Ball valve core with flow rate regulating function

An adjustable, spherical valve core technology, applied in the field of ball valve core, can solve the problems of unsatisfactory steam medium adjustment effect, short service life, easy damage to the valve core, etc., to avoid high-speed medium erosion, long service life, adjustment high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

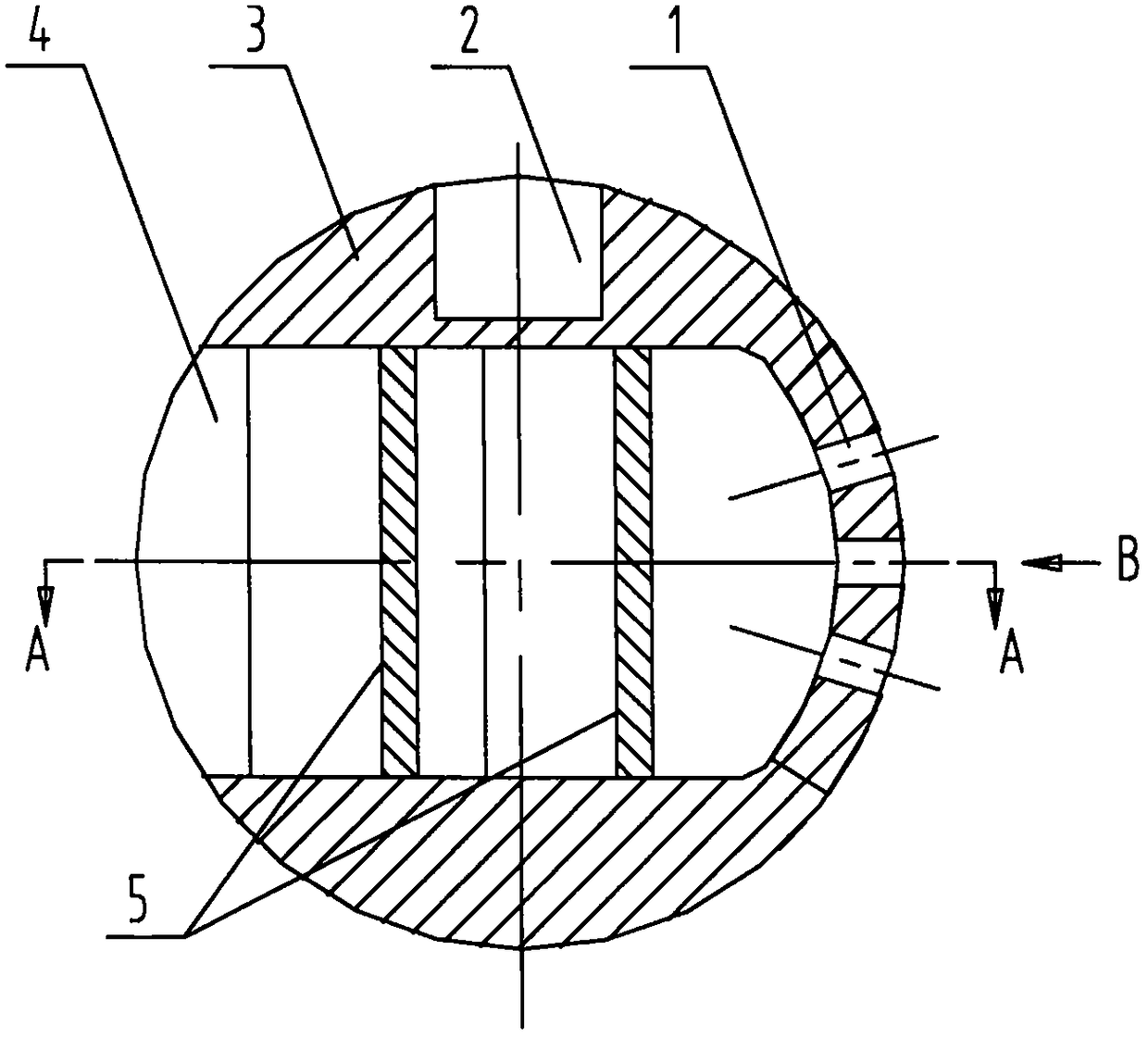

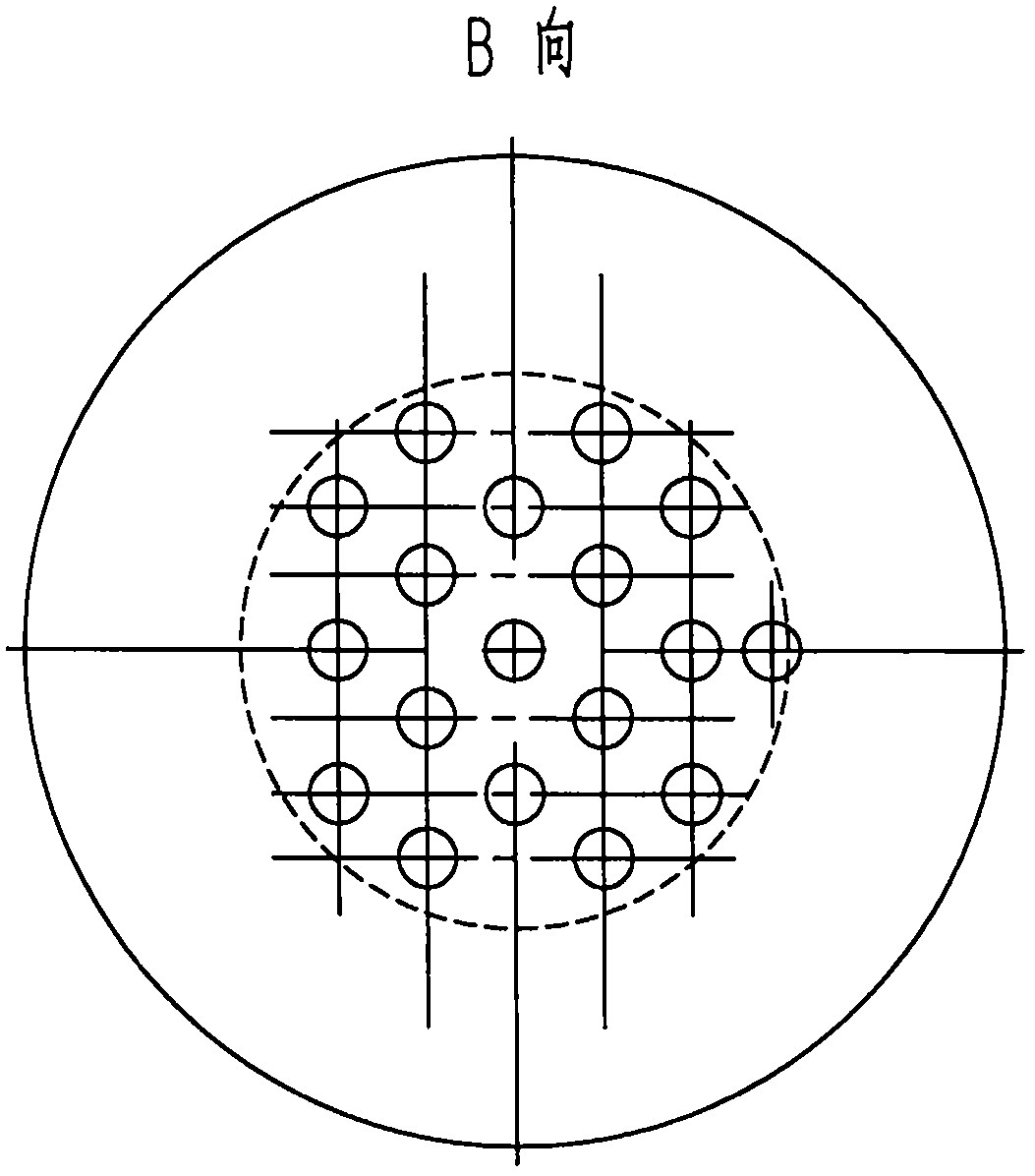

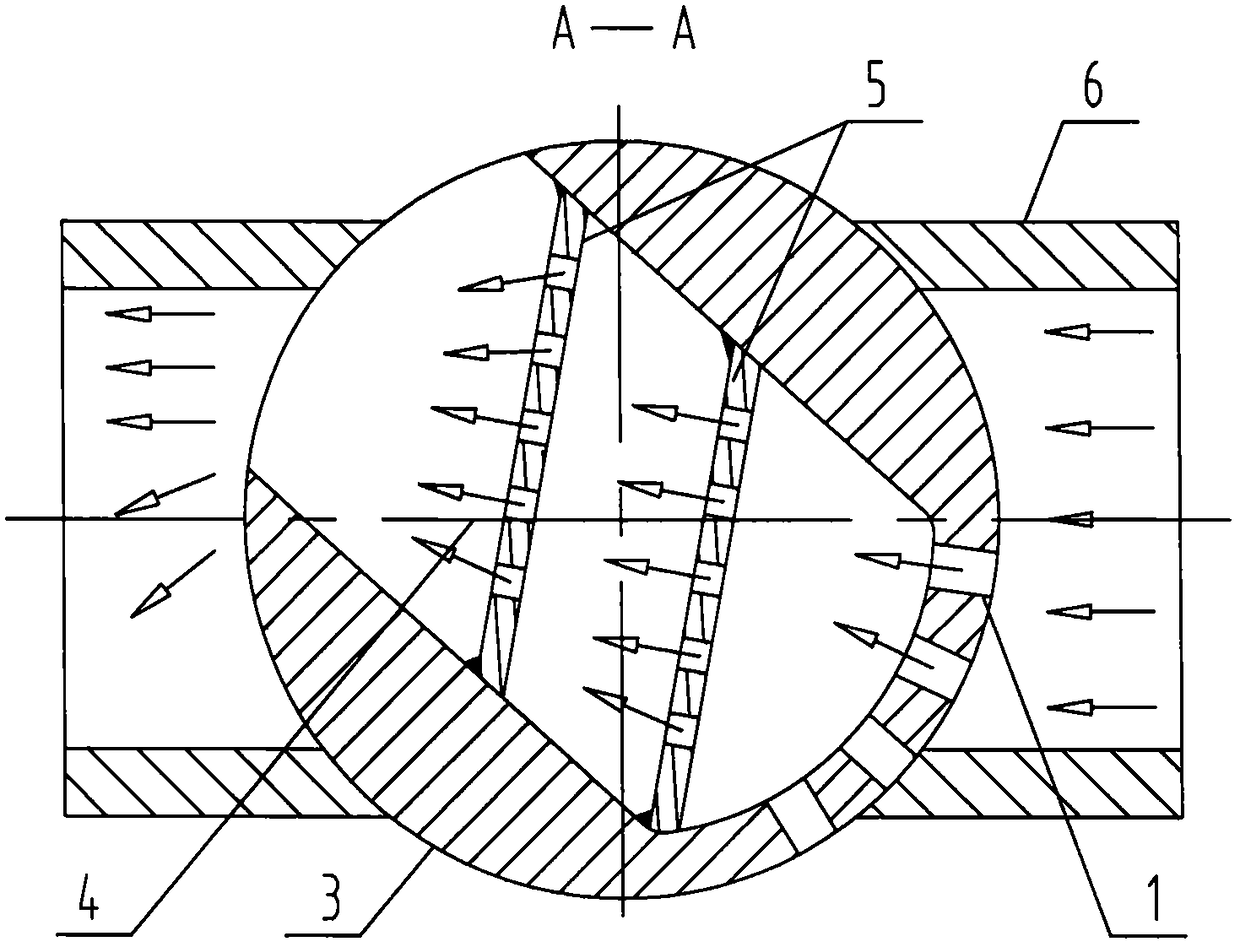

[0011] Such as figure 1 As shown, the present invention comprises a spherical valve core body 3, a spherical adjusting pair 1, a throttling orifice 5, the middle part of the spherical valve core body 3 is a medium through hole 4, and one end of the medium through hole 4 is a spherical adjusting pair 1, and the medium through One or more throttling orifice plates 5 are arranged in the holes 4 . The spherical valve core body 1 is made of integral Stellite3, and the spherical valve core body 3 is connected with the valve stem through the valve stem interface 2, and the valve stem drives the spherical valve core body 3 to rotate. Such as image 3 As shown, when the valve stem drives the spherical valve body 3 to switch and rotate, the medium flow area of the spherical adjusting pair 1 increases or decreases continuously, and the medium passes through the orifice of the spherical adjusting pair 1 and the orifice of the orifice plate 5 in turn. , to carry out multiple throttling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com