A connection device for a prefabricated staircase, a prefabricated staircase and an installation method thereof

A technology of connection device and installation method, which is applied in the direction of stairs, building materials processing, construction, etc., can solve the problem that the stair section slab cannot meet the seismic force of the diagonal bracing at the same time, and achieve the effect of reducing adverse effects and avoiding shear damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

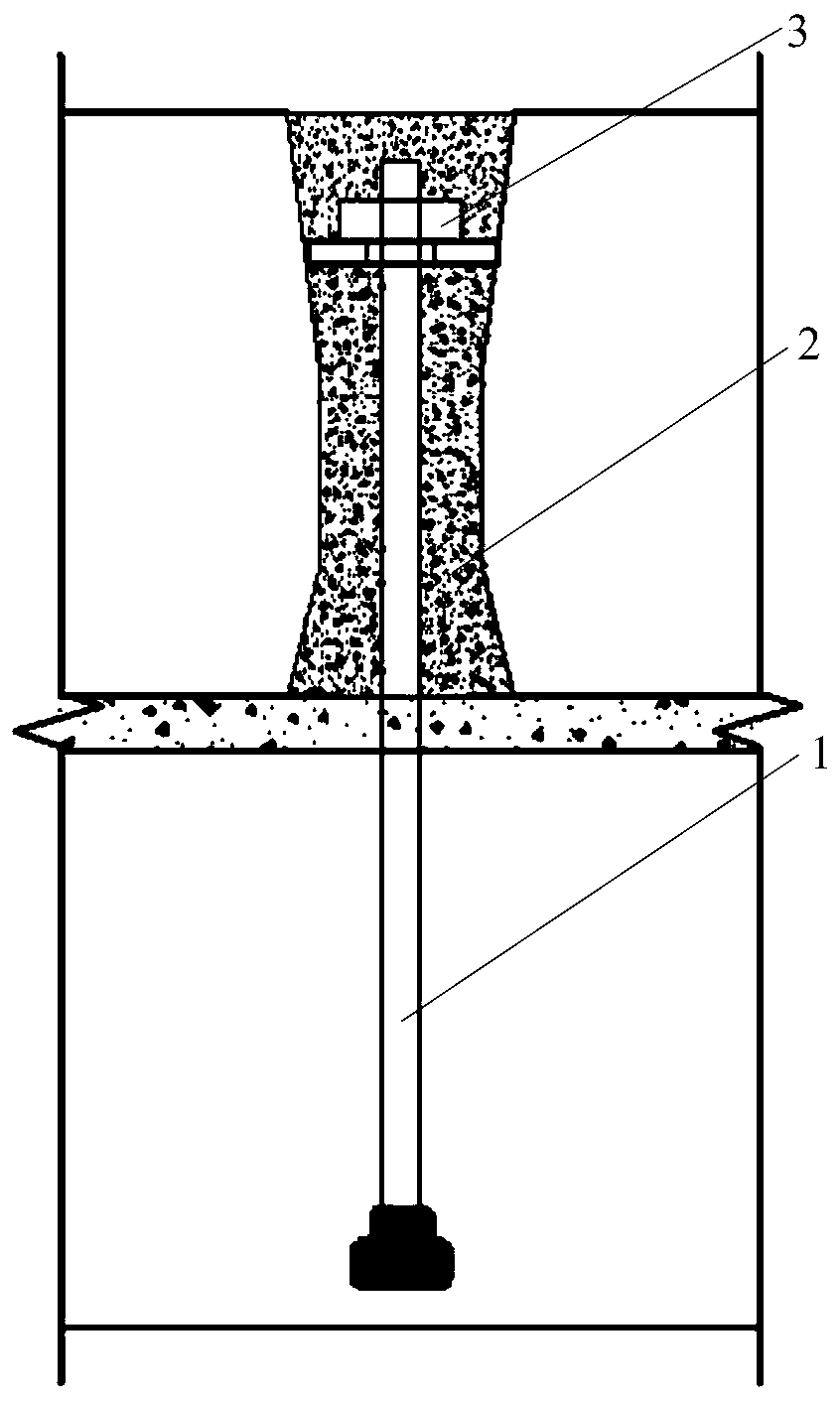

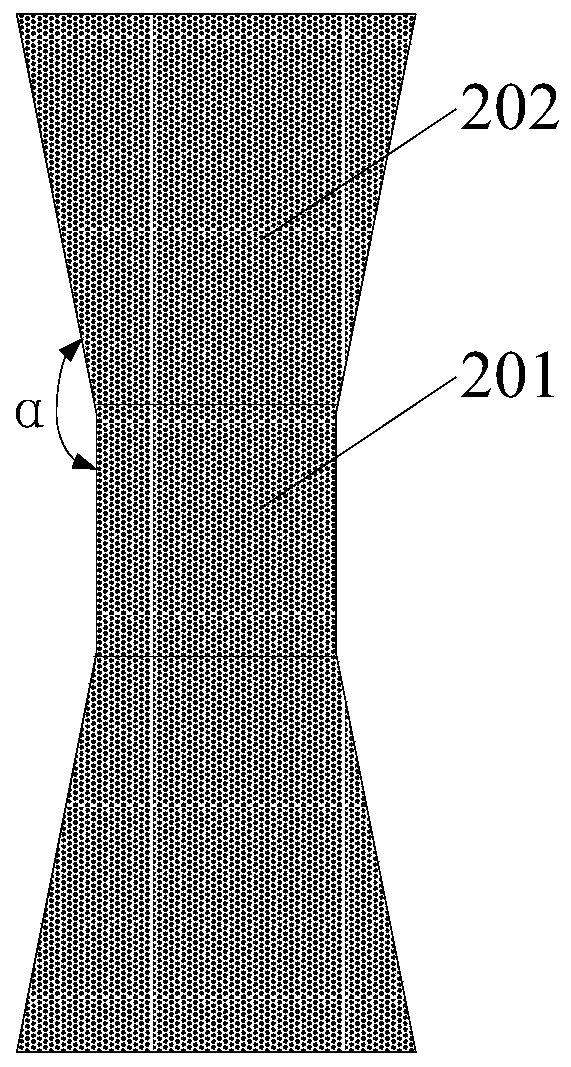

[0039] This embodiment provides a connecting device for an assembled staircase, such as Figure 2 to Figure 4 As shown, it includes a bolt 1 , an elastic filling member 2 sleeved on the upper part of the bolt 1 and a nut 3 fixedly connected to the upper end of the bolt 1 , and the shape of the elastic filling member 2 is dumbbell-shaped.

[0040] It should be noted that the so-called dumbbell shape is a cylindrical shape with a diameter at both ends greater than that in the middle, that is to say, the elastic pouring part 2 is a cylindrical shape with two ends larger than the middle.

[0041] When in use, the lower part of the bolt 1 is inserted into the corbel of the prefabricated staircase, and the step plate 4 of the prefabricated staircase is provided with a pouring hole matching the shape of the elastic pouring part 2, and the upper part of the bolt 1 is inserted into the pouring hole , and then inject the elastic pouring material into the pouring hole to form the elastic...

Embodiment 2

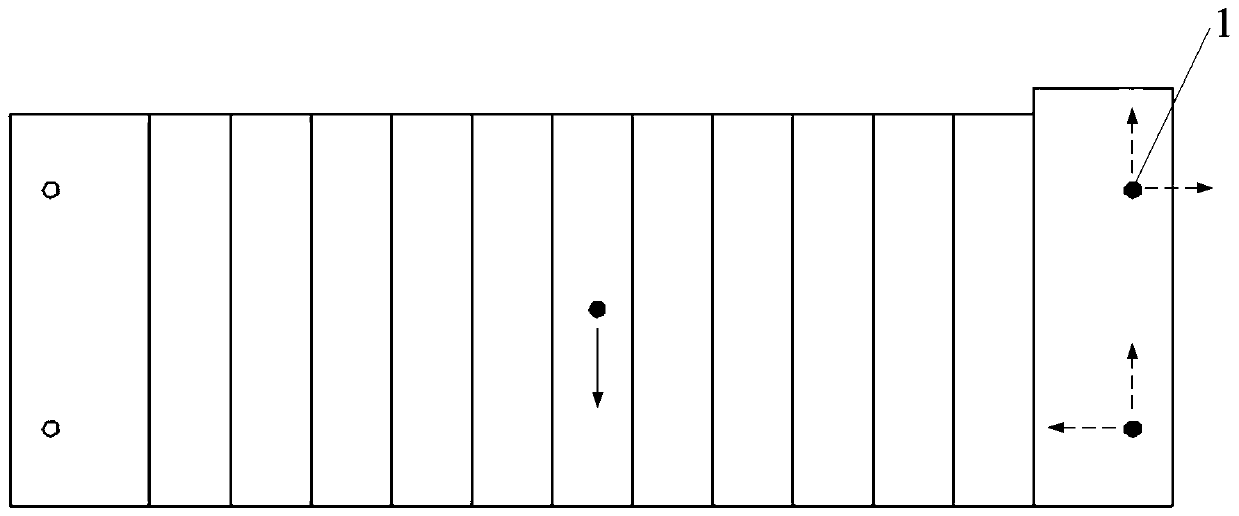

