Light-weight refractory material and preparation method thereof

A refractory material and lightweight technology, applied in the field of refractory materials, can solve problems such as affecting the thermal insulation effect, human and environmental pollution, and wall breaking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

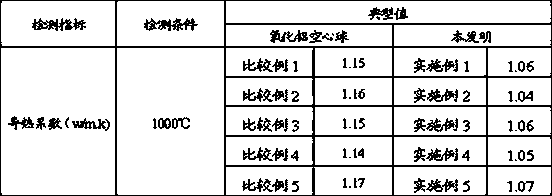

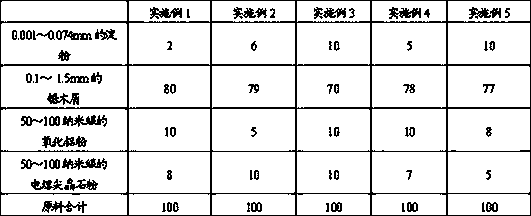

[0016] Lightweight refractory materials include: 0.001-0.074mm starch 2%; 0.1-1.5mm sawdust 80%; 50-100 nanometer alumina powder 10%; 50-100 nanometer fused spinel powder 8% , as shown in Table 1 below.

[0017] Mix the ingredients according to the proportions of the above components, and stir them evenly in the mixer, then add water at a ratio of 100-120 kg of water per 1000 kg of the mixture, and stir again; transfer the stirred material after adding water into the The granulator is granulated to obtain spherical granules with a particle diameter of 0.5-5 mm; the obtained spherical granules are baked at a temperature of 90-120 degrees for 20-30 hours to remove moisture, and the finished product can be obtained.

[0018] The lightweight refractory material obtained by using the above-mentioned ingredients and process was tested for thermal conductivity at 1000°C and found that the thermal conductivity was 1.06 (w / m.k), which was 1.15 ( w / m.k)) is significantly lower than tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com