A method of controlling the coaxiality of cathode and anode of magnetron with positioning ceramic ring

A technology of magnetron and coaxiality, applied in magnetrons, discharge tubes, time-of-flight electron tubes, etc., can solve the problem of lower working voltage of the whole tube, poor batch production consistency, and difficulty in accurately ensuring the coaxiality of cathode and anode Degree and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

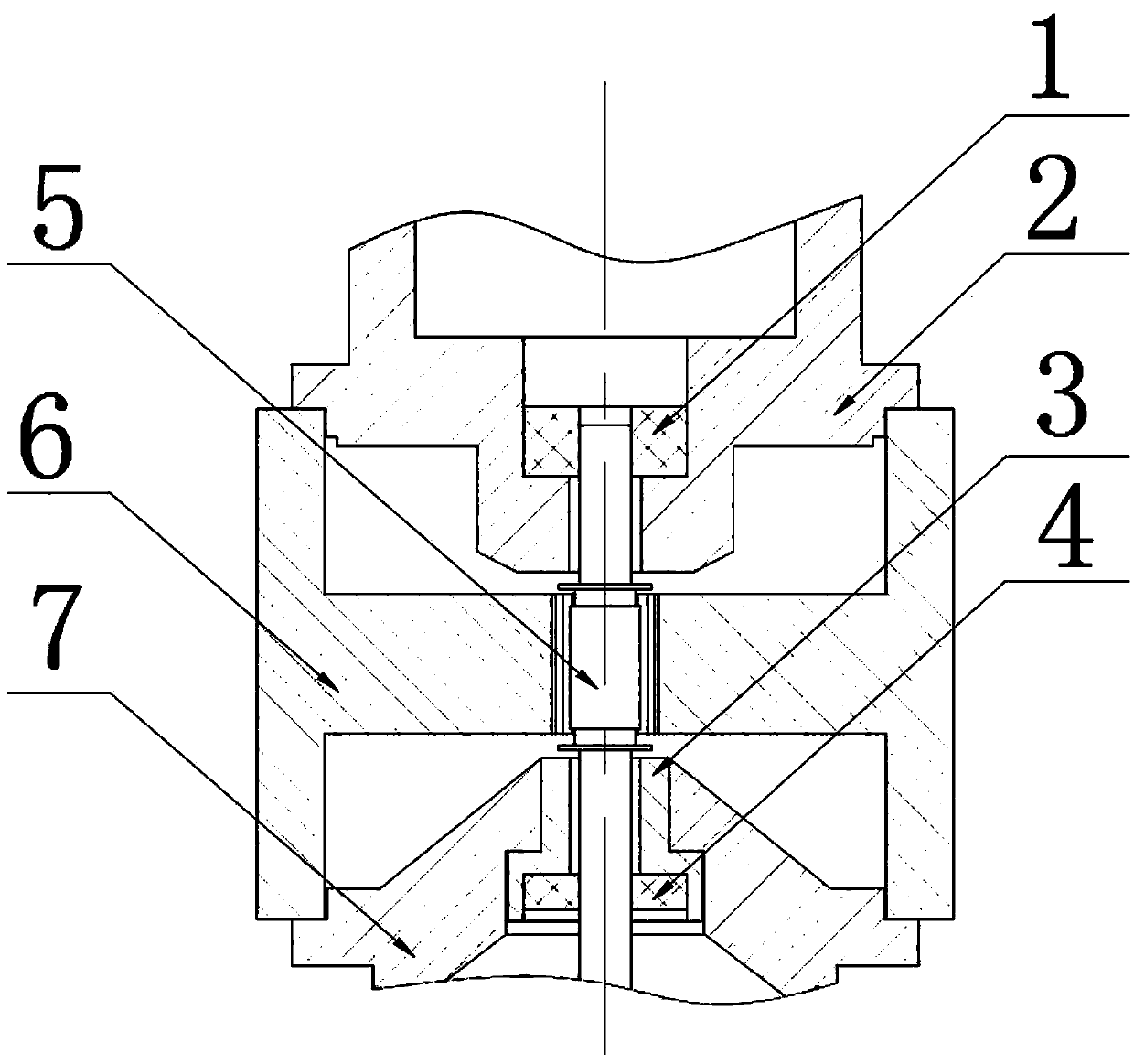

[0018] A method for controlling the coaxiality of the anode and cathode of a magnetron by using a positioning ceramic ring, using a ceramic ring with the coaxial positioning of the cathode and anode, the ceramic ring and the cathode are fixed in the tube core, and the cathode and anode can always be guaranteed no matter in any state The coaxiality meets the requirements, which is achieved through the following steps:

