Method for adjusting resistance of ventilation dust removal pipe

A technology of pipeline resistance and resistance, applied in the direction of pipe elements, pipes/pipe joints/pipe fittings, instruments, etc., can solve the problems of dust settling, clogging, pumping, high price, etc., and achieves convenient replacement of orifice plates, convenient operation, and air tightness. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to specifically understand the content of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to the following examples.

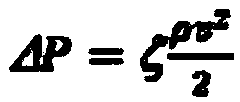

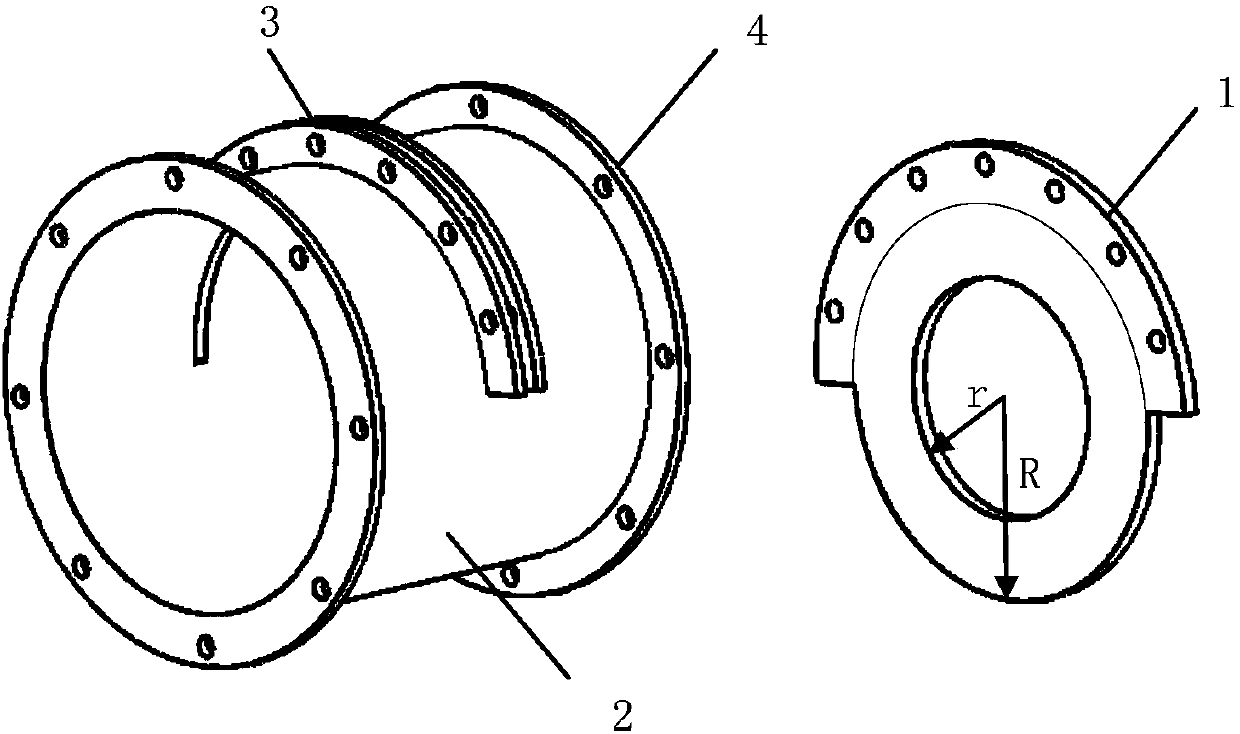

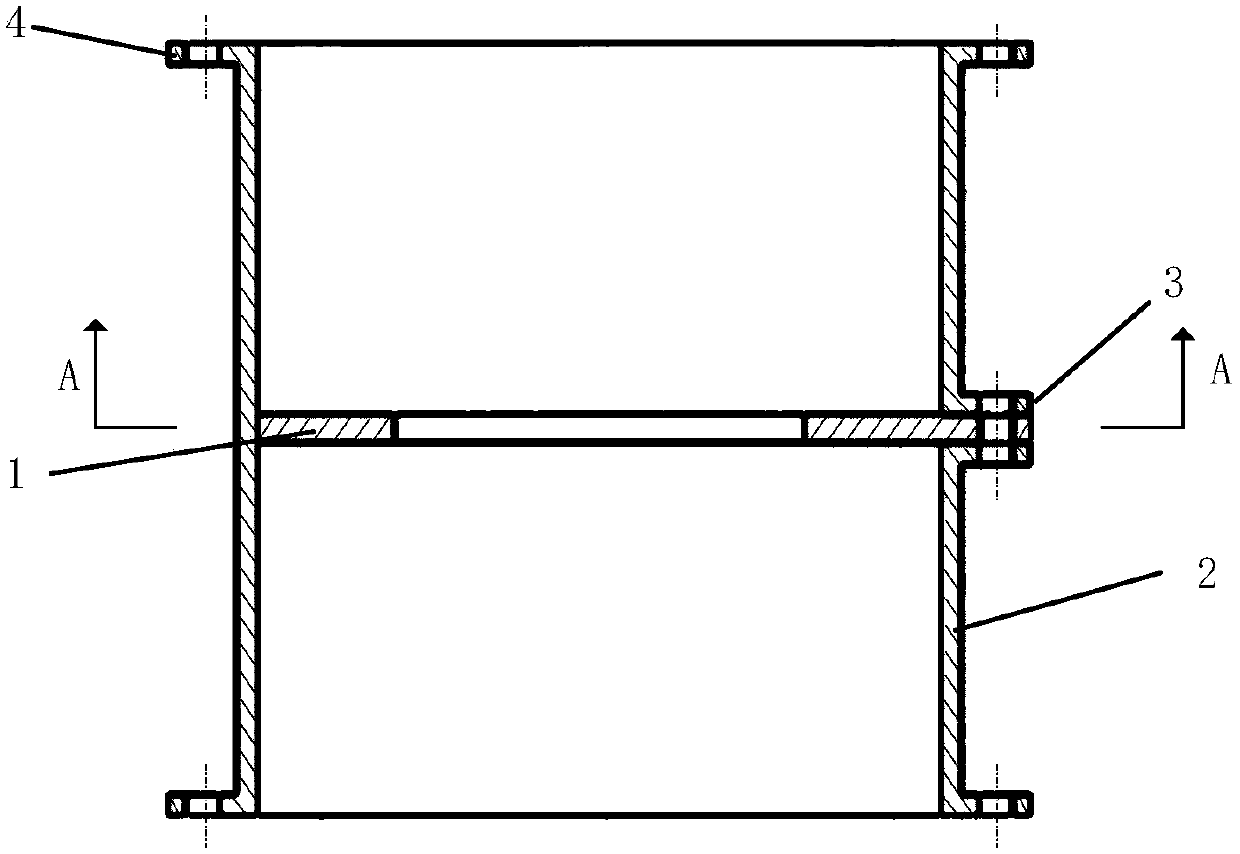

[0024] Such as figure 1 , figure 2 , image 3 As shown, the adjustable orifice resistance balancer designed by the present invention includes a short pipe 2 connected to the ventilation and dust removal pipe network, and an orifice insert 1 for resistance balance adjustment. The upper part of the short tube 2 has a 1 / 2 opening, and the width of the opening is consistent with the width of the orifice plate, which can be used for the insertion of the orifice plate insert 1. The orifice plate inserts with different aperture ratios cause different local resistance in the pipe network, so the orifice plate inserts with different aperture ratios can be used to adjust when the resistance of the pipe network...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap