Production line for steel wire coating

A production line and steel wire technology, which is applied in the field of optical cable production, can solve problems such as fiber breakage and steel wire easy loosening, and achieve the effects of smaller shrinkage, enhanced tensile strength, and improved overhead performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

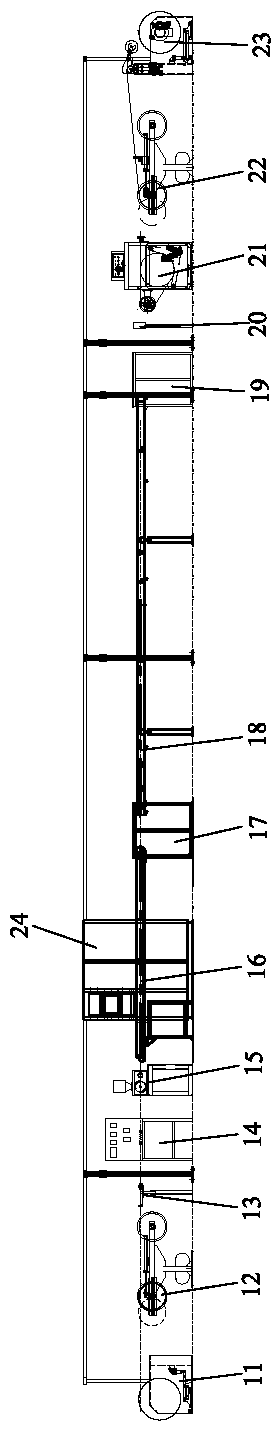

[0022] Please refer to figure 1 As shown, it has shown the specific structure of the preferred embodiment of the present invention, including pay-off machine 11, the first tension dancing device 12, dust removal device 13, steel wire heating device 14, extrusion host 15, mobile warm water tank 16, Warm water tank 17, fixed water tank 18, cold water tank 19, outer diameter caliper 20, drawing machine 21, second tension dancing device 22, wire take-up machine 23 and main control electric box 24.

[0023] The pay-off machine 11, the first tension dancing device 12, the dust removal device 13, the steel wire heating device 14, the extrusion host 15, the mobile warm water tank 16, the warm water tank 17, the fixed water tank 18, the cold water tank 19, the outer diameter gauge 20, The drawing machine 21, the second tension dance device 22 and the wire take-up machine 23 are arranged side by side in sequence, and the main control electric box 24 controls the wire pay-off machine 11,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com