[0049] This embodiment provides a kind of prefabricated staircase, such as Figure 5 to Figure 7 As shown, it includes a plurality of stair slabs 4 connecting up and down, and the junction of two adjacent stair slabs 4 is provided with a ladder beam 5 and a corbel 7, and the lower end surface of the ladder beam 5 is fixed to the upper end surface of the corbel 7. connection, the corbel 7 protrudes from the side of the ladder beam 5, and the two ends of the ladder plate 4 respectively rest on the part of the adjacent corbel 7 protruding from the ladder beam, and are fixed to the corbel 7 by the connecting device provided in the first embodiment Connection; the lower part of the bolt 1 is located in the corbel 7 , and the upper part of the bolt 1 , the elastic pouring part 2 and the nut 3 are located in the stair plate 4 .

[0050] Compared with the prior art, in the prefabricated staircase provided by this embodiment, the upper and lower ends of the stair plate 4 are connected ...

Embodiment 3

[0058] This embodiment provides a method for installing a prefabricated staircase, including the following steps:

[0059] Step 1: Pouring the ladder beams and corbels, when pouring the corbels, fix the lower part of the bolts in the corbels;

[0060] Step 2: After the ladder beams and corbels reach the design strength, lay a leveling layer with a thickness of 18mm to 22mm on the corbels, usually using 1:1 cement mortar for leveling;

[0061] Step 3: Lift the stair slab to the target position, place it in place accurately, the error control meets the specification requirements, and insert the upper part of the bolt into the pouring hole of the stair slab;

[0062] Step 4: Inject elastic perfusion material into the perfusion hole, and form an elastic perfusion part after the elastic perfusion material is shaped;

[0063] Step 5: Screw the nut on the upper end of the bolt to fill the filling hole;

[0064] Step 6: Leave a gap between the stair slab and the ladder beam. The siz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com