Method and system for automatically conveying packages, robot and storage device

An automatic conveying and robotic technology, applied in the field of robotics, can solve the problems of high labor cost for conveying and sorting, high configuration cost, easy waste of resources, etc., and achieve the effect of reducing manual participation, reducing labor cost and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

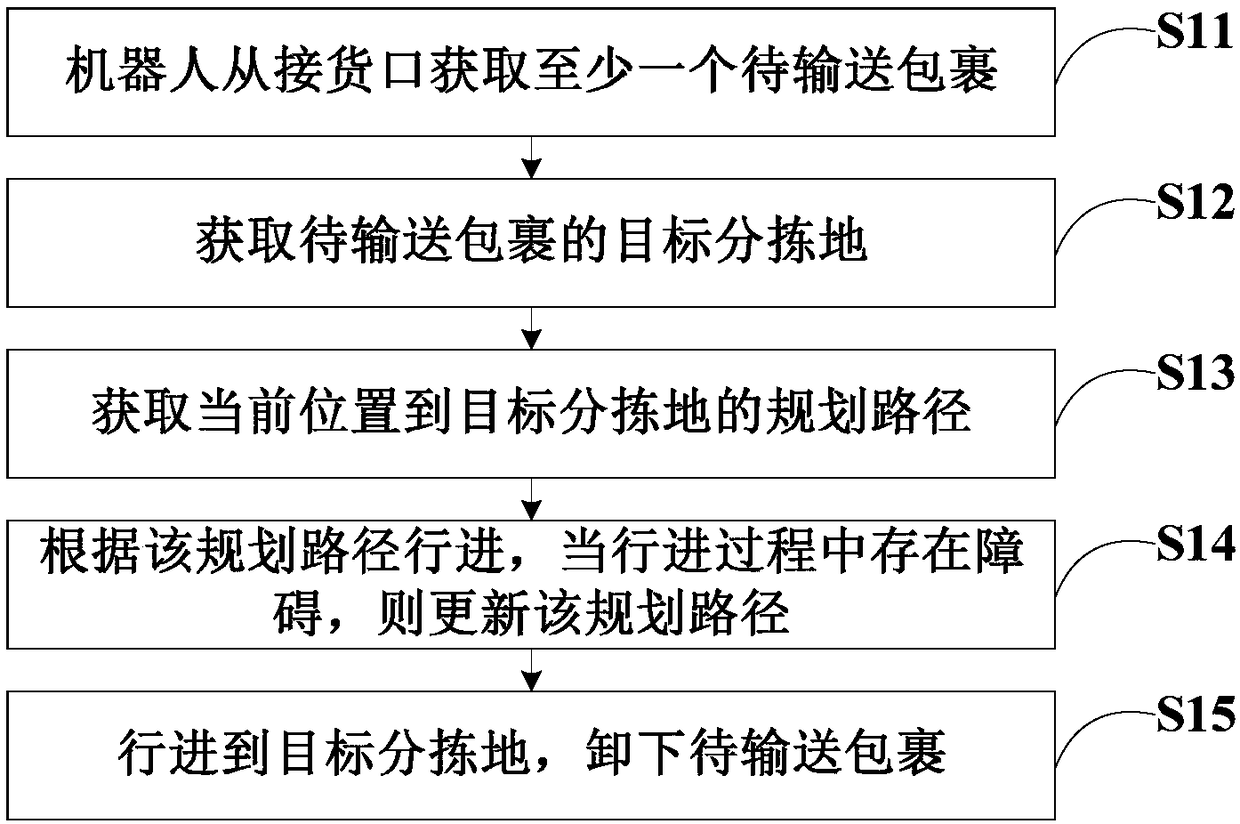

[0041] Such as figure 1 As shown, the first embodiment of the method for automatically delivering parcels of the present invention includes:

[0042] S11: The robot obtains at least one package to be delivered from the receiving port;

[0043] In this embodiment, at least one package to be transported by the robot has the same target sorting place, and the number depends on the specific situation, which is not specifically limited here.

