Novel flour processing equipment

A processing equipment and flour technology, applied in the field of new flour processing equipment, can solve the problems of cumbersome processing procedures, complex structure, cumbersome grinding work, etc., and achieve the effects of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

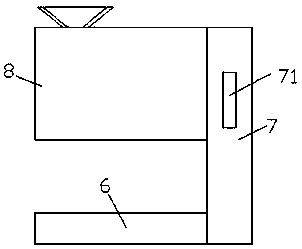

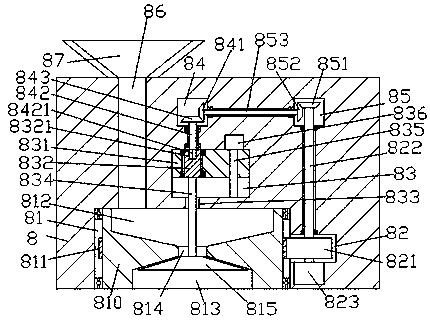

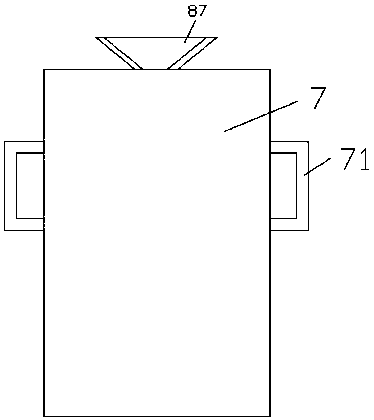

[0014] Combine below Figure 1-Figure 3 The present invention will be described in detail.

[0015] refer to Figure 1-Figure 3 , according to an embodiment of the present invention, a new type of flour processing equipment includes a support frame 7, an underframe 6 fixed on the front end side of the support frame 7, and an upper side of the underframe 6 and connected to the support frame 7. The main base 8 fixedly connected to the front side end face, the left and right sides of the support frame 7 are symmetrically equipped with a hand lift frame 71, the bottom end face of the main base 8 is provided with a recessed groove 81, and the recessed groove 81 rotates Abrasive swivel seat 810 is mated and connected, and a first bevel edge cavity 812 is provided in the top end surface of said abrasive turntable 810, and a second bevel edge cavity 813 is provided in the bottom end surface of said abrasive turntable 810, and said first bevel edge cavity A first port 814 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com