System and method for handling splashing of converter

A converter and nozzle technology, applied in the field of converter dust removal, can solve the problems of poor dust removal effect, achieve the effect of eliminating flue gas volume and dust, avoiding environmental pollution, and eliminating splashing phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

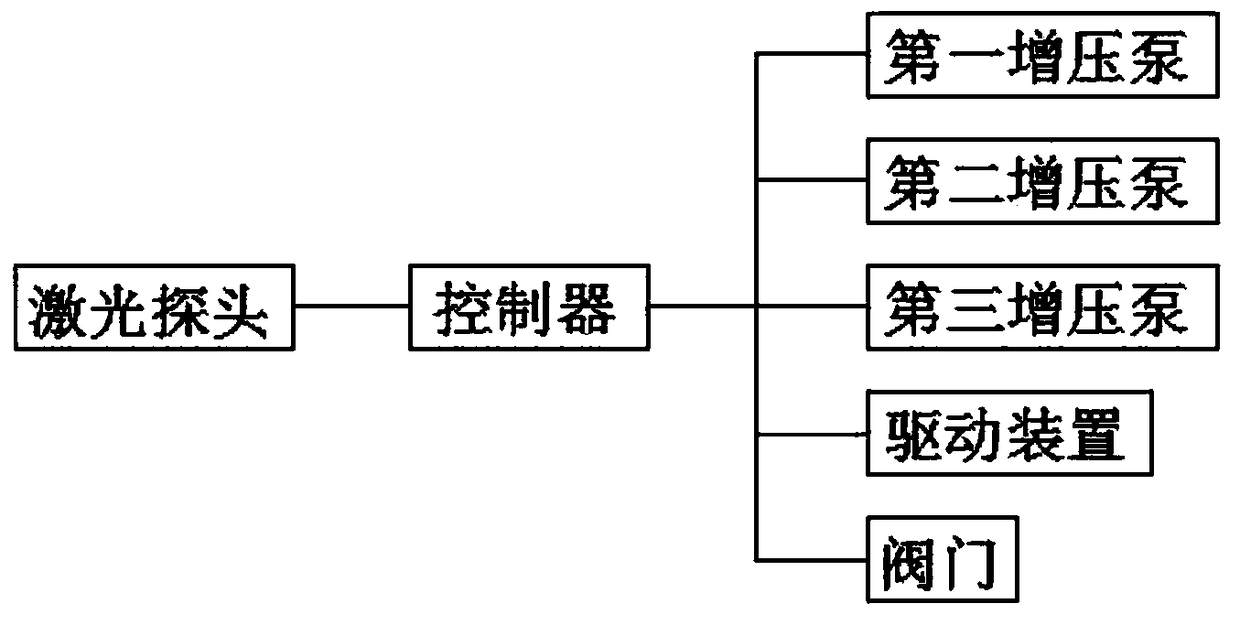

[0039] Such as figure 1 As shown, the system for dealing with converter splashing in this embodiment includes a laser probe, a controller, a first booster pump, a second booster pump, a third booster pump, a driving device and a valve;

