Intelligent fast horizontal moving and turning-connection loading and unloading vehicle for container

A technology for containers and loading and unloading trucks, applied in loading/unloading, transportation and packaging, conveyors, etc., can solve the problems of cumbersome on-site management and dispatching system, high investment cost and equipment maintenance cost, and chaotic on-site dispatching, and achieve on-site management and dispatching Simple, reduce input and maintenance costs, and reduce storage costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

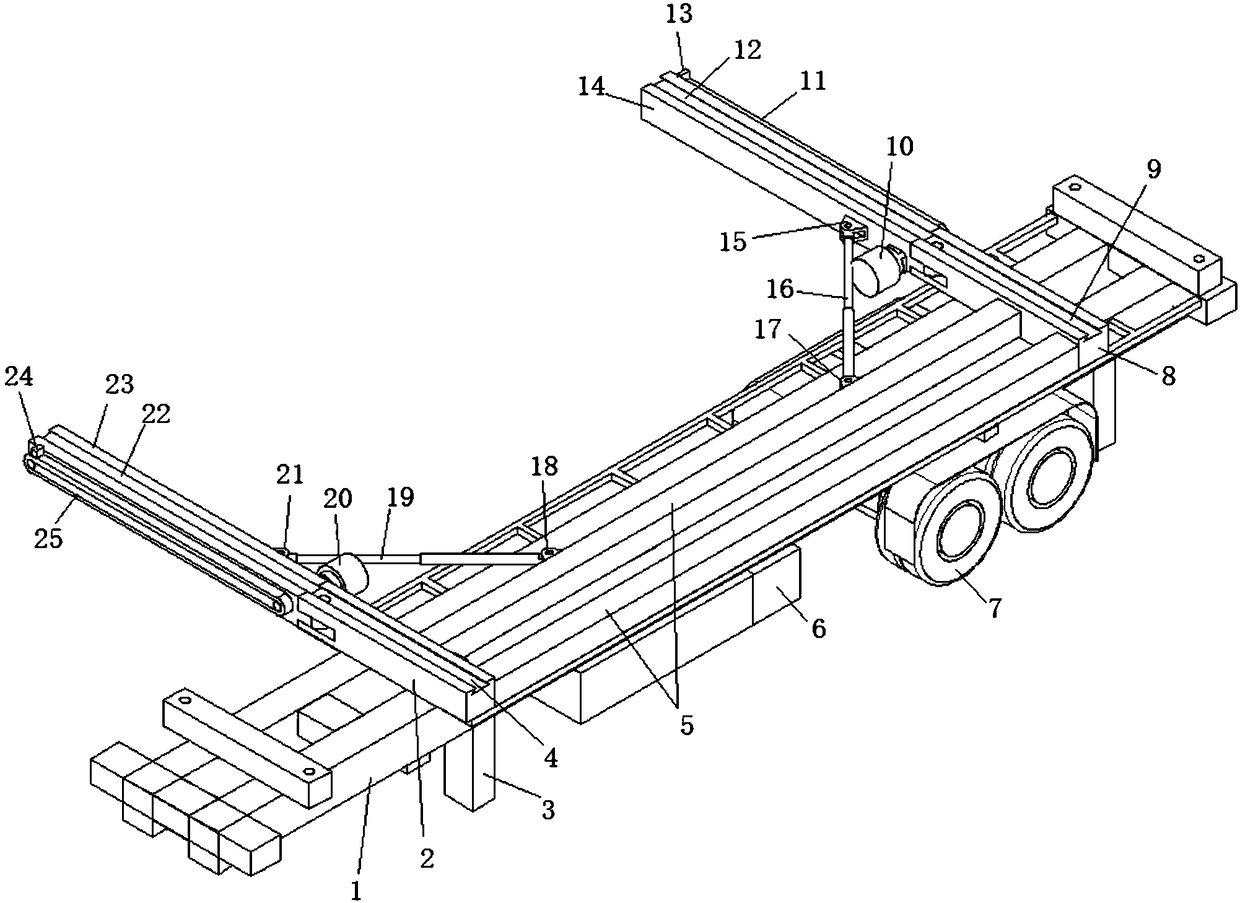

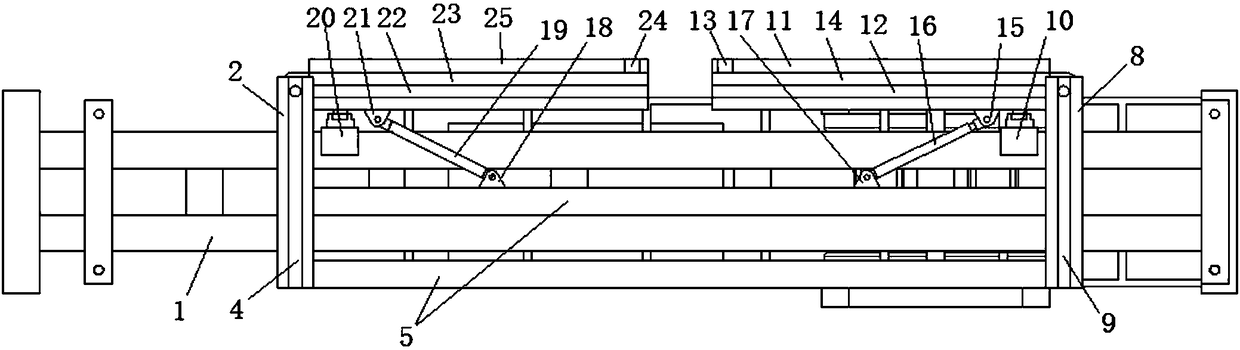

[0046] Such as figure 1 with figure 2 As shown, an intelligent container rapid translation transfer loading and unloading truck includes a body 1, a controller 6 and a translation mechanism;

[0047] A lifting device 3 for driving the lifting of the vehicle body 1 is installed on the bottom of the vehicle body 1, and a distance sensor for obtaining the height of the vehicle body 1 is installed on the vehicle body 1. The controller 6 controls the lifting by obtaining the distance signal fed back by the distance sensor. The operation of lifting device 3;

[0048] The translation mechanism includes a first fixed arm 2 and a second fixed arm 8. Both the first fixed arm 2 and the second fixed arm 8 span the top of the vehicle body 1 and are fixed to the top of the vehicle body 1. One end of the first fixed arm 2 can be horizontal The first swing arm 23 is rotatably connected, and the end of the second fixed arm 8 corresponding to the first swing is horizontally rotatably connected with...

Embodiment 2

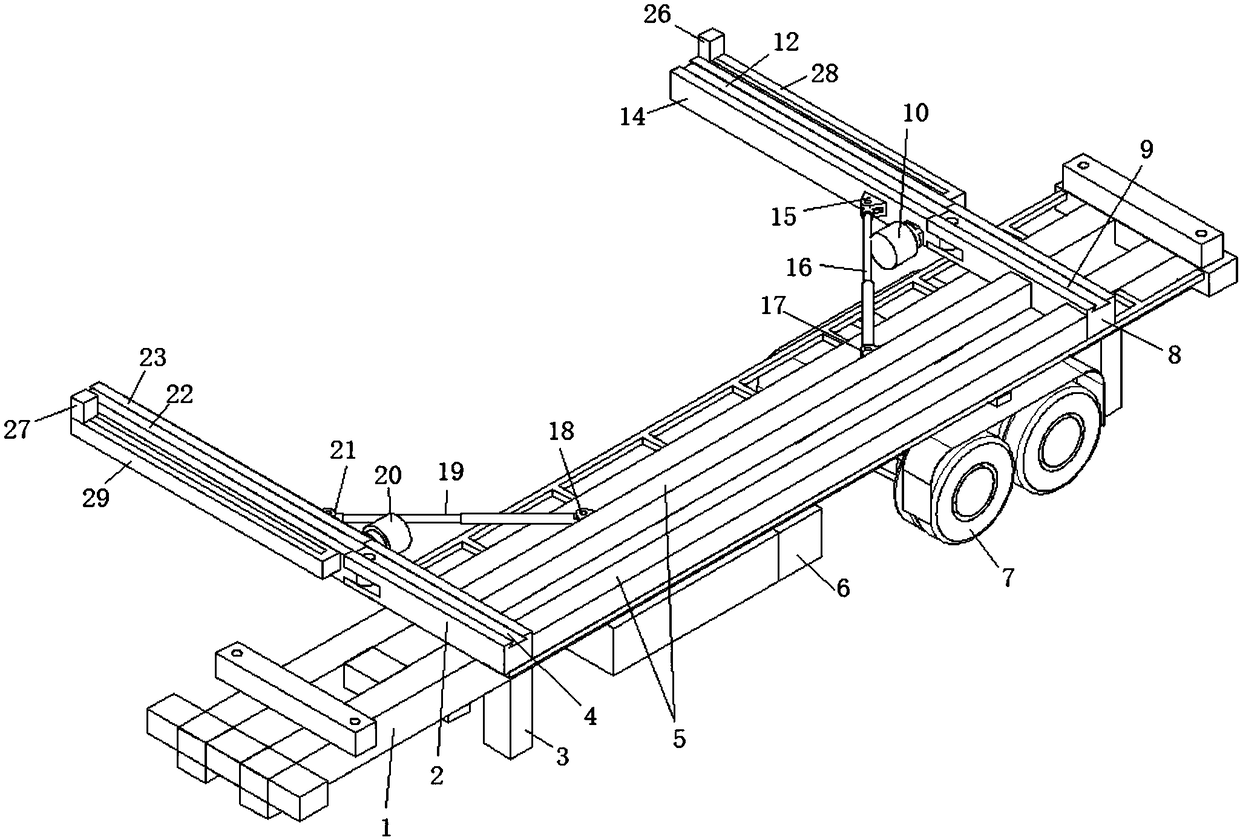

[0055] Such as image 3 with Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the first container transmission device includes a first screw 29 and a first right angle motor. The first screw 29 is installed on the first swing arm 23 away from the first telescopic device 19 and connected to the first On one side of a swing arm 23, the first right angle motor is installed on the side of the first swing arm 23 opposite to the first screw 29. The output end of the first right angle motor is connected to the screw of the first screw 29. A projection C27 is fixed on the nut of the lead screw 29; the second container transmission device includes a second lead screw 28 and a second right angle motor. The two lead screws are installed on the second swing arm 14 away from the second telescopic device 16 and connected to the second swing arm On one side of 14, the second right-angle motor is installed on the side of the second swing arm 14 opposite to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com