Water-in-oil solid cream foundation and preparation method thereof

A technology of water-in-oil type and foundation cream, which is applied in the direction of pharmaceutical formulations, cosmetic preparations, dressing preparations, etc., and can solve the problems of not being able to provide product skin feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

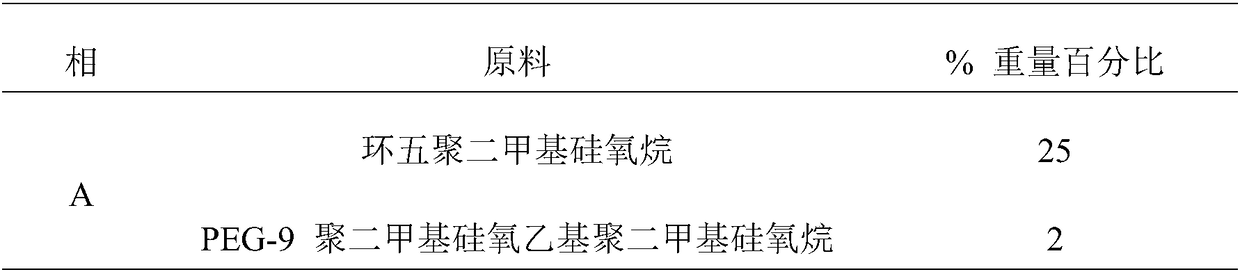

[0090] A water-in-oil type solid foundation cream, by weight percentage, its raw material components and contents are shown in the following table:

[0091] Table 1 composition and content of water-in-oil type solid foundation cream of the present invention

[0092]

[0093]

[0094] Preparation Process:

[0095] 1. Add the raw materials of phase B into the water phase pot one by one, stir and raise the temperature to 60-70°C, stir until the powder is fully dissolved and transparent, then cool down to room temperature for later use

[0096] 2. Add phase A raw materials into the emulsification pot one by one, stir fully (properly homogenized) evenly; under homogeneous conditions, slowly pump the material body of the water phase pot of B into the emulsification pot, and homogenize for 5-10 minutes; then put the raw materials of phase C Add to the emulsification pot in turn, stir and heat up to 80-85°C, keep warm for a certain period of time

[0097] 3. Cool down to about...