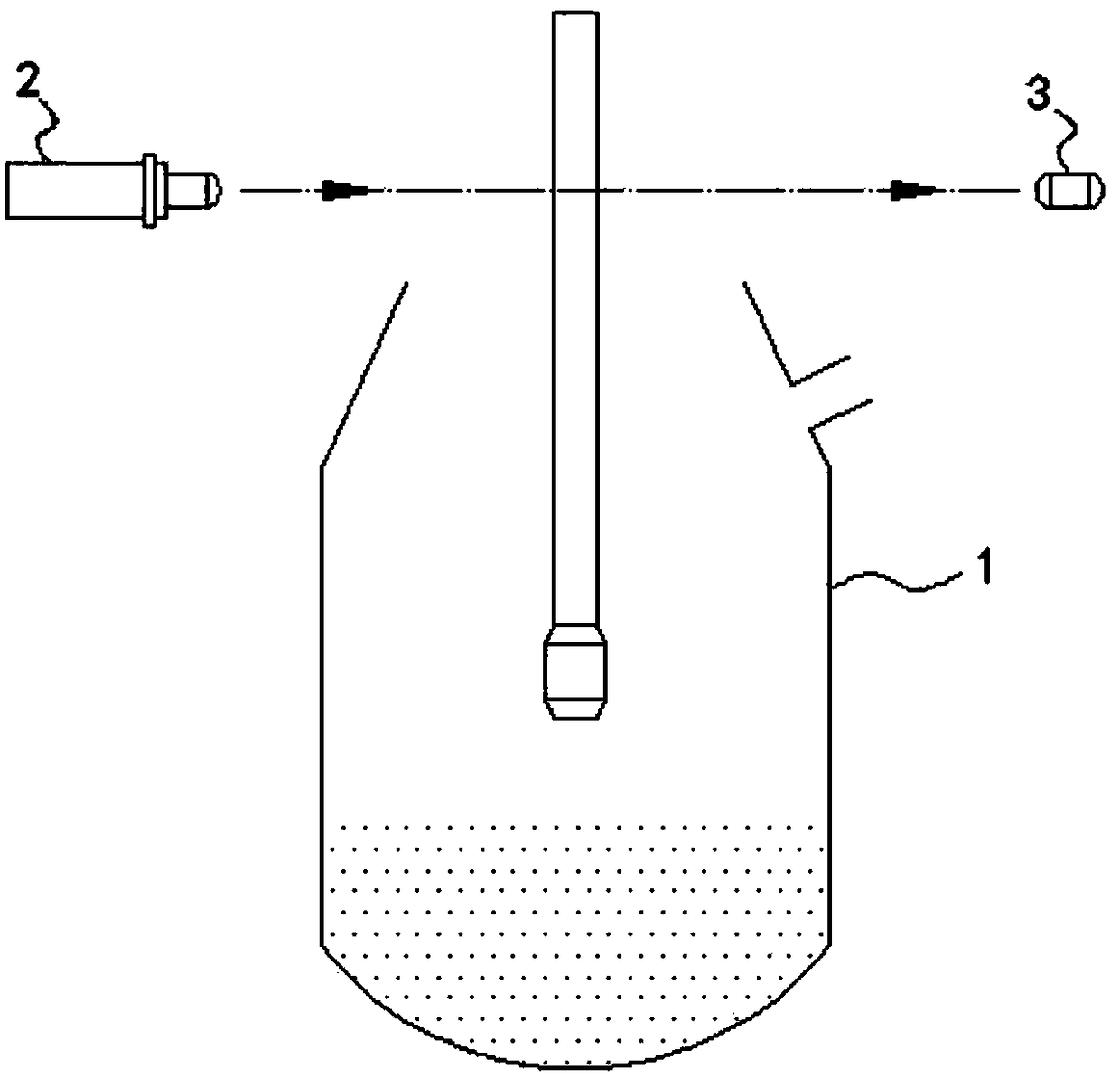

[0040] Such as figure 2 As shown, the laser probe is installed at the furnace mouth of the converter 1, and the transmitter 2 and receiver 3 of the laser probe are respectively located on both sides of the furnace mouth. The laser emitted by the transmitter 2 passes through the flue gas of the furnace mouth, and the receiver 3 Measure the dust content in the flue gas at the furnace mouth according to the intensity of the received laser and transmit the measurement results to the controller;

[0041] The system for dealing with converter splash in this embodiment is used in the old OG dedusting device, and the structure of the old OG dedusting device is as follows image 3 As shown, the old OG dedusting device includes a vaporization flue, a...

Embodiment 2

[0051] The system for dealing with converter spatter in this embodiment includes a laser probe, a controller, a first booster pump, a second booster pump, a third booster pump, a driving device and a valve;

[0052] The system for dealing with converter splashing in this embodiment is used in a new OG dedusting device, and the structure of the new OG dedusting device is as follows Figure 4 As shown, the new OG dedusting device includes vaporization flue, spray tower, annular venturi tube, dehydrator and fan, and the flue gas discharged from the converter passes through vaporization flue, spray tower, annular venturi tube, dehydrator and fans;

[0053] The first booster pump is installed on the nozzle water supply pipeline of the spray tower, the second booster pump is installed on the nozzle water supply pipeline of the annular venturi tube, and the third booster pump is installed on the water supply pipeline of the front nozzle of the dehydrator ;

[0054] The driving devi...

Embodiment 3

[0057]The system for dealing with converter spatter in this embodiment includes a laser probe, a controller, a first booster pump, a second booster pump, a third booster pump, a driving device and a valve;

[0058] The system for dealing with converter splash in this embodiment is used for old OG semi-dry dedusting device, such as Figure 5 As shown, the old OG semi-dry wet electrostatic precipitator includes a vaporization flue, an evaporative cooling tower, a first-stage venturi tube, a second-stage flap venturi tube, a dehydrator and a fan, and the flue gas discharged from the converter passes through the vaporization flue in turn , evaporative cooling tower, primary venturi tube, secondary flap venturi tube, dehydrator and fan;

[0059] The first booster pump is installed on the nozzle water supply pipeline of the first-stage venturi tube, the second booster pump is installed on the nozzle water supply pipeline of the second-stage flap venturi tube, and the third booster p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com