Blade for slab deburring machine and manufacturing method thereof

A deburring machine and blade technology, applied in the direction of manufacturing tools, coatings, furnace types, etc., can solve the problems of peeling and breaking, easy wear and tear, unable to meet the high precision requirements of the burr of the casting billet, and achieve the effect of good metallic luster.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

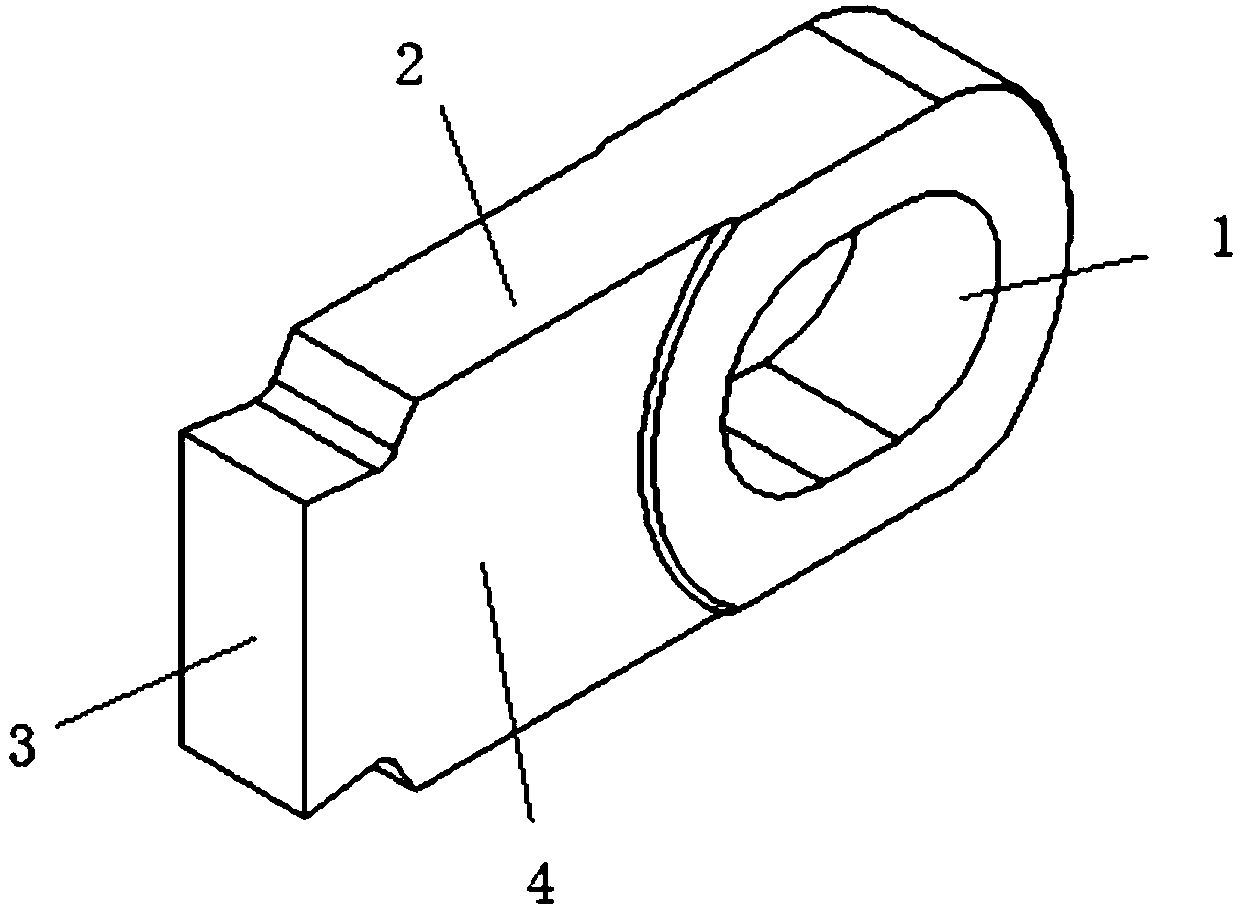

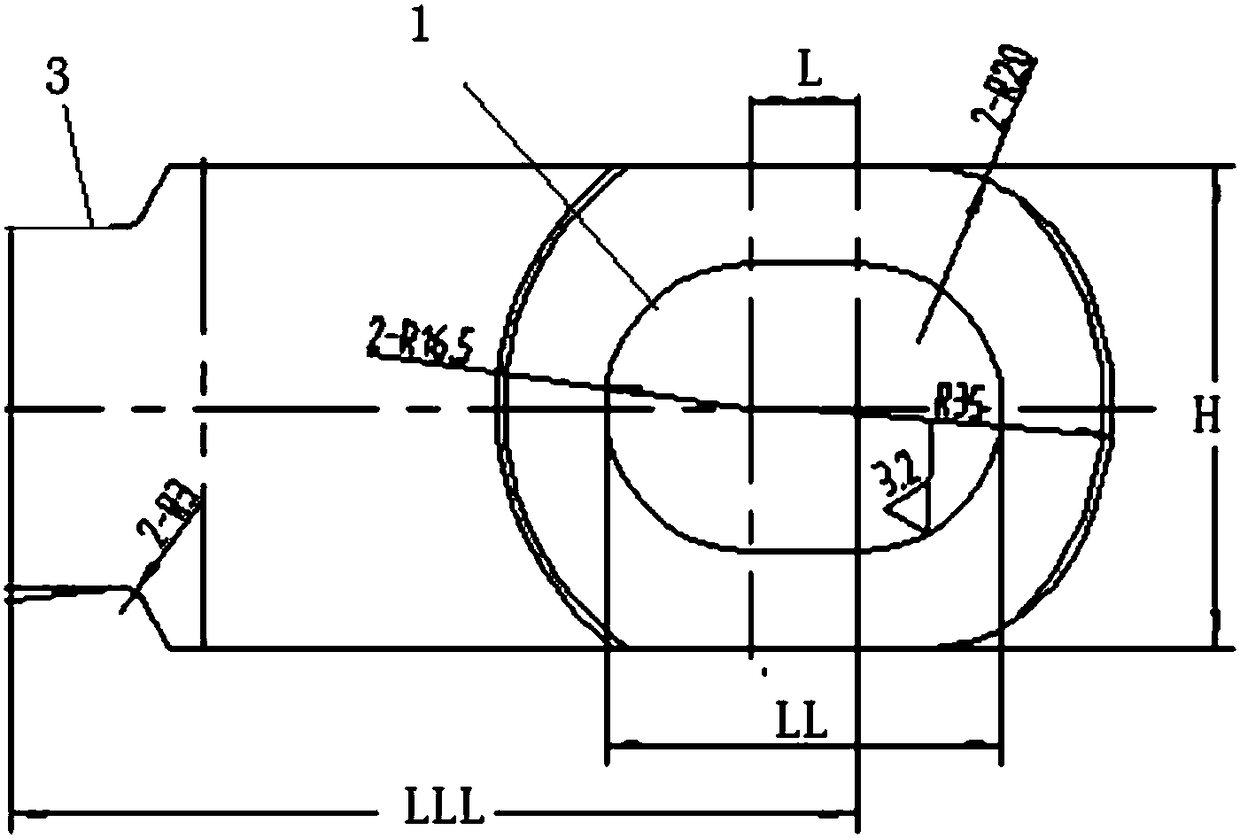

[0019] The following is based on Figure 1-2 The present invention is further described.

[0020] figure 1 The middle blade 4 is flat, and the upper and lower ribs 2 of the blade along the length direction are respectively two faces. Along the length direction, the end far away from the cutter head 3 is provided with a rectangular oval hole or a waist-shaped hole 1, and the semicircle of the waist-shaped hole 1 A clearance fit is used between the diameter and the blade shaft, and the diameter of the semicircle is larger than the diameter of the blade shaft.

[0021] figure 2 for figure 1 The front view of the middle blade 4 is also a structural dimension diagram. In order to facilitate the return of the blade, the length direction of the blade is designed as two surfaces up and down, so that the whole blade becomes flat. In this embodiment, the thickness of the preferred blade is 22mm , and can also be adjusted as needed. In order to reduce the resistance of the blade mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com