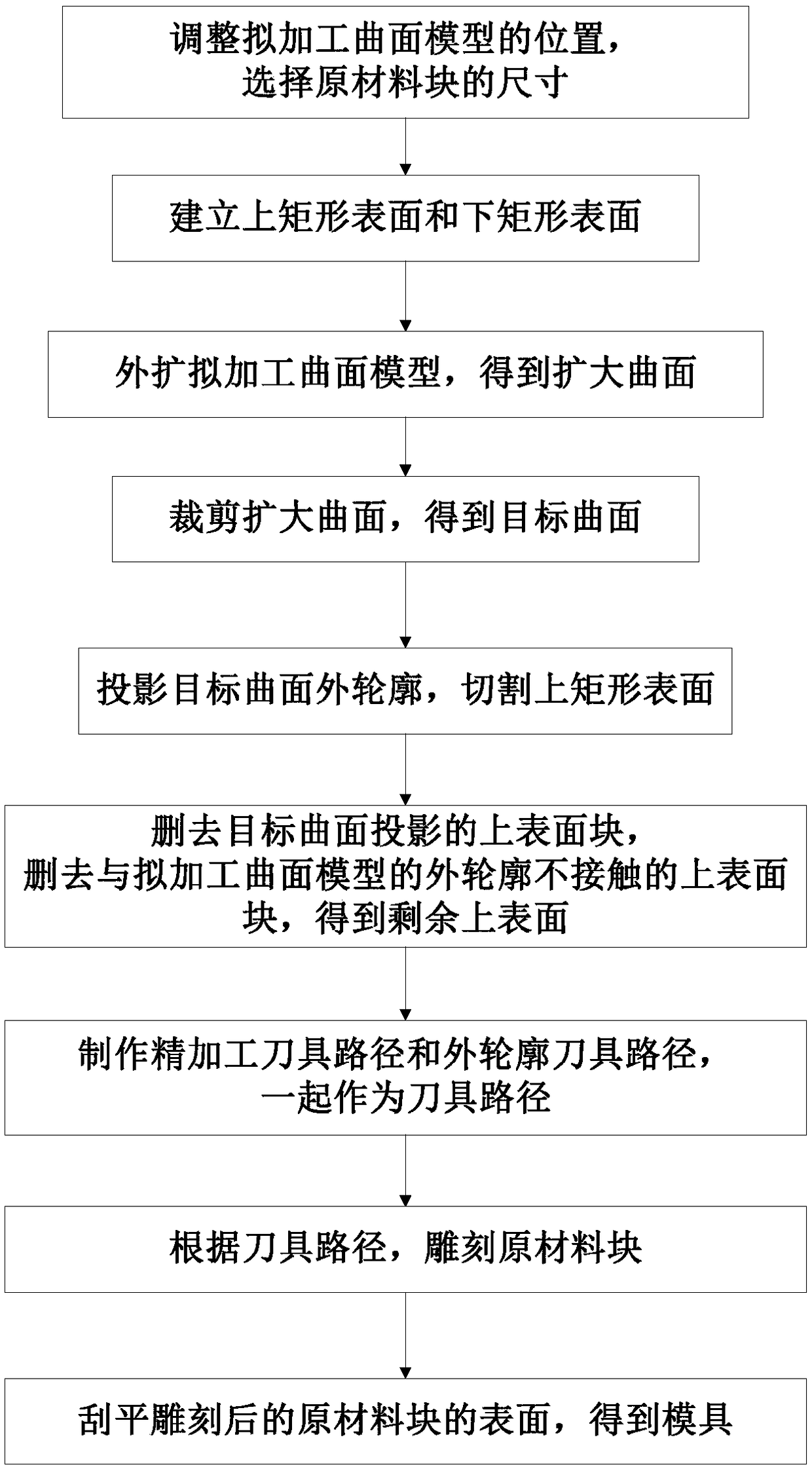

[0026] The invention proposes a manufacturing method of a mold for a curved panel, figure 1 Shown as its flow chart, in this embodiment, the curved panel is a GFRP building curtain wall free curved panel. The production method is specifically:

[0027] Firstly, select the GFRP surface model to be processed in the 3D software, and the GFRP surface model to be processed is the 3D model of the GFRP curved panel to be processed. Adjust the position of the GFRP surface model to be processed, and copy the surface outline of the GFRP surface model to be processed. Analyze the frame block of the GFRP surface model to be processed, and select the size of the mold raw material block corresponding to the modular size according to the size of the frame block. The raw material block selected in this embodiment is a cuboid, and its dimensions are: length ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com