motor

A motor and stator iron core technology, applied in the field of motors, can solve the problems of increasing efficiency, reducing coiling workability, reducing filling factor, etc., and achieving the effects of reducing copper loss, increasing efficiency, and saving manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

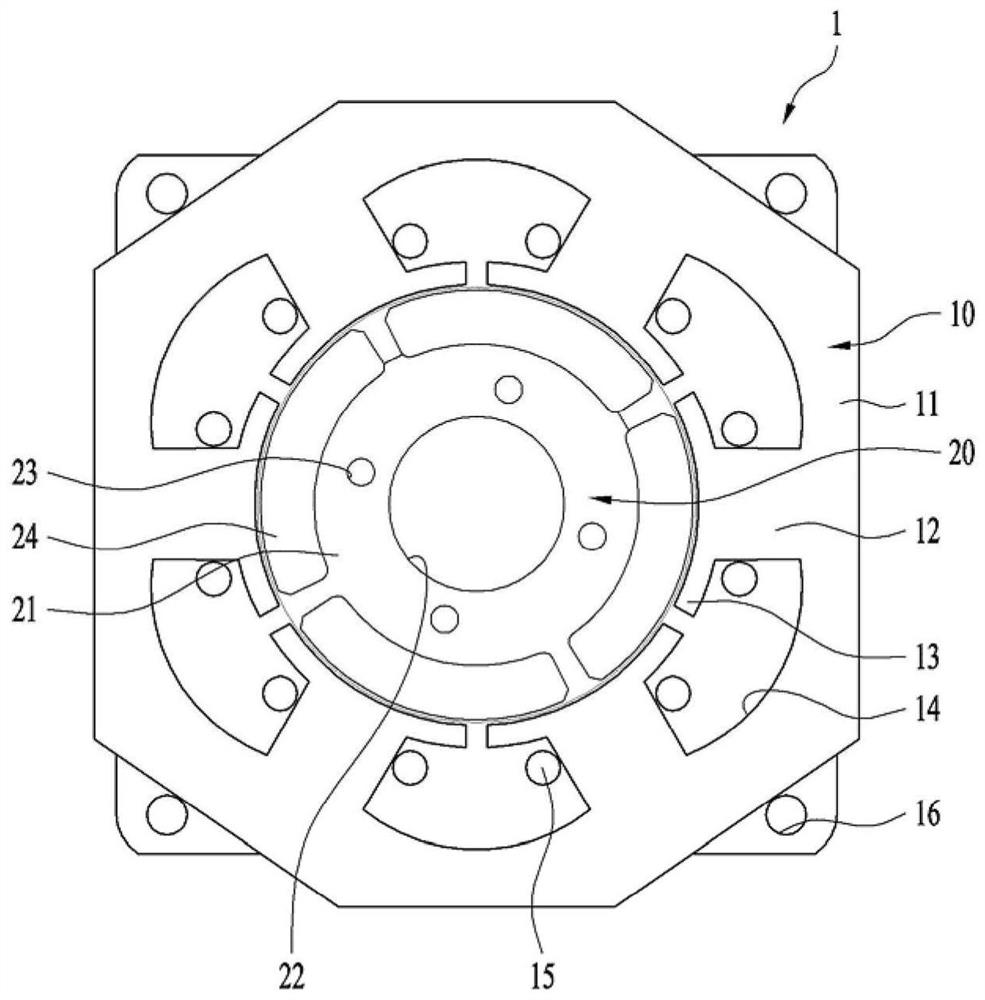

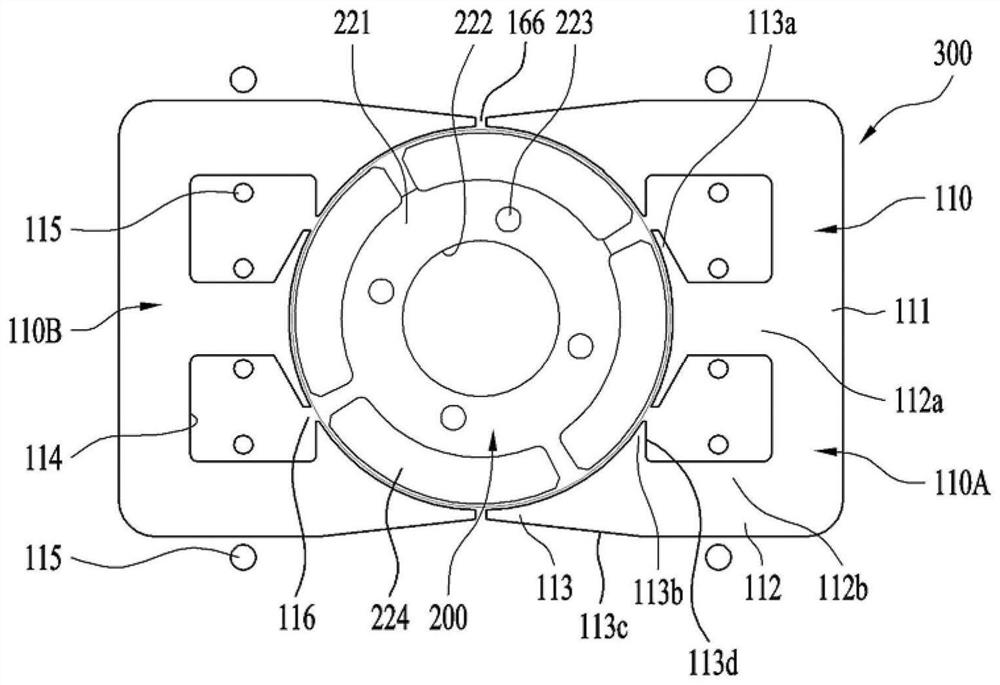

[0077] figure 2 A schematic plan view of a motor according to an embodiment of the present invention is shown.

[0078] The motor 300 may be composed of a stator 100 and a rotor 200 .

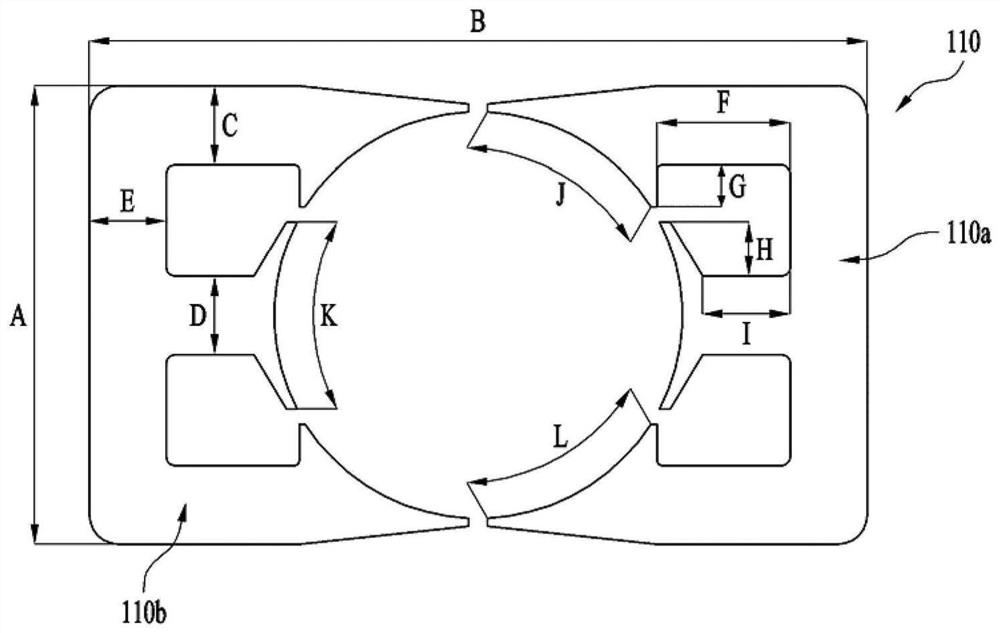

[0079] The stator 100 may include a stator core 110 formed of a magnetic body, and the rotor 200 may include a rotor core 221 formed of a magnetic body.

[0080] The stator core 110 and the rotor core 221 form a path through which magnetic flux moves, and may be formed by laminating electrical steel sheets in order to reduce core copper loss.

[0081] A shaft hole 222 and a coupling hole 223 may be formed in the rotor core 221 , and a plurality of permanent magnets 224 may be provided. therefore, figure 2 The rotor shown can be used with figure 1 The rotors shown are the same. However, as described below, various types of rotors can be applied to ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap