Liquid-cooling system

A cooling water system and liquid cooling technology, applied in the direction of cooling/ventilation/heating transformation, electrical components, electrical equipment structural parts, etc., can solve the problems of uneven cooling, insignificant energy saving effect, and incapable of intelligent distribution in data centers, etc. Achieve the effect of saving energy consumption, realizing stable operation and ensuring normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] Embodiment: a liquid cooling system.

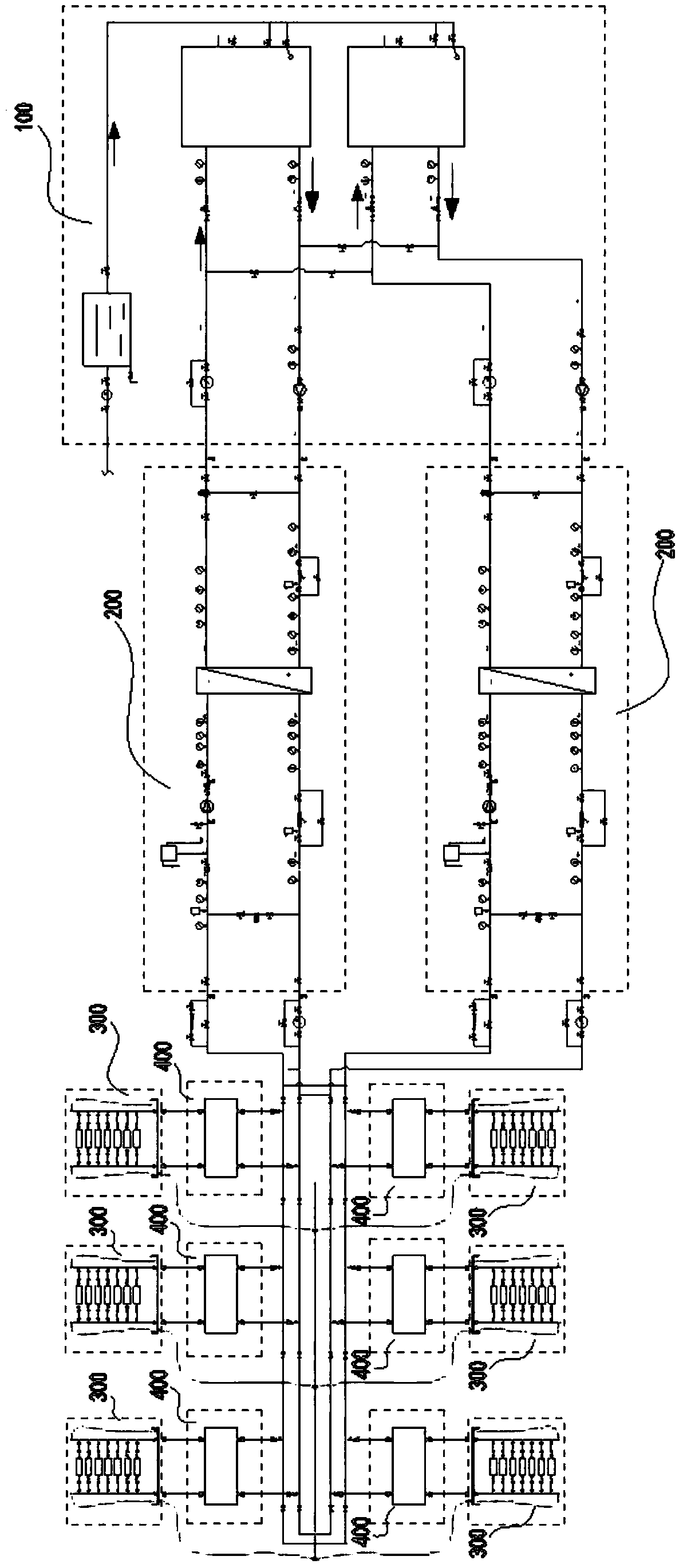

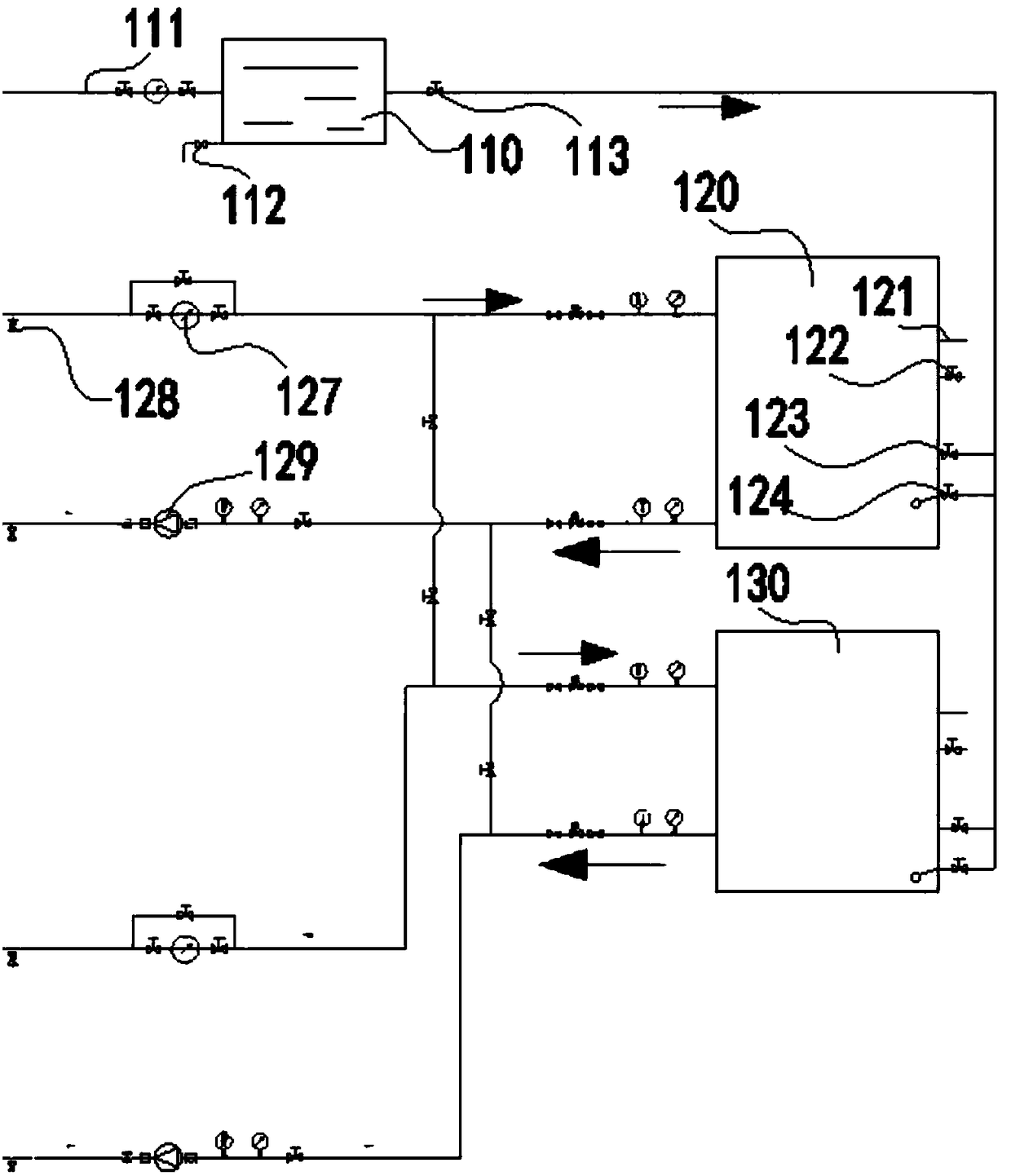

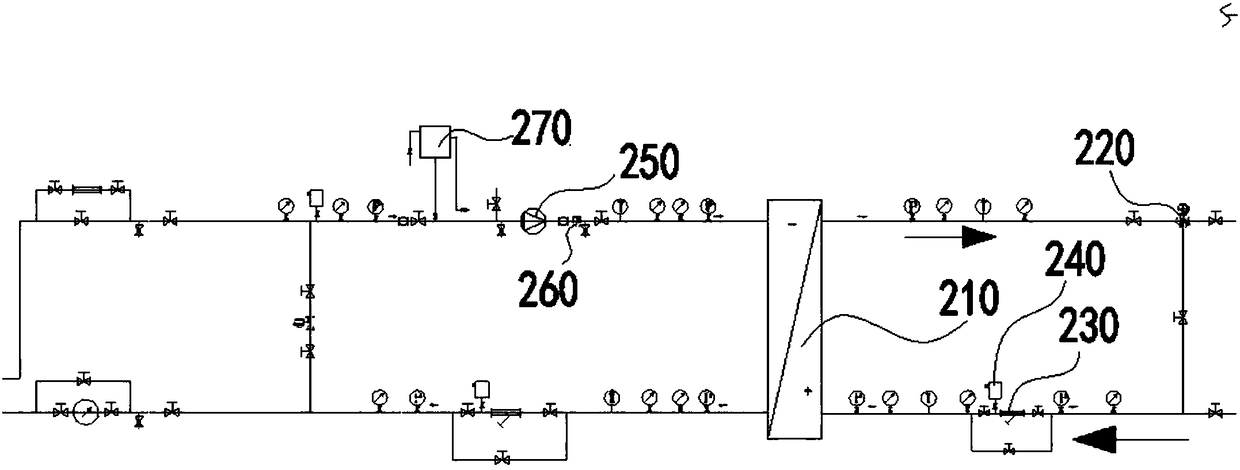

[0029] refer to Figure 1 to Figure 6 As shown, a liquid cooling system includes: an external circulating cooling water system 100, the external circulating cooling water system 100 includes an emergency make-up water tank 110, a first cooling tower 120 and a second cooling tower 130, the first cooling tower 120 and the second cooling tower 130 have the same structure, and the first cooling tower 120 and the second cooling tower 130 are provided with quick replenishment pipes 123 and automatic replenishment pipes 124, and the water outlets of the emergency replenishment tank 110 pass through pipes respectively The fast water supply pipe 123 and the automatic water supply pipe 124 connected to the first cooling tower 120 and the second cooling tower 130, between the liquid outlet pipe of the first cooling tower 120 and the liquid outlet pipe of the second cooling tower 130 and the first cooling The liquid inlet pipe of the tower 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com