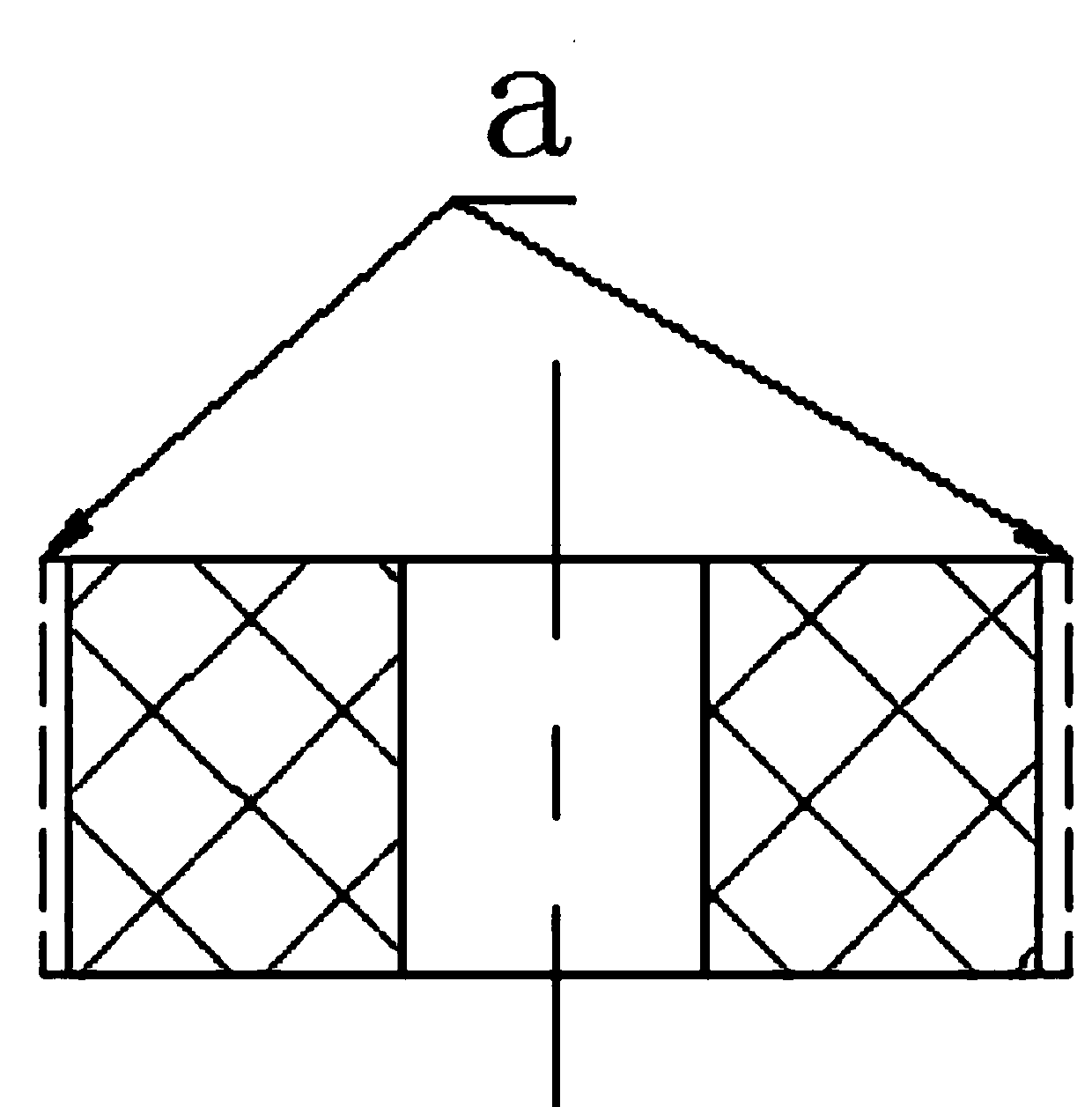

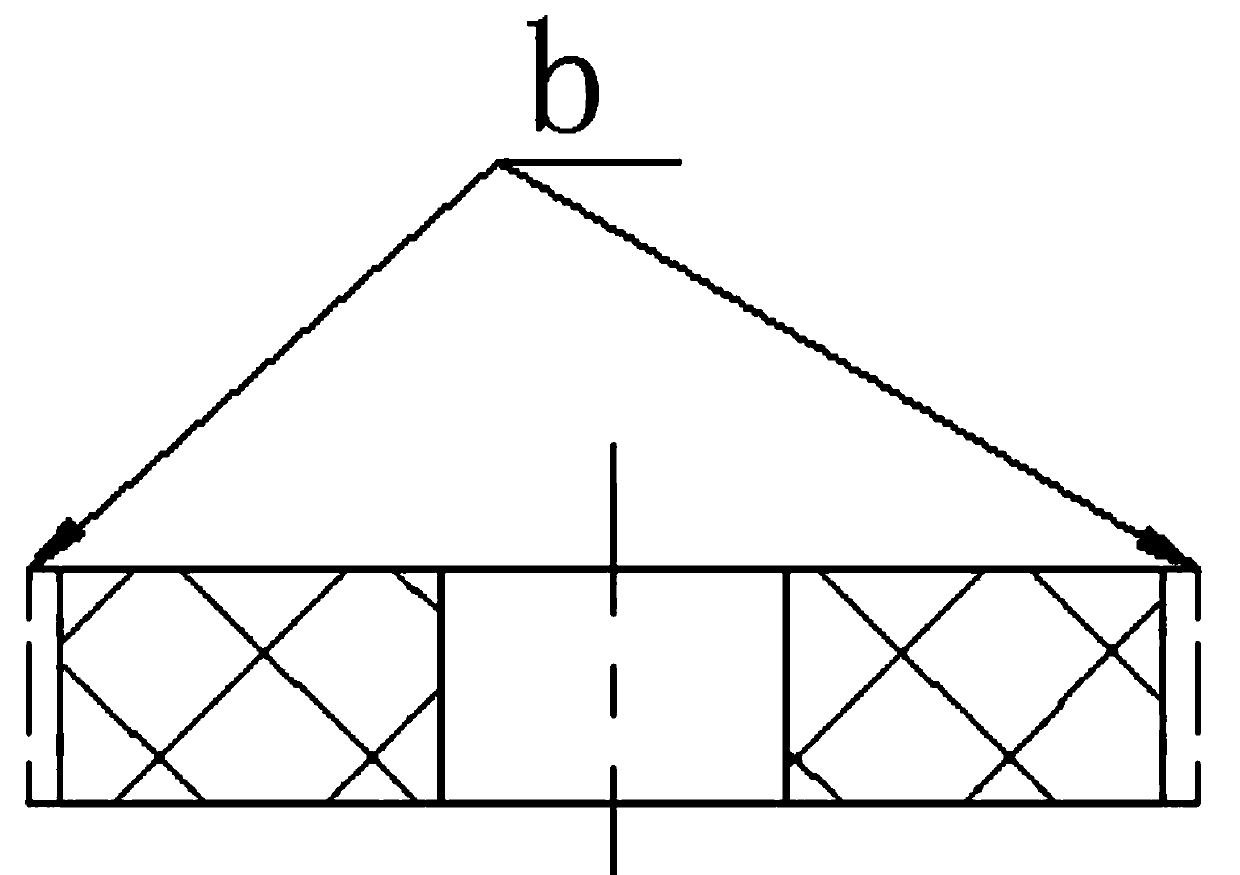

[0019] Step (1). Use Al 2 o 3 The ceramic ring is formed by powder pressing and sintered at high temperature, and then the upper coaxial positioning ceramic ring 1 (such as figure 1 shown) and the lower coaxial positioning ceramic ring 4 (such as figure 2 As shown), the coaxiality of the positioning ceramic ring is a necessary condition to ensure the coaxiality of the cathode and anode of the magnetron. Therefore, it is necessary to ensure that the coaxiality of the positioning ceramic ring meets the requirements during processing;

[0020] Step (2). After m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com