Surface modified titanium dioxide preparation method and surface modification equipment thereof

A surface modification, titanium dioxide technology, applied in chemical instruments and methods, titanium dioxide, titanium compounds, etc., can solve the problems of low dispersibility, slow hydrolysis rate, complicated control conditions, etc., and achieve the effect of excellent quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

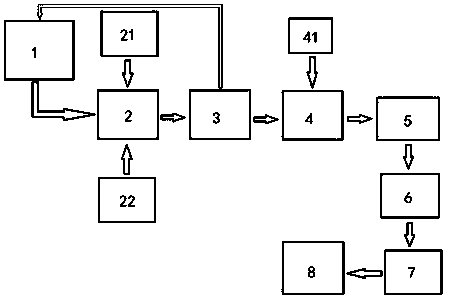

Image

Examples

specific Embodiment 1

[0025] A kind of preparation method of surface modified titanium dioxide, its concrete steps are as follows:

[0026] Step 1, the titanyl sulfate solution of 180g / L~210g / L (with TiO 2 Calculation) and K at a concentration of 20g / L 3 PO 4 solution, respectively heated to 70°C, and according to the volume ratio of 15:1, the titanyl sulfate solution was slowly added to K 3 PO 4 Neutralize in the solution, and control the flow rate to ensure that the reaction time is controlled within 10 minutes;

[0027] Step 2, add SiO at the same time 2 +MgO equal ratio of additional seeds; its SiO 2 +MgO is a suspension of nanoparticles, and its concentration is 0.3g / L; the amount added is according to the ratio of titanyl sulfate solution volume ratio of 120:1;

[0028] Step 3: After the neutralization reaction, the temperature of the solution is raised to 90°C; the stability of the seed crystal is determined to be 100-130°C, and the seed crystal is quickly put into the preheated hydrol...

specific Embodiment 2

[0030] A preparation method of surface modified titanium dioxide, the main steps are the same as in Example 1, wherein K 3 PO 4 The concentration of the solution is 17g / L; SiO 2 +MgO suspension concentration is 0.25g / L. After the neutralization reaction, the hydrolysis of the titanium solution can obtain crystallization centers with uniform particle size, so that the particle size and particle size distribution of the final product titanium dioxide are uniform, and the final titanium dioxide has excellent quality.

specific Embodiment 3

[0031] A kind of preparation method of surface modified titanium dioxide, its concrete steps are as follows:

[0032] Step 1, the titanyl sulfate solution of 180g / L~210g / L (with TiO 2 Calculation) and K at a concentration of 15g / L 3 PO 4 solution, respectively heated to 75°C, and according to the volume ratio of 12:1, the titanyl sulfate solution was slowly added to K 3 PO 4 Neutralize in the solution, and control the flow rate to ensure that the reaction time is controlled at 12 minutes;

[0033] Step 2, add SiO at the same time 2 +MgO equal ratio of additional seeds; its SiO 2 +MgO is a suspension of nanoparticles, and its concentration is 0.2g / L; the amount added is according to the ratio of titanyl sulfate solution volume ratio 110:1;

[0034] Step 3: After the neutralization reaction, the temperature of the solution is raised to 95°C; the stability of the seed crystal is determined to be 100-130, and the seed crystal is quickly put into the preheated hydrolyzed tita...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com