Perforating gun and machining method for gun body of perforating gun

A perforating gun and gun body technology, which is applied in the direction of production fluid, earthwork drilling, wellbore/well parts, etc., can solve the problem that it is difficult to ensure that the perforating bullet enters the oil reservoir to be shot, and it is difficult to use a round tube gun body Accurate positioning, affecting fracturing construction and other issues, to achieve the effect of increasing oil and gas production, reducing the possibility of well stuck accidents, and having a good supporting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

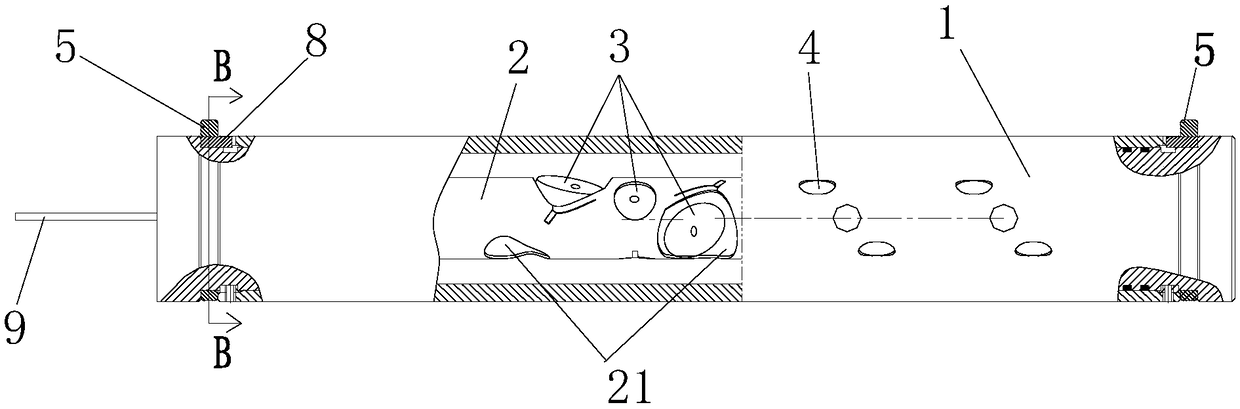

[0046] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

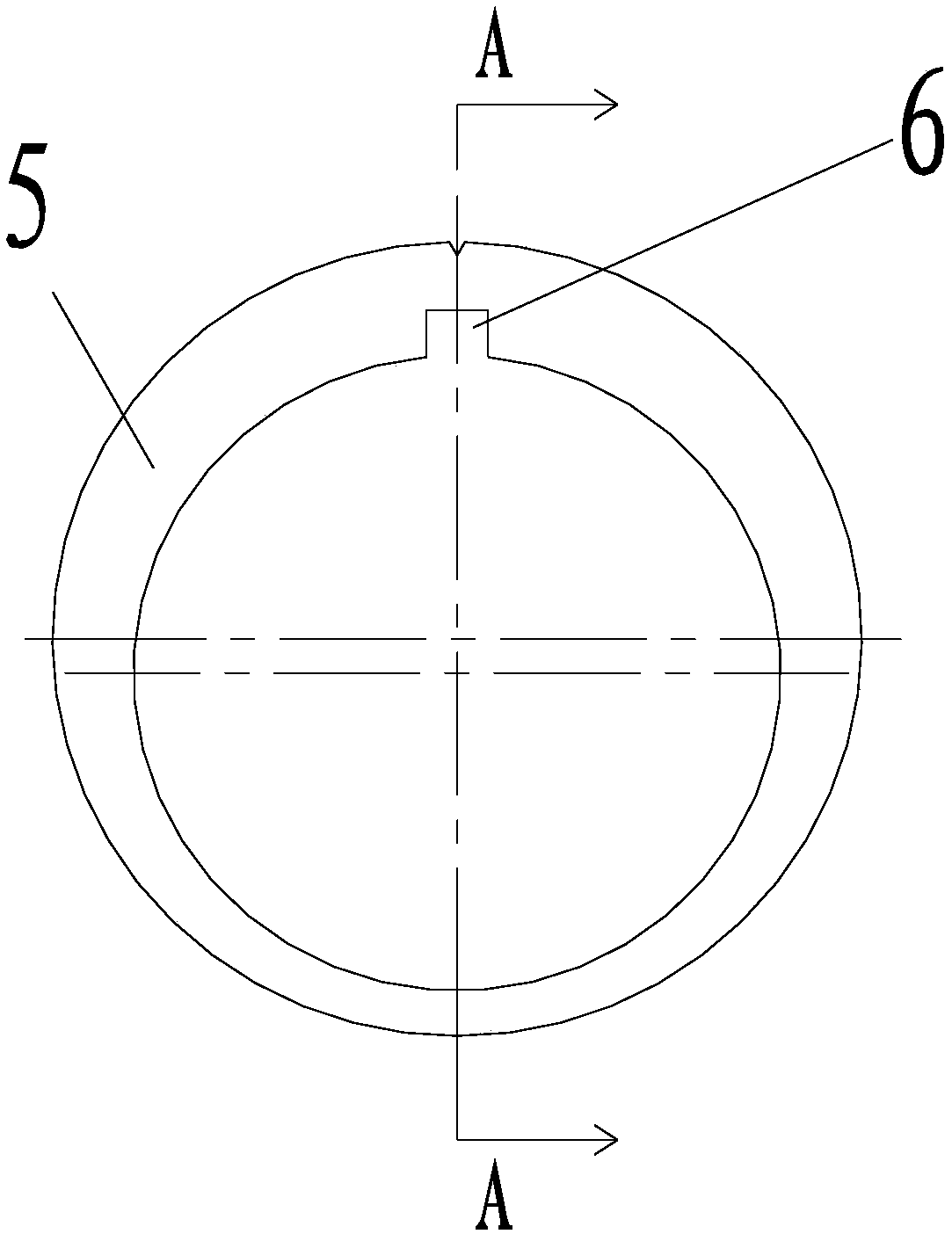

