A double-sided welding method for arc T-shaped fillet joints

A double-sided welding and arc technology, which is applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems that cannot meet the welding accuracy requirements of arc welds, and achieve the effect of meeting welding accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

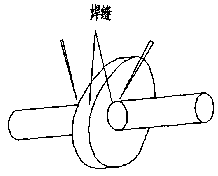

[0027] Such as figure 1 with image 3 As shown, the present embodiment provides a double-sided welding method for arc T-shaped fillet joints of arc workpieces with closed structure, including the following steps:

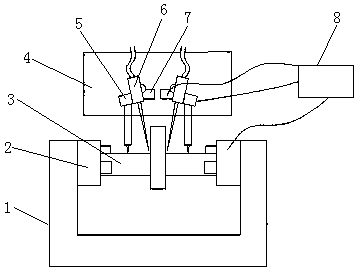

[0028] Firstly, the arc workpiece 3 to be welded is fixed by the fixture, and the fixture and the laser beam produce relative movement along the direction of the welding seam. Among them, such as image 3 As shown, the tooling fixture is a pneumatic claw-type fixture, including a base 1 with a concave groove structure and two rotating pneumatic jaws 2, and the two rotating pneumatic jaws 2 are symmetrically arranged on the base 1 respectively. 1 on both sides of the wall, such as figure 1 The two ends of the circular arc workpiece 3 of the closed structure shown are respectively installed in the two said rotary pneumatic jaws 2, and the circular arc workpiece 3 is clamped by rotating the pneumatic jaws 2, while the rotary pneumatic jaws 2 can drive The arc workp...

Embodiment 2

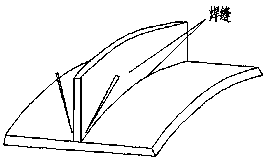

[0034] Such as figure 2 with Figure 4 As shown, the present embodiment provides a double-sided welding method for arc T-shaped fillet joints of arc workpieces with segmented structure, including the following steps:

[0035] Firstly, the arc workpiece 3 to be welded is fixed by the fixture, and the fixture can drive the arc workpiece 3 to move along the welding seam track. And for such as figure 2 The arc workpiece 3 with segmented structure shown in the present embodiment, the tooling fixture is a profiled surface clamping and positioning fixture, including a concave groove structure of the machine base 2 9, two mobile tooling supports 10 and setting The profiling support 11 plate and the clamp 12 on the mobile tooling support 10, the two side walls of the said machine base 9 are provided with long guide rails, and the two said mobile tooling supports 10 are respectively symmetrically slidably connected to the said machine base two 9, the profiling pallet 11 is located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com