Main shaft for large flow electromagnetic valve type injector

A technology of solenoid valves and injectors, which is applied in the direction of fuel injection devices, machines/engines, engine components, etc., can solve the problems affecting the stability and repeatability of the dynamic flow rate of injectors, and the difficulty of effectively increasing the flow rate, so as to improve the dynamic flow rate Stability and repeatability, easy promotion and use, and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

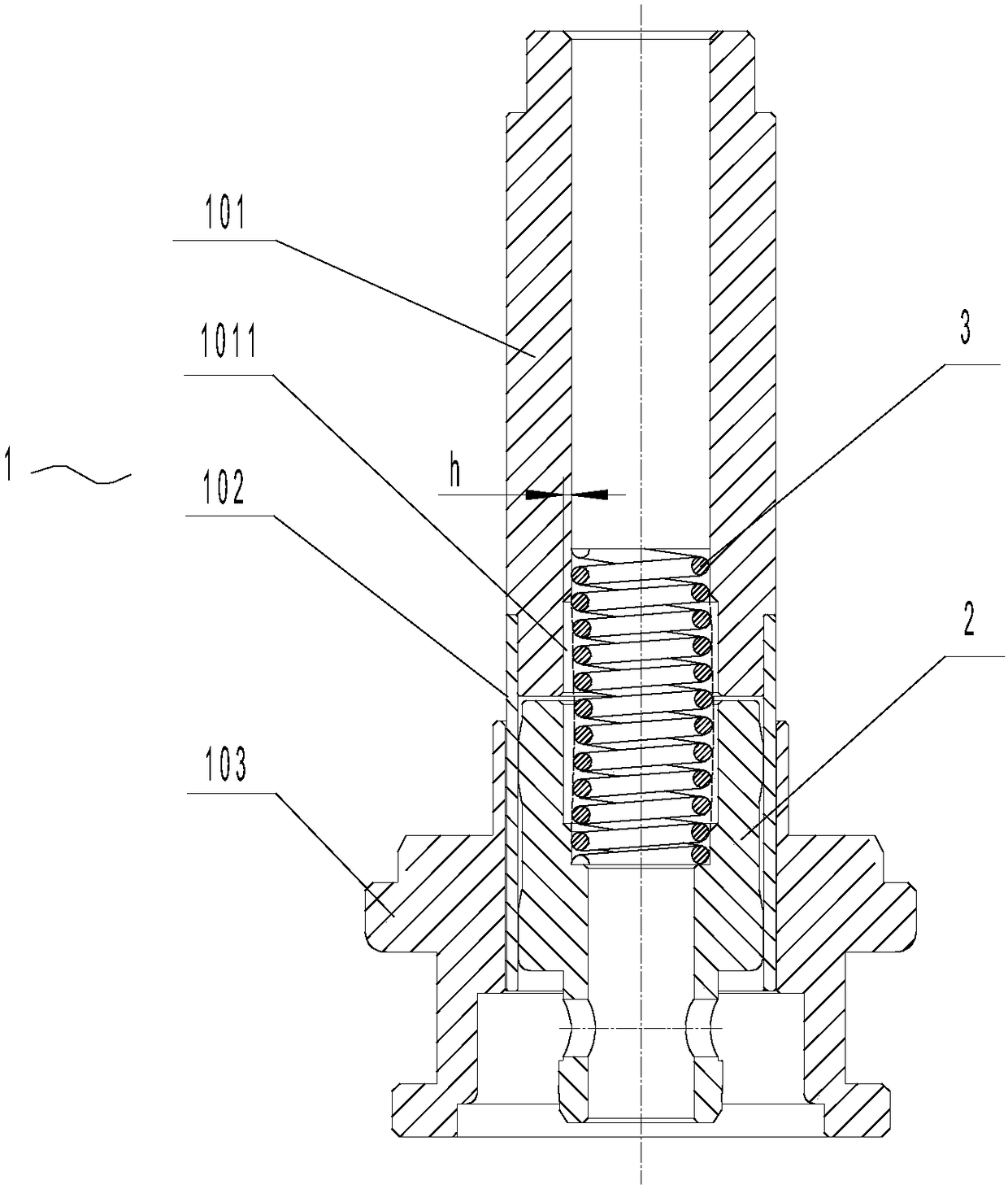

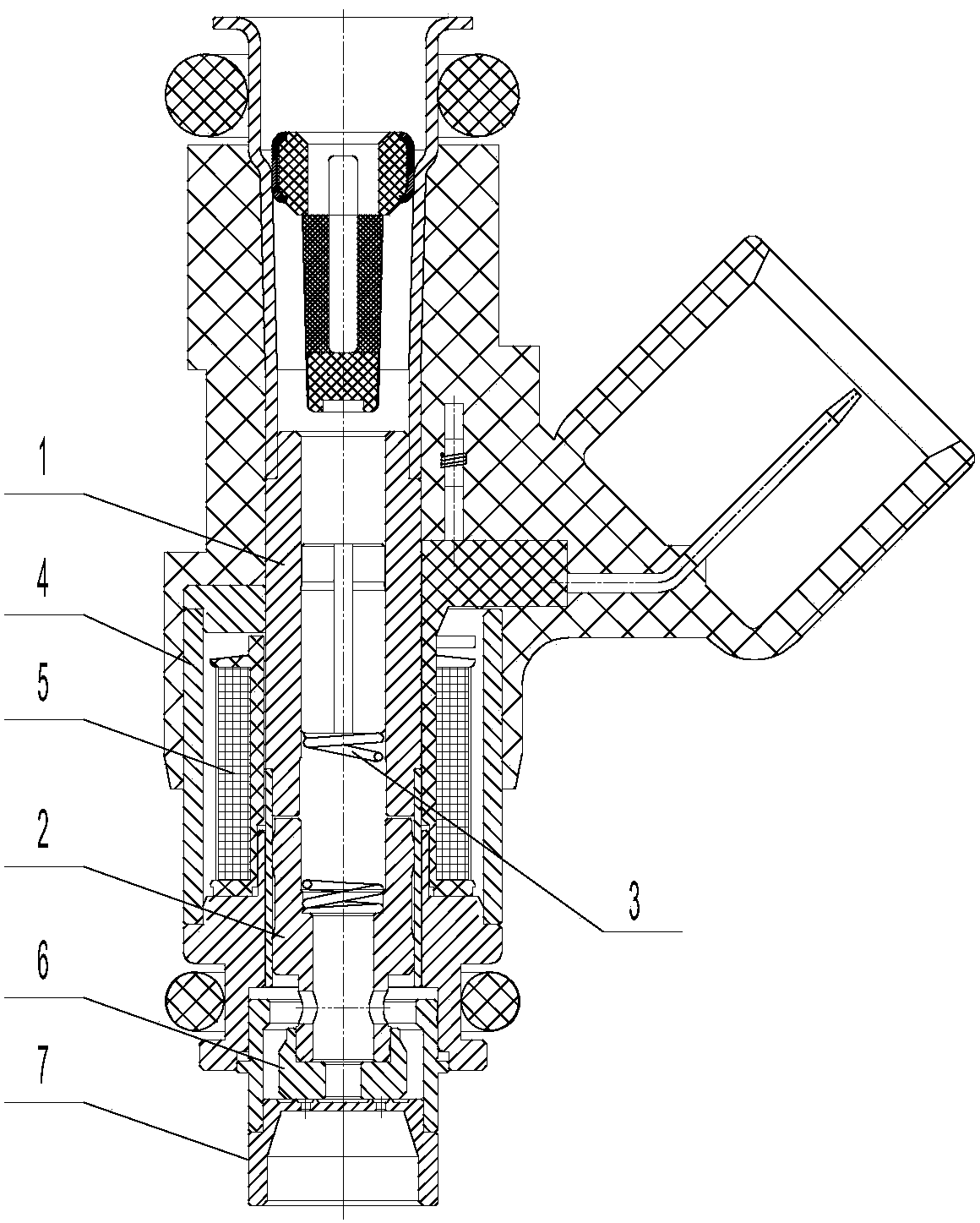

[0028] A spindle for a high flow solenoid injector (see figure 1 ), the main shaft is a split main shaft 1, which includes a main shaft body 101, a magnetic isolation sleeve 102, and an auxiliary shaft 103, wherein:

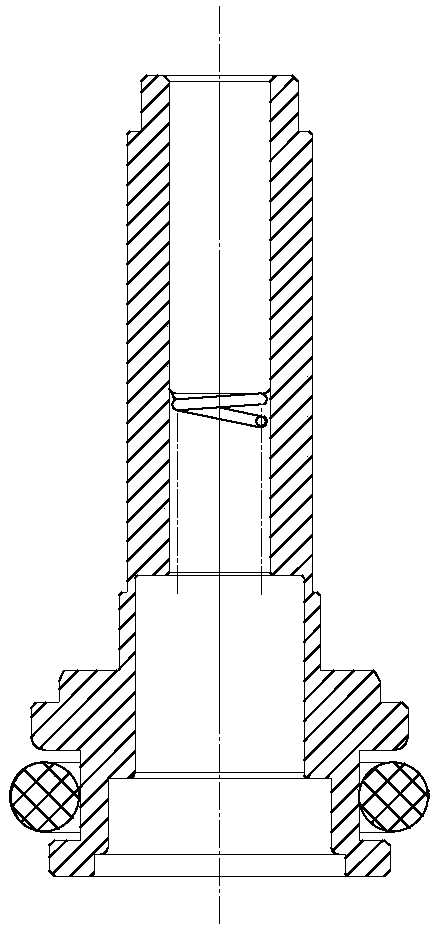

[0029] The main shaft body 101 is a tubular body structure, the main shaft body 101 is made of low magnetic resistance material, the upper end of the main shaft body 101 is connected with the oil inlet nozzle, the lower end of the main shaft body 101 is connected with the magnetic isolation sleeve 102, the main shaft body 101 A return spring 3 is installed in the center hole, and the center hole wall of the main shaft body 101 is provided with an annular spring relief groove 1011 at the position corresponding to the installation of the return spring 3, and the groove depth of the spring relief groove 1011 is h=0.2mm .

[0030] The magnetic isolation sleeve 102 is made of high magnetic resistance material, the valve core 2 is installed inside the magnetic isolati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Groove depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com