Stirring rod rotation speed monitoring device and method

A technology of monitoring device and stirring rod, which is applied in the direction of the device used to measure the time required to move a certain distance, can solve the problems of inaccurate measurement of the rotating speed of the stirring rod, affecting product quality, etc., to avoid manual measurement errors, reduce quality fluctuations, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific embodiments of the present disclosure will be described in detail below with reference to the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present disclosure, and are not used to limit the present disclosure.

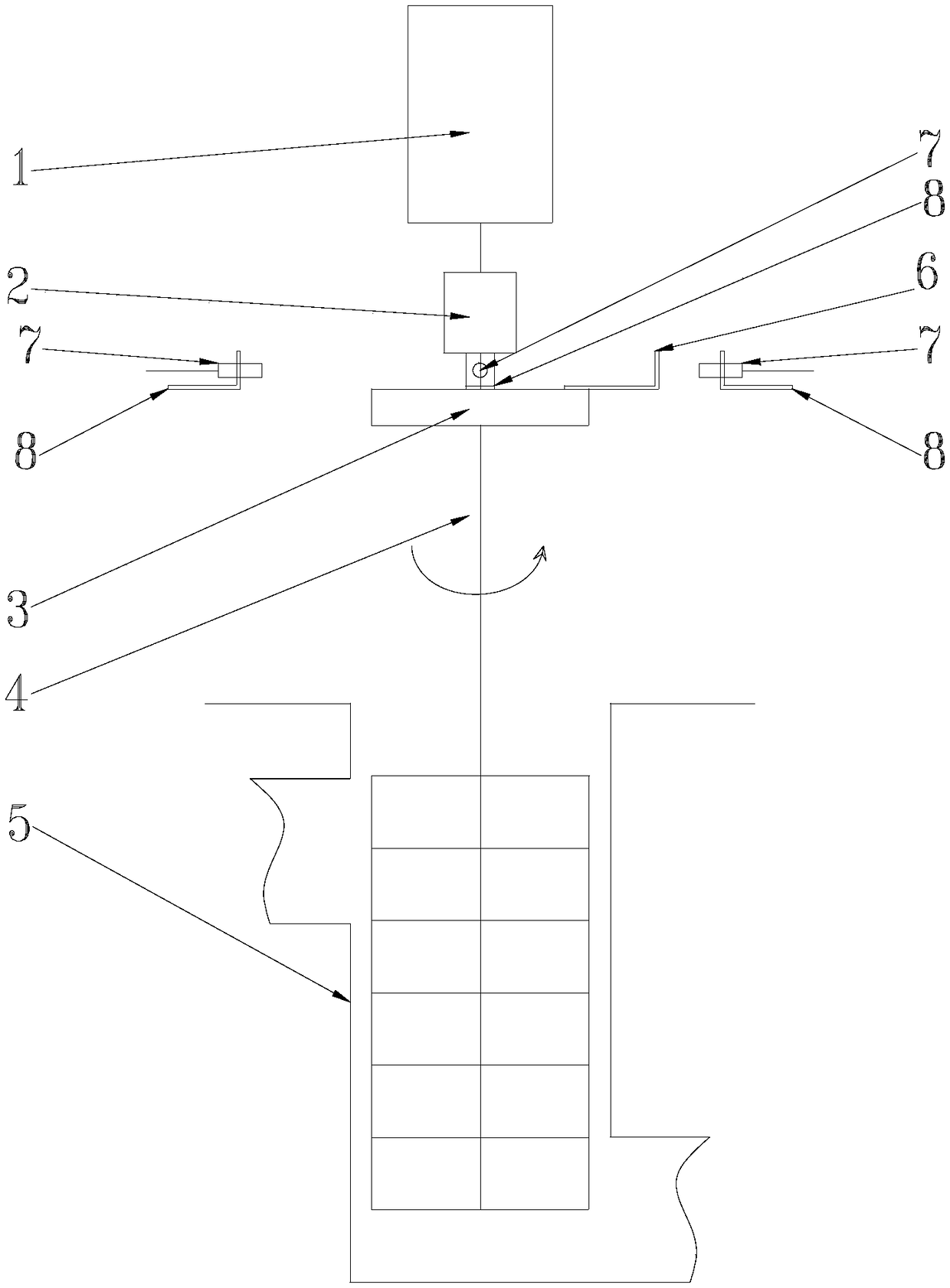

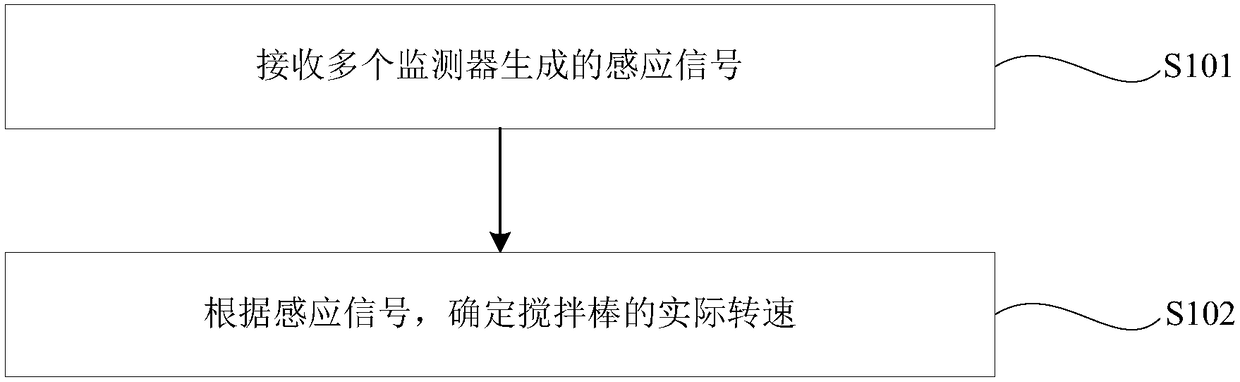

