Particle-group idler wheel synergistic tuned damper

A damper and particle swarm technology, which is applied to bridge parts, bridges, building components, etc., can solve the problems of single control direction and narrow vibration reduction frequency band, and achieve the effects of reducing damage, vibration reduction frequency bandwidth, and increasing effective collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

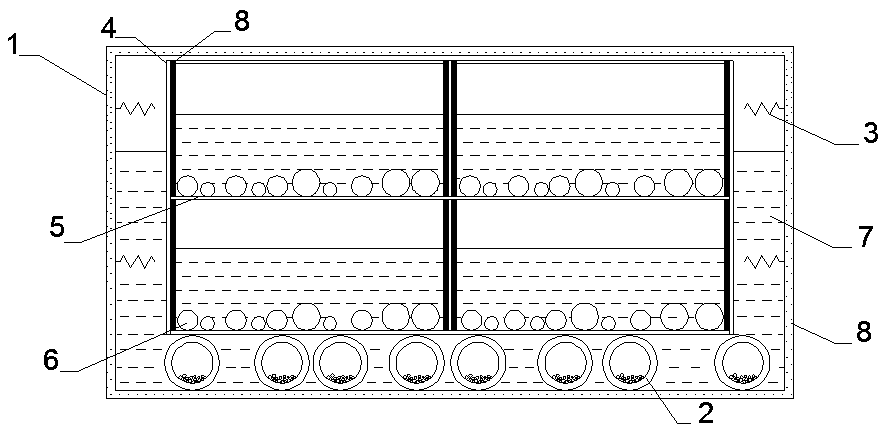

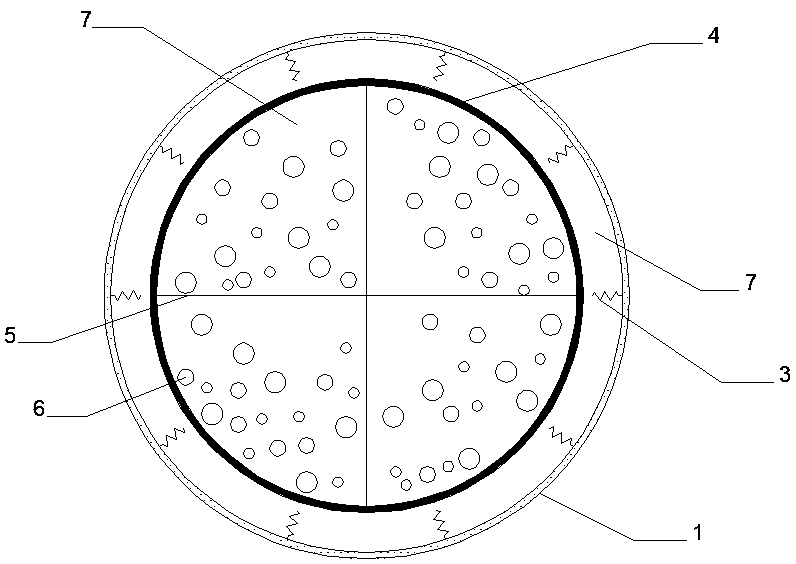

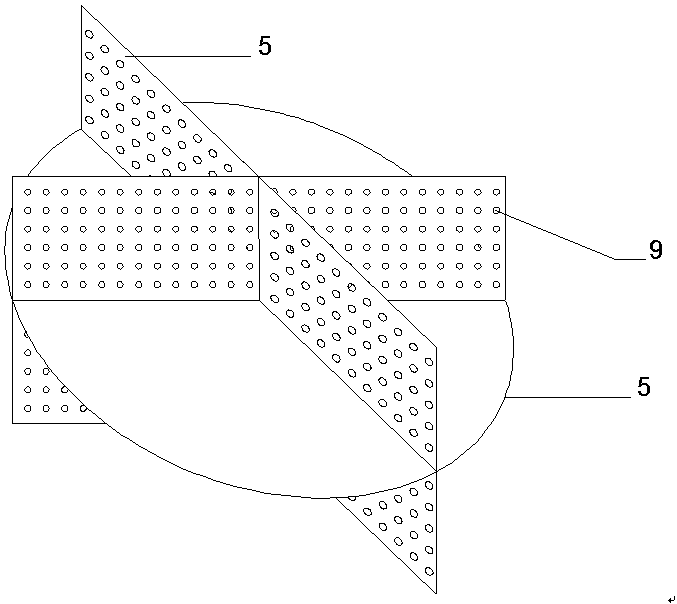

[0021] Example 1: Such as figure 1 As shown, the present invention is a particle swarm coordinated tuned damper, which mainly includes: the outer cavity unit of the damper 1, the nested particle swarm 2, the limit spring 3, the inner cavity unit 4, and the metal partition 5 , Damping particles 6, viscous liquid 7, and cushioning material 8. The outer cavity unit 1 and the inner cavity unit 4 of the damper are tightly welded by steel plates. The inner wall and bottom of the outer cavity unit 1 and the inner and outer sides of the inner cavity unit 4 are all coated with anti-rust paint to prevent the steel plate from corroding; The external cavity unit 1 is connected to the main structure through a high-strength bolt connection. The inner wall and bottom of the outer cavity unit 1 are pasted with cushioning material 8. The inner cavity unit 4 can slide back and forth on the inner bottom surface of the outer cavity unit 1 through the nested particle group 2 as a roller, the nested...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com