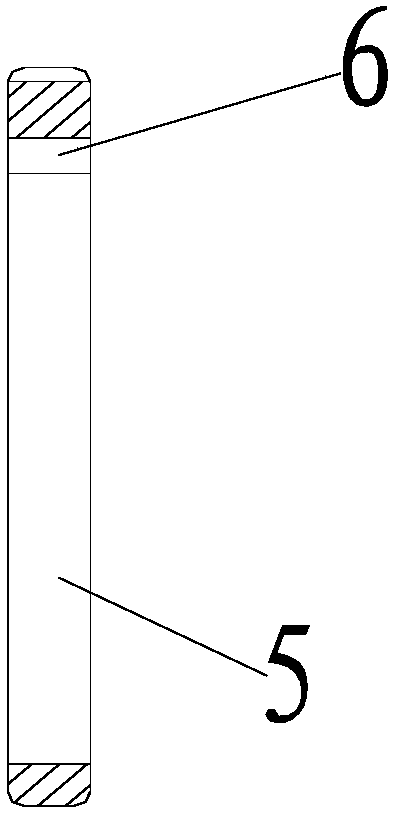

[0047] see image 3 , Figure 4 with Image 6 , a perforating gun, including a gun body 1, a bullet rack 2 is arranged in the gun body 1, and a perforating bullet 3 is fixed on the bullet rack 2.

[0048] The bomb holder 2 is a metal tube, and the metal tube is provided with a plurality of cutouts 21, and the perforating charges are installed on the cutouts 21 one by one; three cutouts 21 form a group, and the three cutouts 21 are spirally distributed in the On the metal pipe; the perforating charges installed in the middle of each group of cuts are perpendicular to the axis of the metal pipe, and the perforating charges 3 installed at both ends of each group of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com