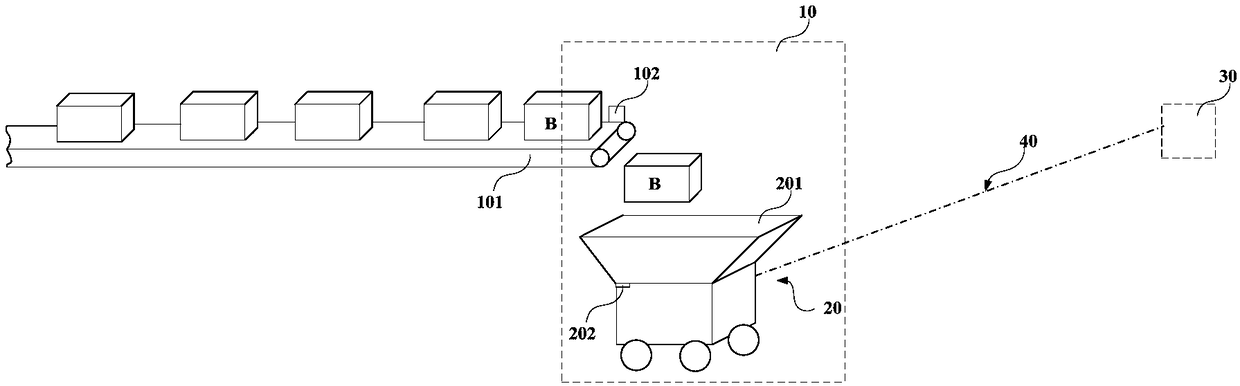

[0044] Specifically, combined with figure 2 As shown, in an application example, the robot 20 obtains at least one package B to be transported from the conveyor belt 101 arranged at the receiving port 10 . Among them, the robot 20 can obtain the number of packages B to be transported this time through the control center (not shown in the figure), for example, 2, these 2 packages B to be transported are continuously transmitted on the conveyor belt 101, and continuously enter the robot 20. On the storage mechanism 201 , the sensing device ...

Embodiment approach

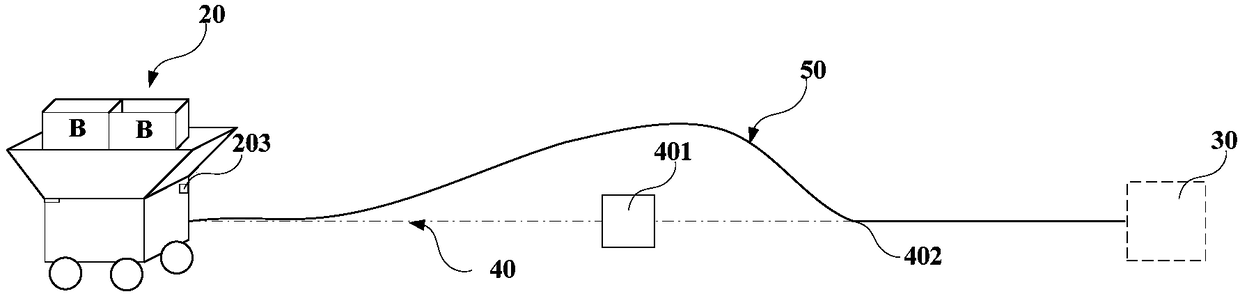

[0127] Specifically, combined with Figure 17 As shown, in an application example, the robot 20 receives an obstacle avoidance message sent by other robots 403, and the obstacle avoidance message includes the destination address 60 of the other robot 403, that is, the destination sorting place 60 of the package to be delivered, then the robot 20 Compare the priority A1 corresponding to the destination address 60 with its own destination address 30, that is, the target sorting place 30 of the package delivered by the robot 20, and compare the corresponding priority B1 to determine that the priority A1 is higher than the priority B1. That is to say, the priority corresponding to the destination address 60 of other robots 403 is higher than the priority corresponding to the destination address 30 of the robot 20, and the robot 20 updates its own planned path so that the updated planned path 50 avoids other robots, while other The robot can follow the original planned path. In on...

no. 1 example 21

[0149] Such as Figure 22 As shown, the first embodiment 21 of the robot of the present invention includes: at least one memory 211 and at least one processor 212 connected in communication with each other.

[0150] The processor 212 controls the operation of the robot 21, and the processor 212 may also be called a CPU (Central Processing Unit, central processing unit). The processor 212 may be an integrated circuit chip with signal processing capabilities. Processor 212 may also be a general purpose processor, digital signal processor (DSP), application specific integrated circuit (ASIC), off-the-shelf programmable gate array (FPGA) or other programmable logic device, discrete gate or transistor logic device, discrete hardware component . A general-purpose processor may be a microprocessor, or the processor may be any conventional processor, or the like.

[0151] The processor 212 is configured to execute instructions to implement the method provided by any one of the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com