Saw dust powder collecting material bin structure

A wood powder and silo technology, applied in the field of collecting silos, can solve the problems of being unsuitable for board making, time-consuming and labor-intensive, etc., and achieve the effects of meeting the requirements of use, increasing transportation volume, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

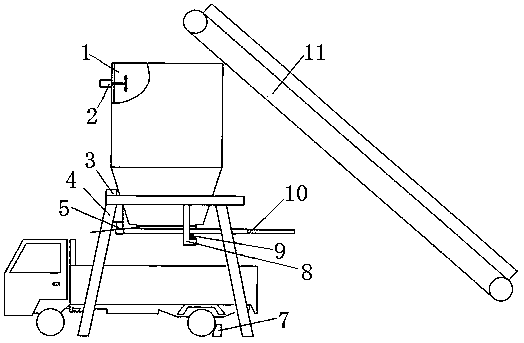

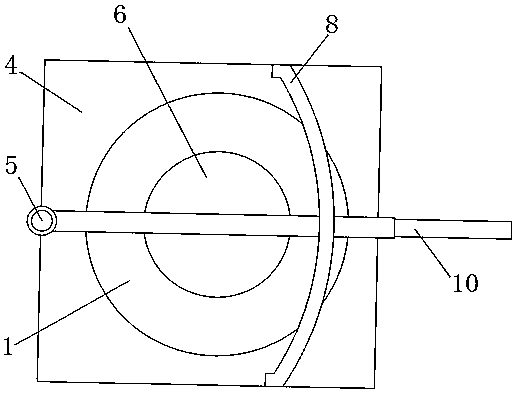

[0009] This technical solution describes the embodiment in detail in conjunction with the above drawings. A rotary level gauge 2 is installed on the side close to the upper part of the silo 1. When the sawdust powder in the silo hinders the rotation of the rotary level gauge, an electrical signal is output. For the alarm, the electrical signal is received by the input terminal of the alarm 3, and the buzzer in the alarm starts to alarm, prompting the staff to unload the material, the rotary material level gauge is electrically connected with the alarm, and the alarm is installed on the material On the bracket at the lower part of the silo, the opening end of the head of the silo is connected with a trough conveyor belt, the other end of the trough conveyor belt 11 is connected with the powder sieving machine, the silo is fixed on the bracket, and the bracket 4 is supported by the support 4. The leg support is a portal frame, and the width of the portal frame is subject to the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com