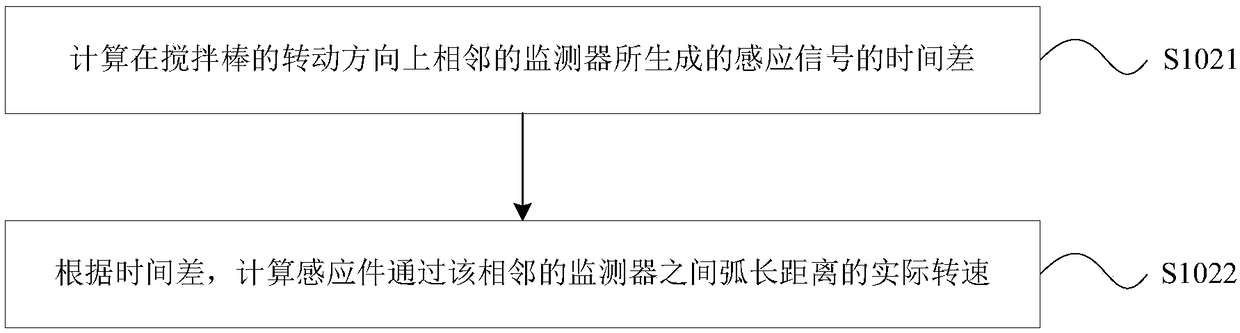

[0038] The first aspect of the present disclosure: a device for monitoring the rotation speed of a stirring rod is provided, with reference to figure 1 . The device includes: a sensing element 6 mounted on the stirring rod 4, and a plurality of monitors 7 arranged at an angle along the circumferential direction with the stirring rod 4 as the center, and the sensing element 6 can pass through multiple monitors in turn when the stirring rod 4 rotates. Each monitor 7 can generate a sensing signal when the sensing element 6 passes through its monitoring area. The monitor 7 is electrically connected to the controller. The controller is used to determine the sensing sig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com