Solar cell and its preparation method

A solar cell and battery technology, applied in the field of solar cells, can solve problems such as reducing the electrical performance of solar cells, and achieve the effects of reducing the contact area, reducing the recombination center, and improving the electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

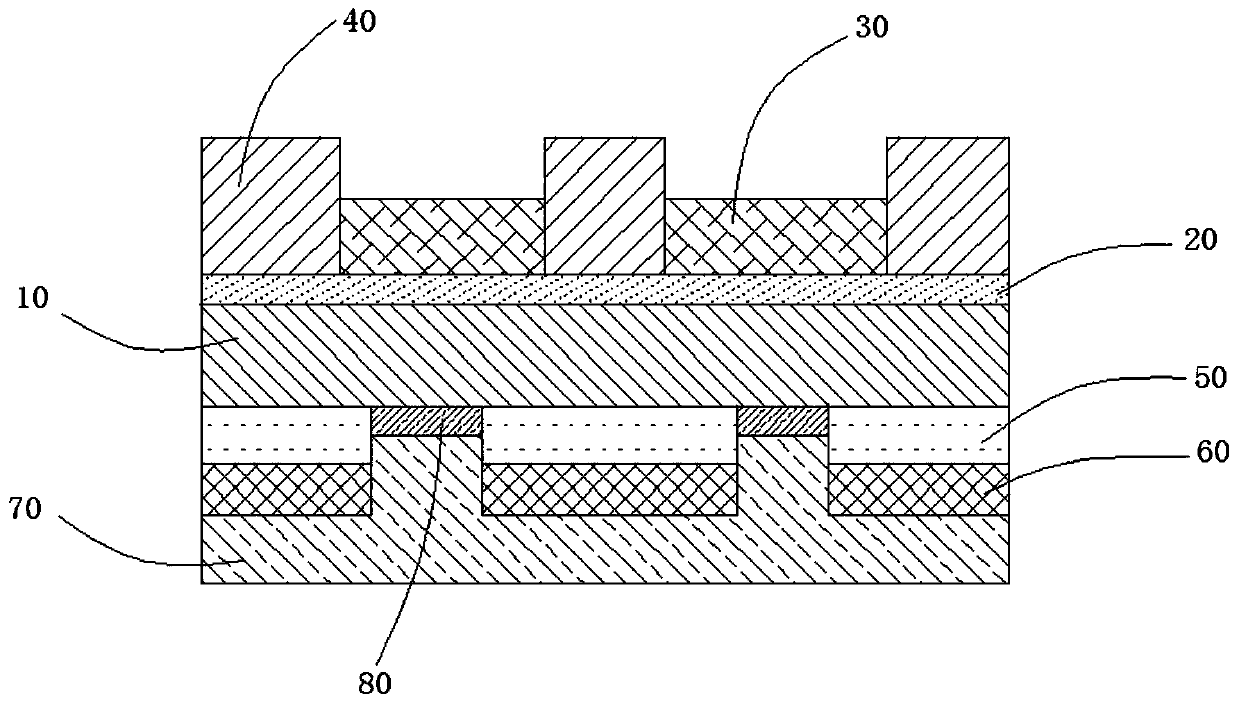

[0059] Such as figure 1 As shown, this embodiment is a solar cell, including the following parts:

[0060] 1) P-type silicon chip 10: resistivity 2Ω·cm, as an absorbing layer, converts photons that meet the conditions into electrons, and the size of the P-type silicon chip is 2×2cm 2 ;

[0061] 2) n+ diffusion layer 20: also known as the emitter, the main function is to form a p-n junction with p-Si to selectively transport electrons, with a depth of about 0.5 μm, using POCl 3 As a phosphorus source, it is prepared by diffusion in a tube furnace;

[0062] 3) Silicon nitride anti-reflection film 30: deposited by PECVD, with a thickness of about 75nm;

[0063] 4) Negative electrode 40: obtained by screen printing and high-temperature sintering, used to transport carriers;

[0064] 5) Al 2 o 3 Passivation layer 50: prepared by atomic layer deposition, with a thickness of about 5nm, used to passivate p-type silicon wafers;

[0065] 6) Silicon nitride layer 60: prepared by P...

