Damping and buffering base

A shock-absorbing layer and bottom surface technology, applied in the direction of springs/shock absorbers, large fixed members, maintenance and safety accessories, etc., can solve problems such as machine tool ground damage, and achieve the effect of extending service life, reducing impact and avoiding deviation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The preferred technical solutions of the present invention will be described in detail below with reference to the drawings.

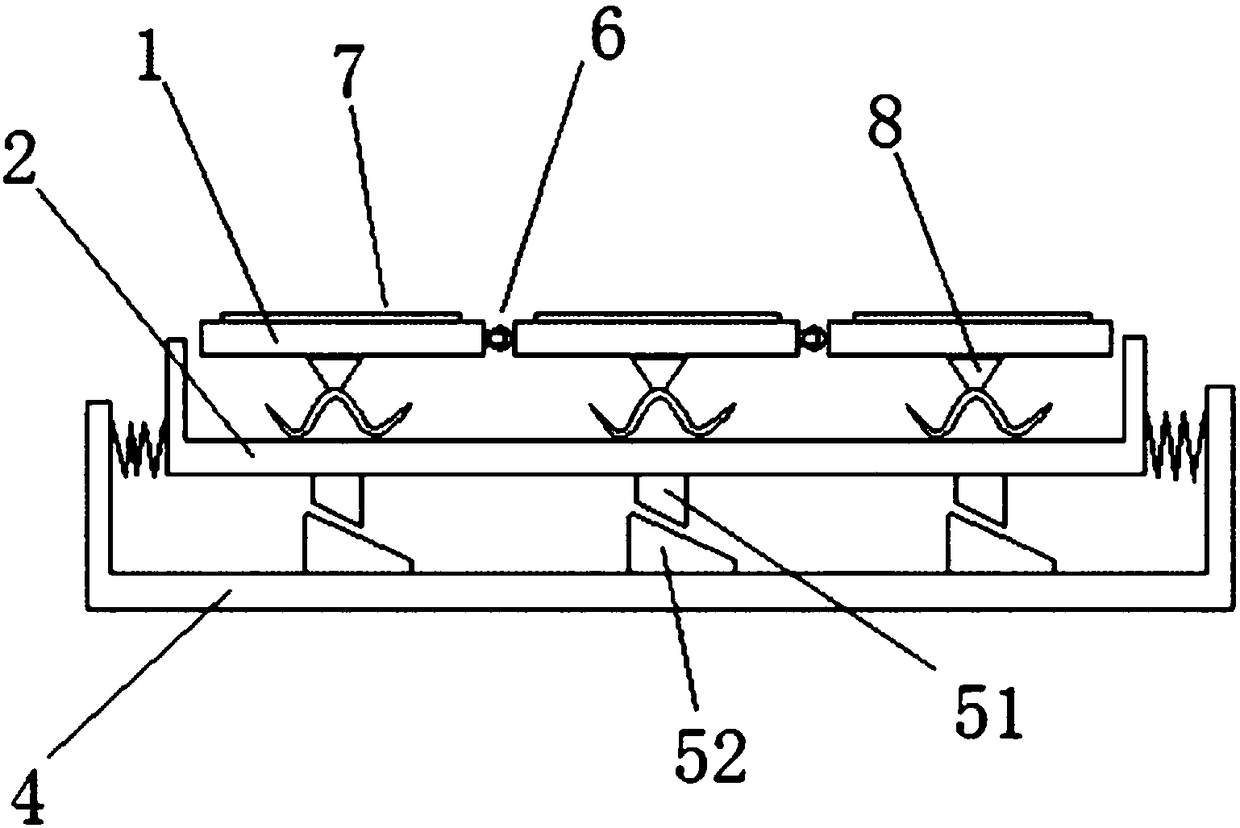

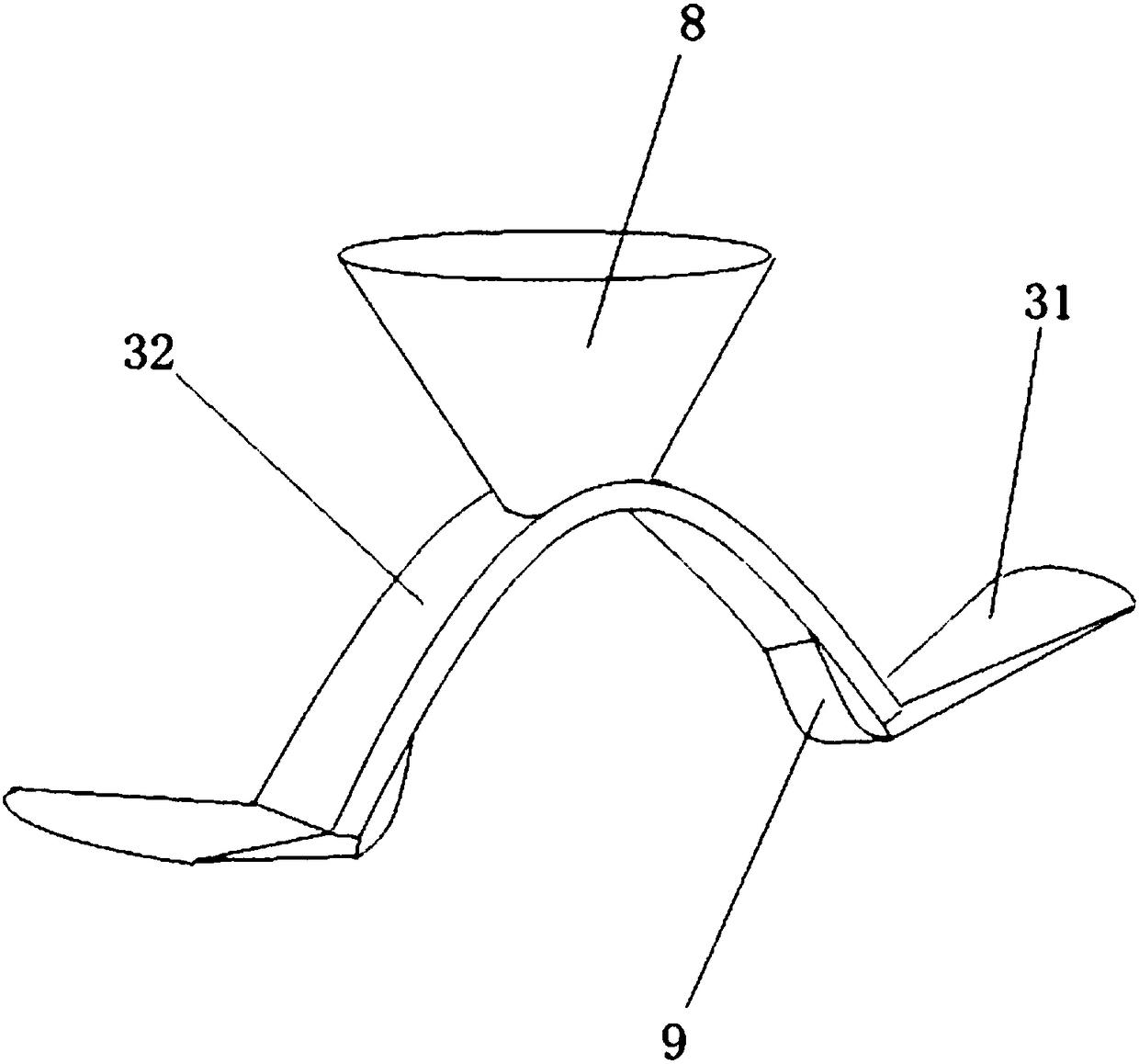

[0024] As shown in the figure, the two-way shock-absorbing buffer base of the machine tool of the present invention includes a segmented layer, a shock-absorbing layer and a compression layer arranged from top to bottom. The segmented layer is used to directly contact the mechanical equipment. Absorb and transmit the vibration generated by the equipment, while the shock-absorbing layer begins to completely absorb and disperse the remaining vibration force, and at the same time block the transmitted vibration rebound. The pressure-resistant layer is mainly used for the instant when the workpiece on the equipment is installed or dropped. The resulting gravity is also an important blockade to prevent vibration from other places on the ground from being transmitted to the machine tool.

[0025] The segmented layer is in contact with the bottom of the mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com