Balance shaft of three-cylinder engine

A technology of balance shaft and engine, which is applied in the direction of mechanical equipment, vibration suppression adjustment, spring/shock absorber, etc. It can solve the problems of increasing the vibration of the three-cylinder engine, heavy weight, and the cost increase of the engine and the whole vehicle, so as to reduce vibration , the effect of improving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

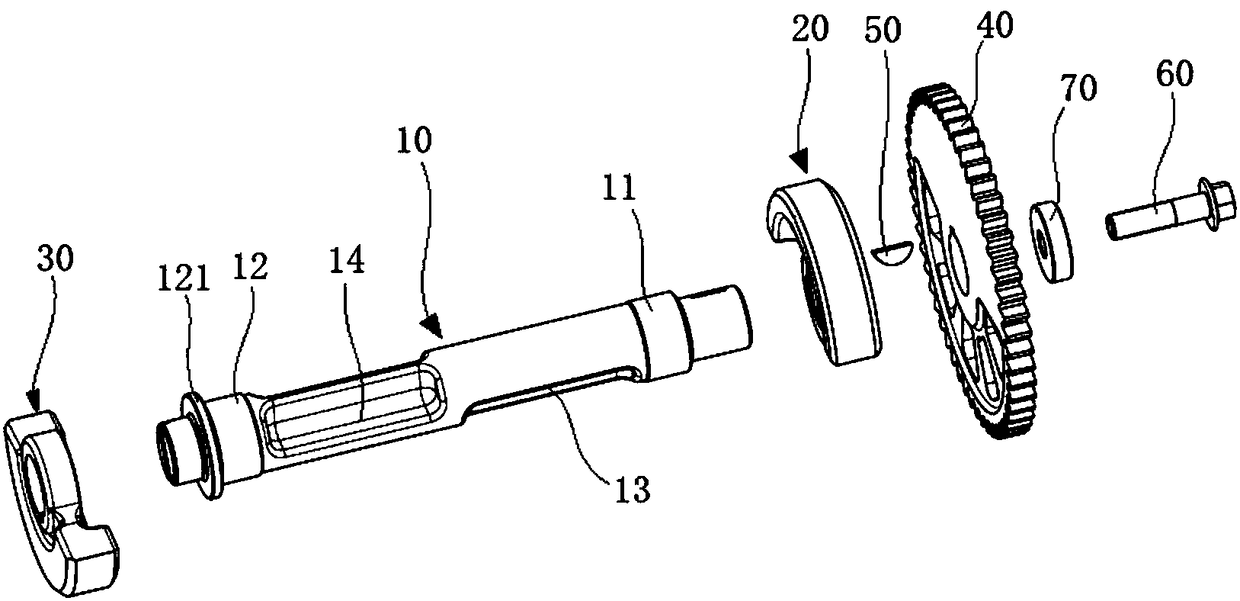

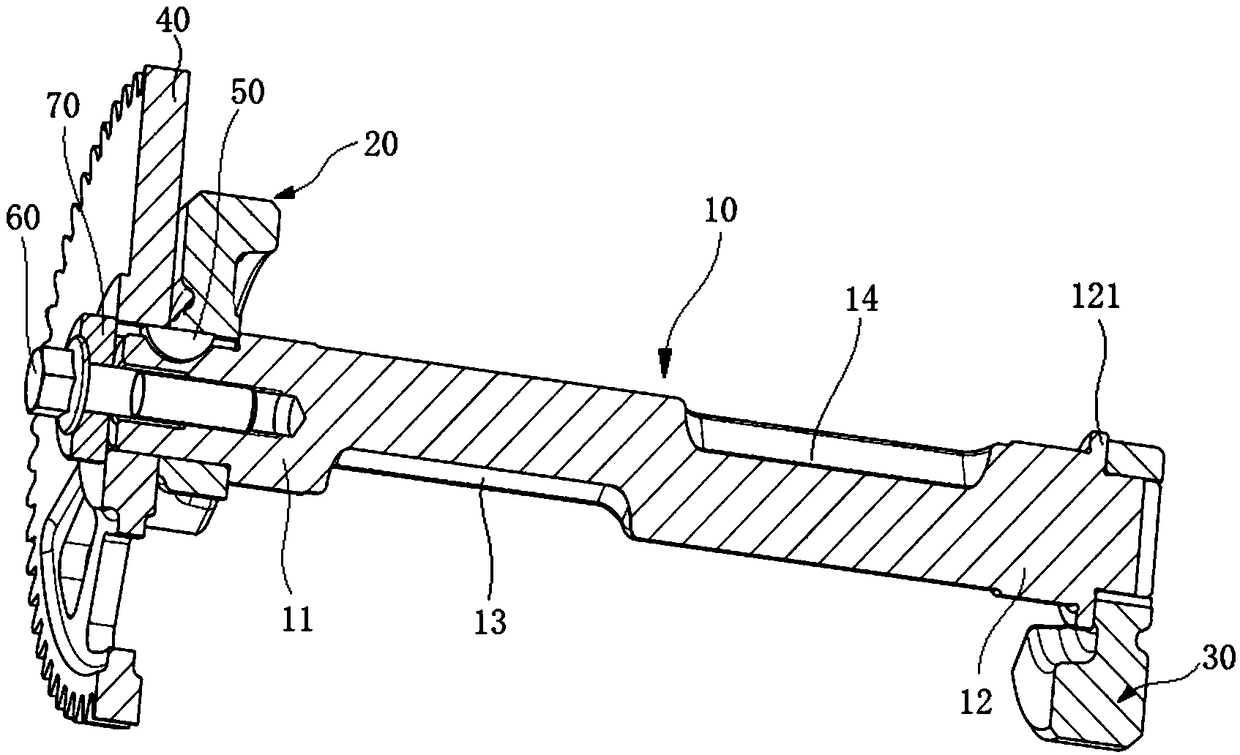

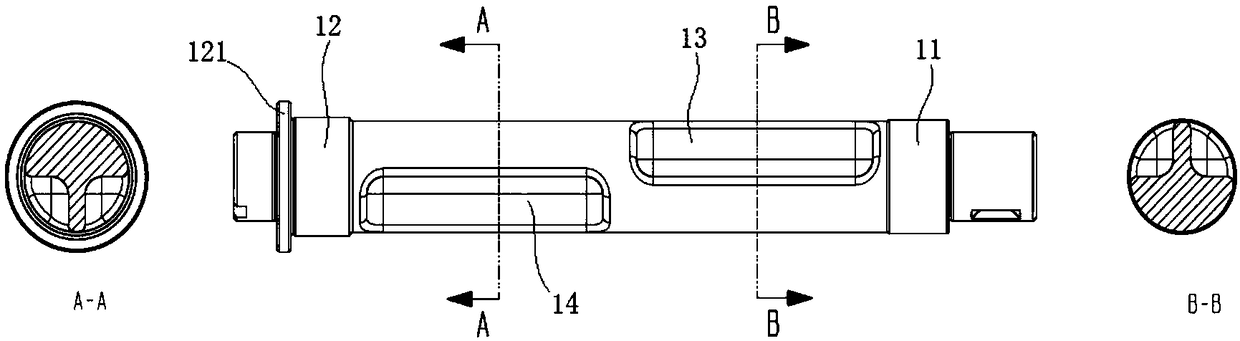

[0011] combined with Figure 1~4 The present invention will be described in detail.

[0012] A three-cylinder engine balance shaft, comprising a balance shaft 10, a front balance weight 20 installed at the front end of the balance shaft 10, a rear balance weight 30 installed at the rear end of the balance shaft, and a balance shaft drive gear 40, the rear balance weight 30 Set on the rear end of the rear journal 12 of the balance shaft 10, the front balance weight 20 and the balance shaft drive gear 40 are sequentially connected to the front end of the front journal 11 of the balance shaft 10 by the key 50, and the mass of the rear balance weight 30 is greater than that of the front balance shaft. The mass of the weight 20, the eccentric arrangement directions of the front balance weight 20 and the rear balance weight 30 are opposite. The balance shaft 10, the front balance weight 20, the rear balance weight 30 and the balance shaft drive gear 40 form a balance system, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com