Double-layer foaming composite adsorption film for sewage treatment and preparation method thereof

A composite adsorption and sewage treatment technology, applied in water/sewage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of single adsorption type, low adsorption efficiency, and low labor efficiency, and achieve High adsorption efficiency, many adsorption channels, and the effect of improving labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

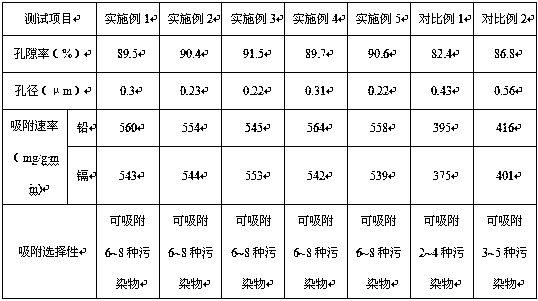

Examples

Embodiment 1

[0034] a. Mixing foaming agent with porous ceramics, forming a polyvinyl alcohol film layer on the surface of the mixed particles by spray precipitation method, to obtain foaming agent / porous ceramic microcapsules;

[0035] b, mixing foaming agent with diatomite, adopting spray precipitation method to form polyvinyl alcohol film layer on the surface of mixed particles, making foaming agent / diatomite microcapsule;

[0036] c, mixing the foaming agent / porous ceramic microcapsules prepared in step a with polyurethane prepolymer and ethylene / vinyl acetate copolymer to prepare mixture A;

[0037] d, mixing the blowing agent / diatomite microcapsules prepared in step b with polyurethane prepolymer and ethylene / vinyl acetate copolymer to prepare mixture B;

[0038]e. Extrude compound A and compound B through double-layer co-extrusion equipment to form a film, and obtain a double-layer film composed of polyurethane and ethylene / vinyl acetate copolymer, which is a double-layer film for s...

Embodiment 2

[0043] a. Mixing foaming agent with porous ceramics, forming a polyvinyl alcohol film layer on the surface of the mixed particles by spray precipitation method, to obtain foaming agent / porous ceramic microcapsules;

[0044] b, mixing foaming agent with diatomite, adopting spray precipitation method to form polyvinyl alcohol film layer on the surface of mixed particles, making foaming agent / diatomite microcapsule;

[0045] c, mixing the foaming agent / porous ceramic microcapsules prepared in step a with polyurethane prepolymer and ethylene / vinyl acetate copolymer to prepare mixture A;

[0046] d, mixing the blowing agent / diatomite microcapsules prepared in step b with polyurethane prepolymer and ethylene / vinyl acetate copolymer to prepare mixture B;

[0047] e. Extrude compound A and compound B through double-layer co-extrusion equipment to form a film, and obtain a double-layer film composed of polyurethane and ethylene / vinyl acetate copolymer, which is a double-layer film for ...

Embodiment 3

[0052] a. Mixing foaming agent with porous ceramics, forming a polyvinyl alcohol film layer on the surface of the mixed particles by spray precipitation method, to obtain foaming agent / porous ceramic microcapsules;

[0053] b, mixing foaming agent with diatomite, adopting spray precipitation method to form polyvinyl alcohol film layer on the surface of mixed particles, making foaming agent / diatomite microcapsule;

[0054] c, mixing the foaming agent / porous ceramic microcapsules prepared in step a with polyurethane prepolymer and ethylene / vinyl acetate copolymer to prepare mixture A;

[0055] d, mixing the blowing agent / diatomite microcapsules prepared in step b with polyurethane prepolymer and ethylene / vinyl acetate copolymer to prepare mixture B;

[0056] e. Extrude compound A and compound B through double-layer co-extrusion equipment to form a film, and obtain a double-layer film composed of polyurethane and ethylene / vinyl acetate copolymer, which is a double-layer film for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap