Skin rejuvenation base of cosmetic raw material and preparation method thereof

A technology for cosmetics and base, which is applied to the field of cosmetic raw material skin rejuvenation base and its preparation, can solve the problems of increasing skin sensitization probability, production cost, waste of resources, etc., and achieves excellent stability and compatibility, wide application range and convenient use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The present invention provides a cosmetic raw material skin rejuvenation base, comprising the following steps:

[0022] 1) Clean and disinfect the main pot and stainless steel container;

[0023] 2) Pump 99 g of distilled water into the main pot, add sodium hydroxide, and prepare an aqueous solution with a pH of 12.50;

[0024] 3) In a stainless steel container, add 0.25g of trehalose, 0.25g of glucose, 0.25g of sucrose, and 0.25g of erythritol, and mix to obtain skin rejuvenation;

[0025] 4) Take 10g of aqueous solution from the main pot, add it to a stainless steel container, heat it with an induction cooker until it is pre-dissolved at 50°C, stir evenly until there are no particles, then add it to the main pot and continue stirring. After passing the inspection, put it in the storage tank in spare.

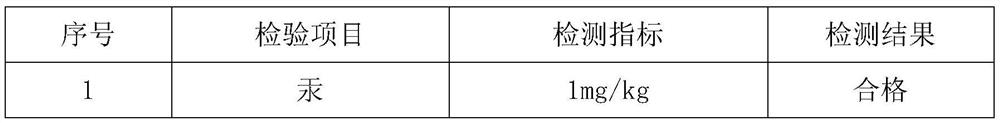

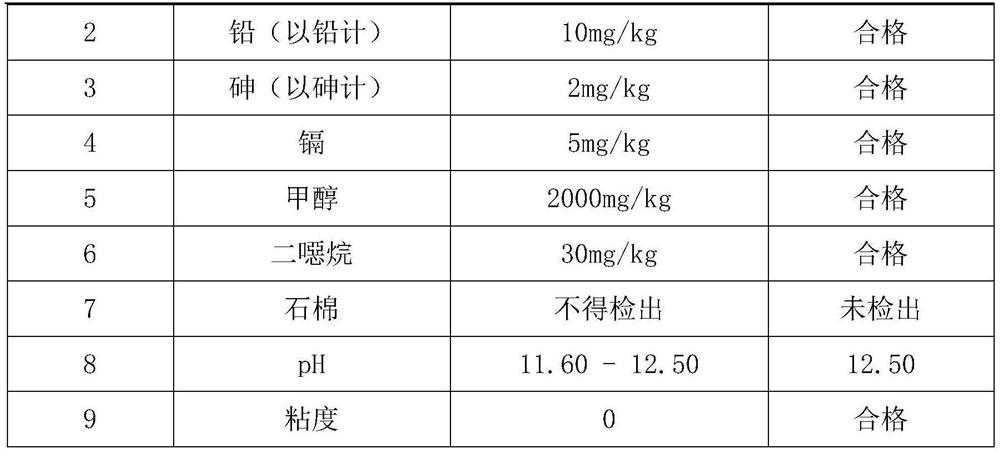

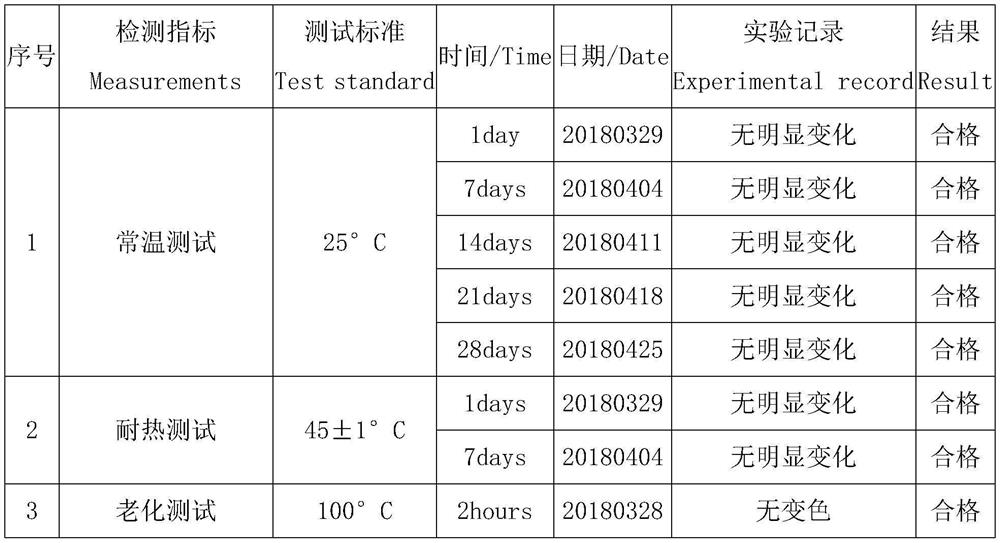

[0026] The products of this embodiment were analyzed for hygienic physical and chemical indicators and microbiological indicators, and the results are shown in Table ...

Embodiment 2

[0040] The present invention provides a cosmetic raw material skin rejuvenation base, comprising the following steps:

[0041] 1) Clean and disinfect the main pot and stainless steel container;

[0042] 2) Pump 98 g of distilled water into the main pot, add sodium hydroxide, and prepare an aqueous solution with a pH of 12.00;

[0043] 3) In a stainless steel container, add 0.5g of trehalose, 0.5g of glucose, 0.5g of sucrose, and 0.5g of erythritol, and mix to obtain skin rejuvenation;

[0044] 4) Take 20g of aqueous solution from the main pot, add it to a stainless steel container, heat it with an induction cooker until it is pre-dissolved at 50°C, stir evenly until there are no particles, then add it to the main pot and continue stirring. After passing the inspection, put it in the storage tank in spare.

Embodiment 3

[0046] The present invention provides a cosmetic raw material skin rejuvenation base, comprising the following steps:

[0047] 1) Clean and disinfect the main pot and stainless steel container;

[0048] 2) Pump 96.8 g of distilled water into the main pot, add sodium hydroxide, and prepare an aqueous solution with a pH of 11.60;

[0049] 3) In a stainless steel container, add 2.0g of trehalose, 1.0g of glucose, 0.1g of sucrose, and 0.1g of erythritol, and mix to obtain skin rejuvenation;

[0050] 4) Take 32g of aqueous solution from the main pot, add it to a stainless steel container, heat it with an induction cooker until it is pre-dissolved at 60°C, stir evenly until there are no particles, then add it to the main pot and continue stirring. After passing the inspection, put it in the storage tank in spare.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com