Embodiment 2

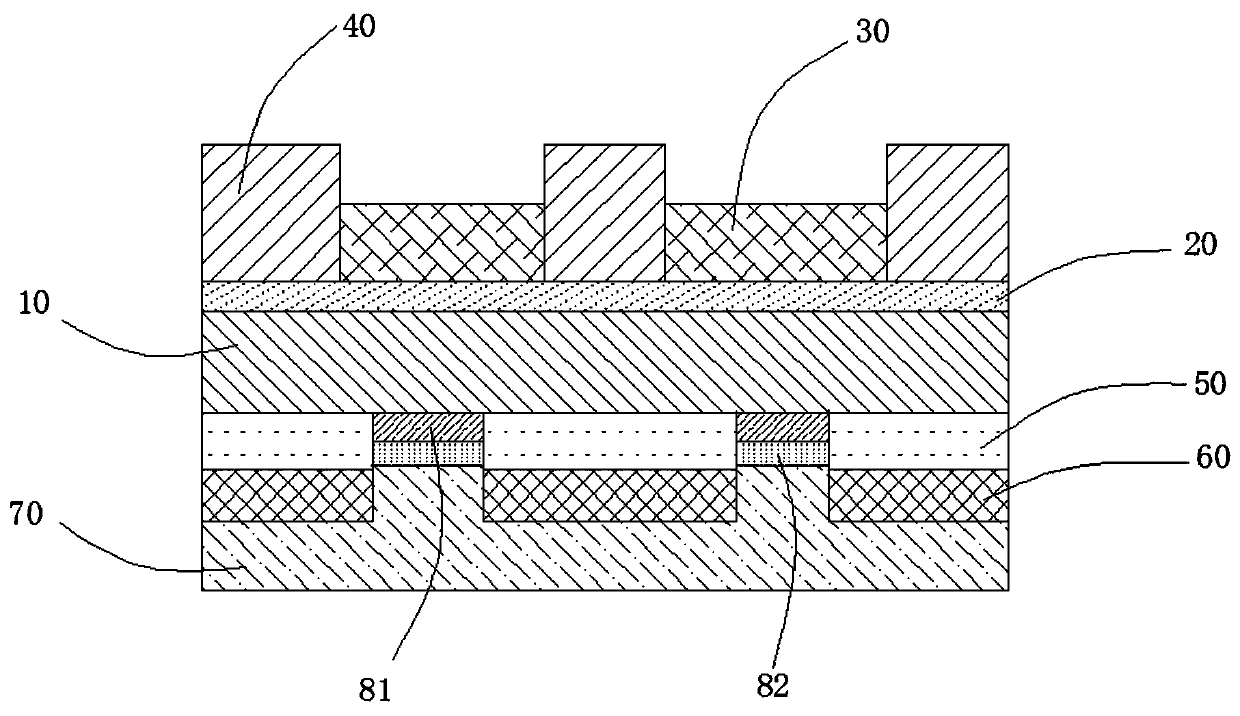

[0069] Such as figure 2 As shown, this embodiment is a solar cell. The difference from Embodiment 1 is that the high work function semiconductor material layer in this embodiment is two layers, which are divided into a first high work function semiconductor material layer 81 and a second high work function semiconductor material layer. Two high work function semiconductor material layers 82, wherein the first first high work function semiconductor material layer 81 is 9nm-V 2 o 5 , the second high work function semiconductor material layer 82 is 3nm-WO 3 . The high work function semiconductor material layer in this embodiment is denoted as 9nm-V 2 o 5 / 3nm-WO 3 , other parts are the same as in Example 1.

Embodiment 3

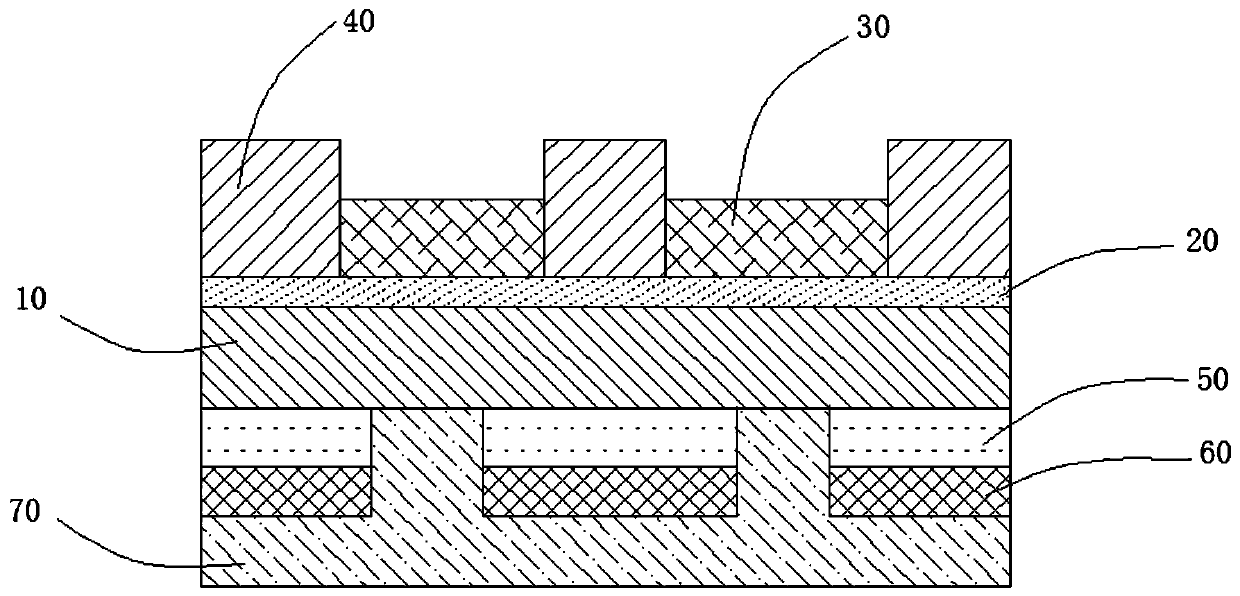

[0071] This embodiment is a solar cell. Compared with Embodiment 2, the difference lies in that the high work function semiconductor material layer is different. The high work function semiconductor material layer in this embodiment is 9nm-V 2 o 5 / 6nm-WO 3 , other parts are identical with embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electron work function | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com