Multi-loop self-lubricating gear pump for numerical control machine tool

A technology of CNC machine tools and gear pumps, which is used in lubrication pumps, engine lubrication, pumps, etc., can solve the problems of insufficient lubricating oil filling, low lubrication degree of guide rails, different pressures, etc. Increase the effect of traffic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: Please refer to Figure 1-Figure 6 , The specific embodiments of the present invention are as follows:

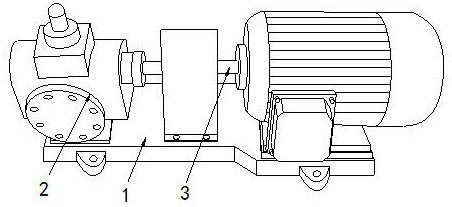

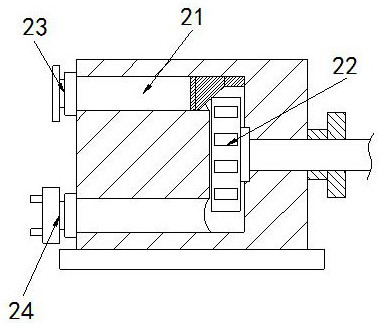

[0027] The structure includes a chassis 1, a gear pump 2, and a power shaft 3. The top of the chassis 1 is welded with a gear pump 2. The power shaft 3 is installed at the rear end of the gear pump 2, and the gear pump 2 includes a flow groove 21, The gear 22, the oil inlet 23, and the oil outlet 24. The circulation groove 21 is U-shaped and is located in the middle of the gear pump 2. The gear 22 is connected to the end of the power shaft 3 and is located in the circulation groove At the rear end of 21, the oil inlet 23 is arranged at the upper port of the circulation groove 21, and the oil outlet 24 is arranged at the lower port of the circulation groove 21.

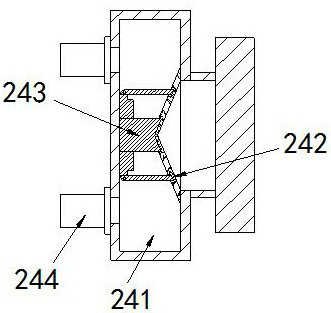

[0028] The oil outlet 24 includes an oil collecting groove 241, an oil passing plate 242, an adjusting device 243, and a diversion hole 244. The oil collecting groove 241 is arranged in the middle of th...

Embodiment 2

[0033] Example 2: Please refer to Figure 7-Figure 8 , The specific embodiments of the present invention are as follows:

[0034] The oil baffle a34 includes a gear shaft c1, a flow guide groove c2, a return block c3, and a contact block c4. The gear shaft c1 is arranged at the rear end of the oil baffle a34, and the flow guide groove c2 is provided with two, And is located at the bottom of the oil baffle a34, the return block c3 is provided with more than ten, and they are distributed across the upper end of the diversion groove c2, the contact block c4 is arranged at the front end of the oil baffle a34, the diversion groove c2 is arc-shaped, and the port at the back end is larger than the port at the front end, which is conducive to allowing the lubricating oil to circulate in one direction and speeding up the flow of lubricating oil.

[0035] The contact block c4 includes a rewind spring c41, a rubber head c42, and a bump c43. The rewind spring c41 is nested on the side end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com