Two-machine linkage processing method and system based on 3D metal printing

A processing system and 3D technology, applied in the field of 3D metal printing, can solve the problems of prolonged processing time, small working space, limited powder bed space, etc., to improve the quality of parts, improve production efficiency, and solve the effect of taking a long time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

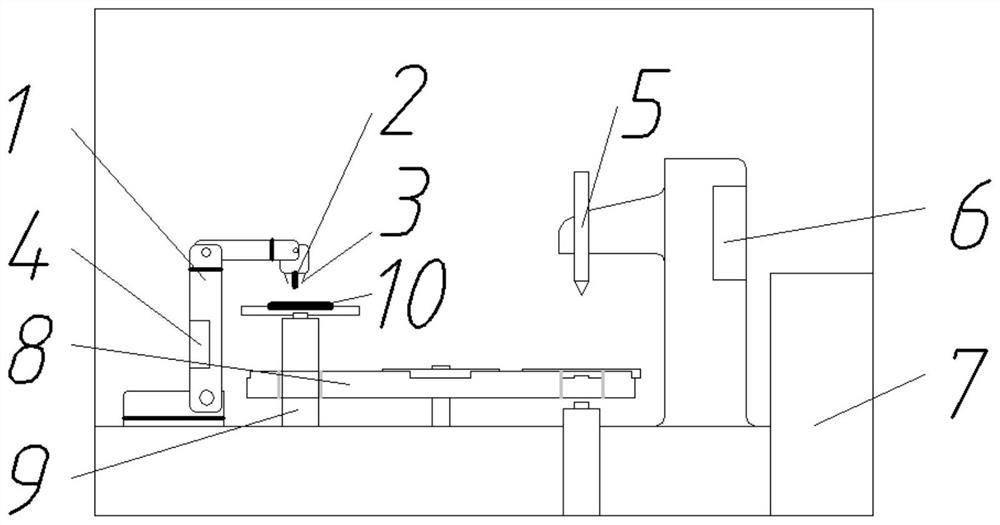

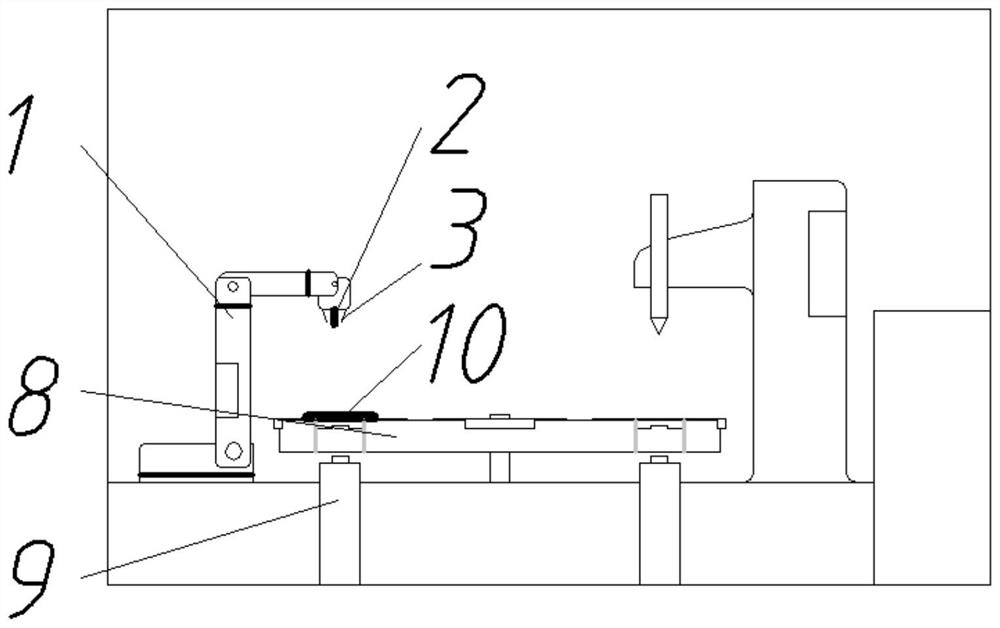

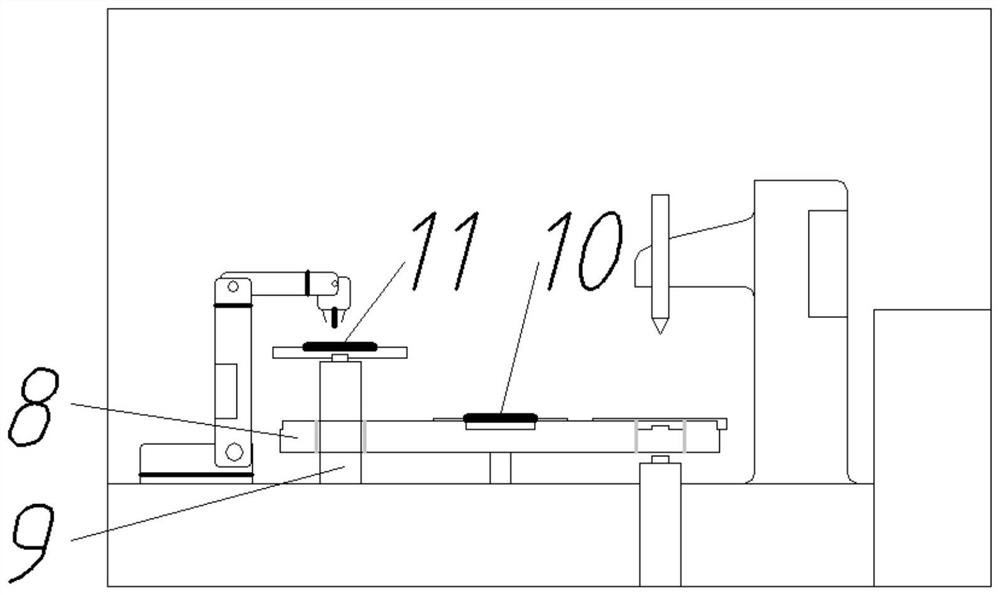

[0060] The present invention provides a novel processing system using a customized turntable connected to a laser deposition device and a CNC milling machine, with the purpose of maximizing the utilization of the equipment and improving the overall quality of the produced parts at the same time. The structure of the turntable in the present invention will change flexibly according to the characteristics of the parts, so it is impossible to show all the designs in this manual. It should be noted that all modifications based on concepts and principles of this technical system should exist within the scope of patent protection. As mentioned above, this manual will use the turntable st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com