Embodiment 2

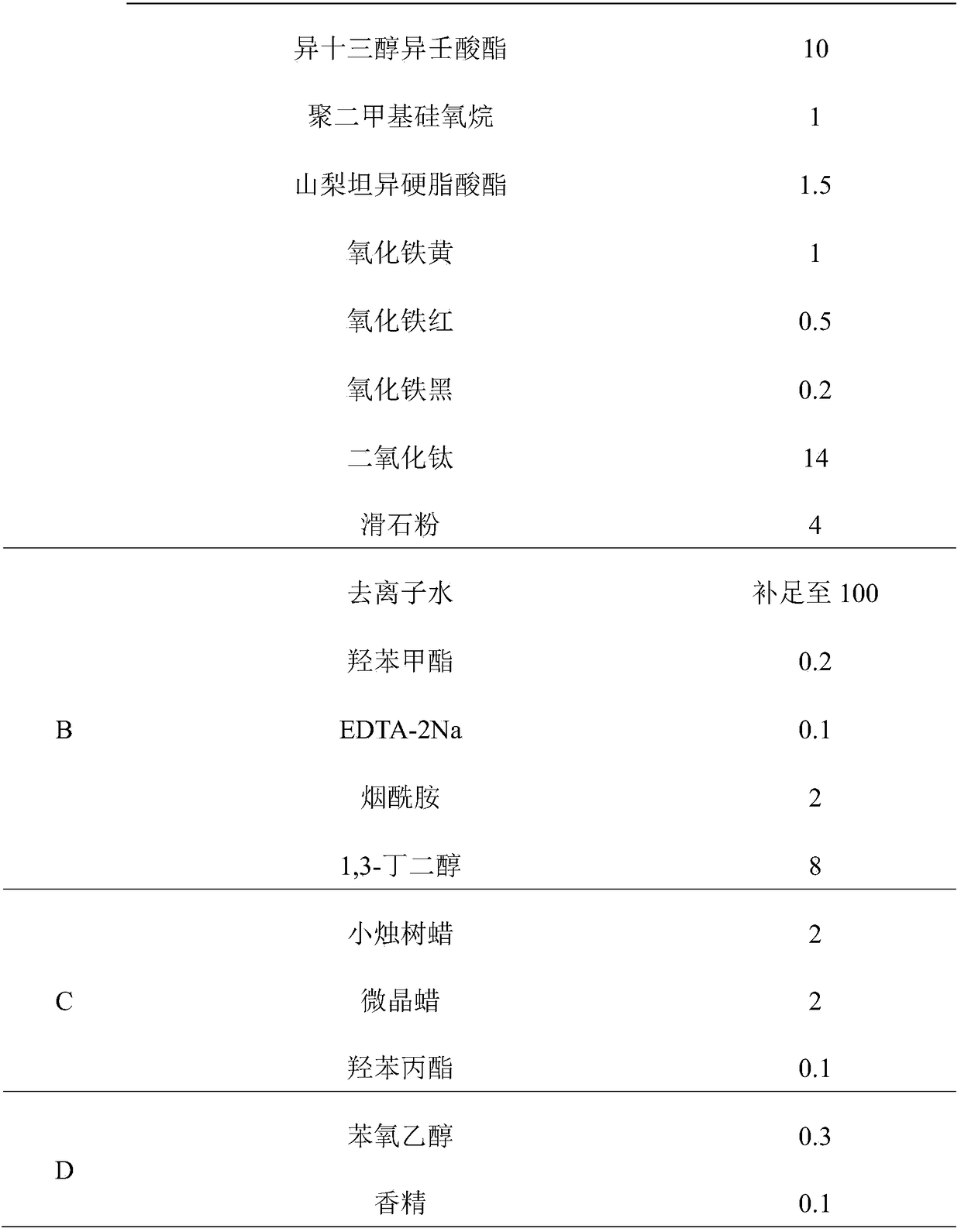

[0099] A water-in-oil type solid foundation cream, by weight percentage, its raw material components and contents are shown in the following table:

[0100] Table 2 The composition and content of water-in-oil type solid foundation cream of the present invention

[0101]

[0102] Preparation Process:

[0103] 1. Add the raw materials of phase B into the water phase pot one by one, stir and raise the temperature to 60-70°C, stir until the powder is fully dissolved and transparent, then cool down to room temperature for later use

[0104]2. Add phase A raw materials into the emulsification pot one by one, stir fully (properly homogenized) evenly; under homogeneous conditions, slowly pump the material body of the water phase pot of B into the emulsification pot, and homogenize for 5-10 minutes; then put the raw materials of phase C Add to the emulsification pot in turn, stir and heat up to 80-85°C, keep warm for 30 hours

[0105] 3. Cool down to about 60-70°C, homogenize agai...

Embodiment 3

[0107] A water-in-oil type solid foundation cream, by weight percentage, its raw material components and contents are shown in the following table:

[0108] Table 3 composition and content of water-in-oil type solid foundation cream of the present invention

[0109]

[0110]

[0111] Preparation Process:

[0112] 1. Add the raw materials of phase B into the water phase pot one by one, stir and raise the temperature to 60-70°C, stir until the powder is fully dissolved and transparent, then cool down to room temperature for later use

[0113] 2. Add phase A raw materials into the emulsification pot one by one, stir fully (properly homogenized) evenly; under homogeneous conditions, slowly pump the material body of the water phase pot of B into the emulsification pot, and homogenize for 5-10 minutes; then put the raw materials of phase C Add to the emulsification pot in turn, stir and heat up to 80-85°C, keep warm for a certain period of time

[0114] 3. Cool down to about...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com