A kind of micro-led chip and its preparation method, display device

A display device and chip technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as the inability to meet the welding accuracy requirements of Micro-LED chips, and achieve the effect of reducing manufacturing costs and meeting welding accuracy requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

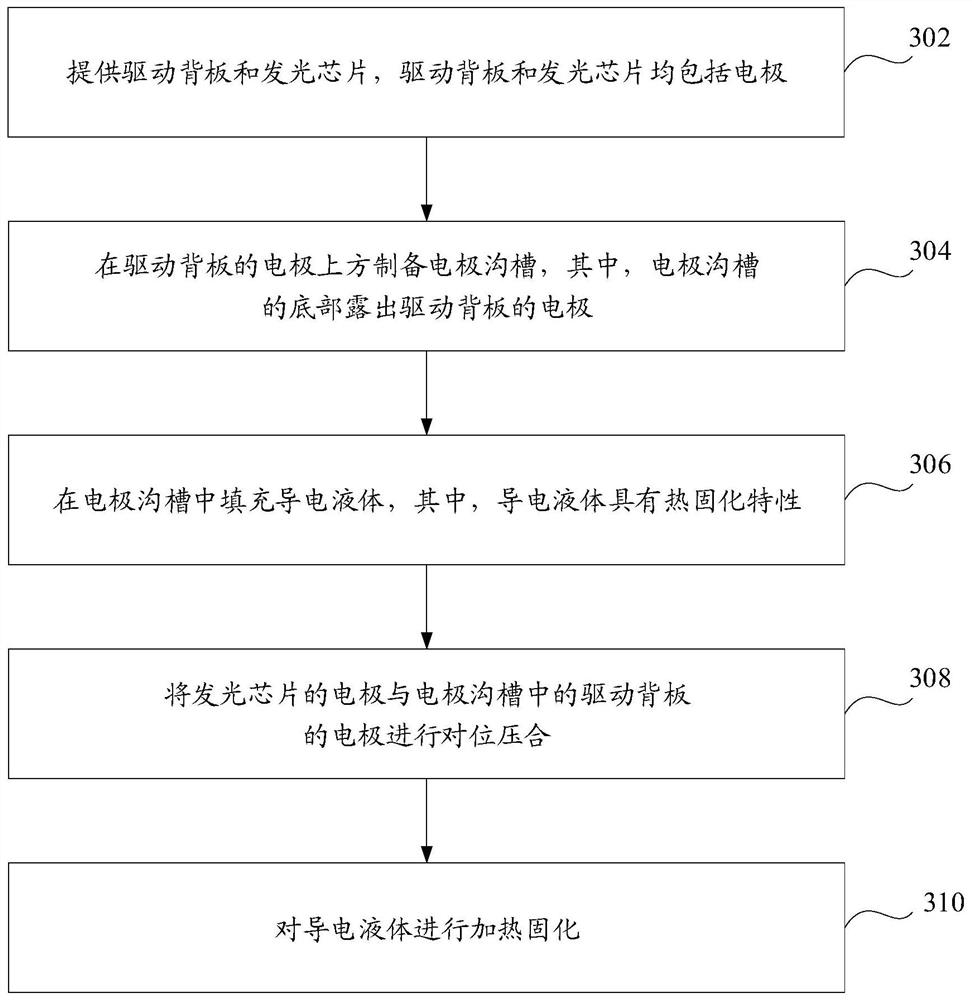

[0045] At present, when preparing Micro-LED chips, due to the incompatibility of the process flow, the light-emitting chip and the driving backplane contained in the Micro-LED chip need to be prepared separately. After the light-emitting chip and the driving backplane are prepared, the electrodes of the light-emitting chip and the electrodes of the driving backplane can be electrically connected, so that the driving backplane can drive the light-emitting chip to emit light.

[0046] In the prior art, the light-emitting chip contained in the Micro-LED chip and the driving backplane are usually welded by a flip-chip welding process, so as to realize the electrical connection between the light-emitting chip and the driving backplane.

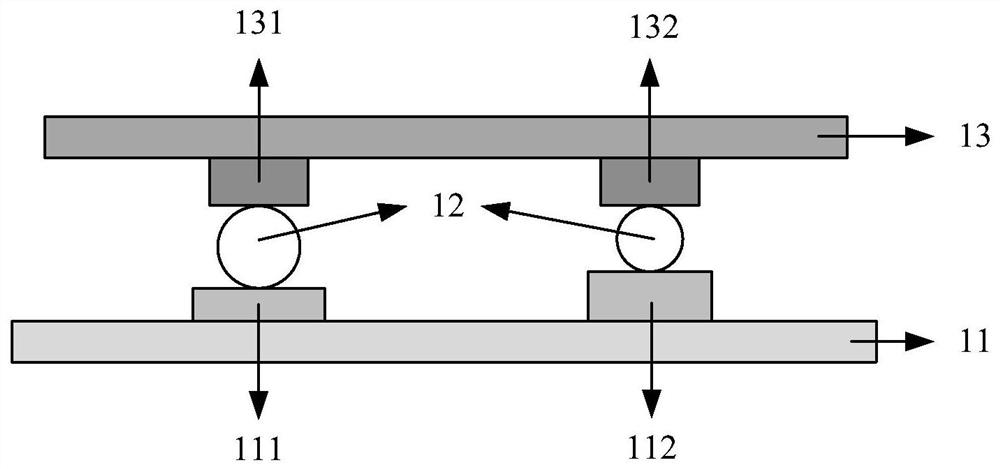

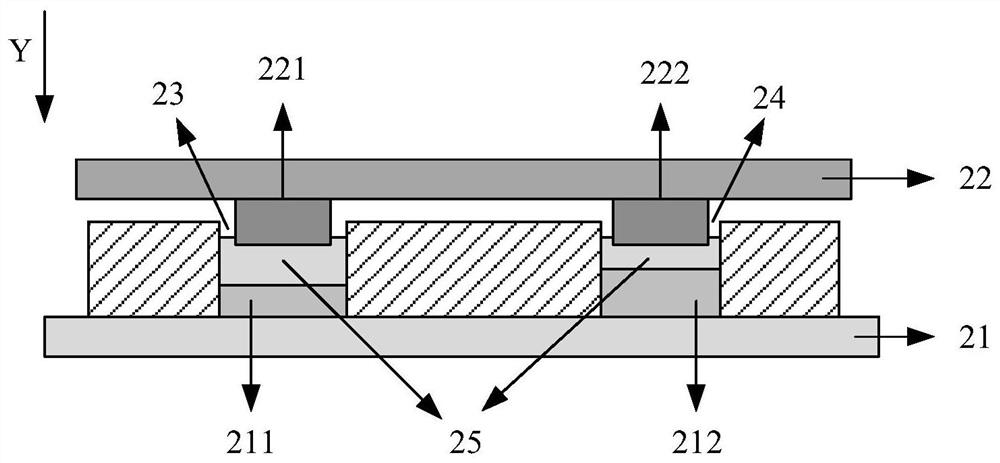

[0047] figure 1 It is a schematic diagram of realizing the electrical connection between the light-emitting chip and the driving backplane by flip-chip welding process in the prior art. Such as figure 1 As shown, first, the solder 12 can be prepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com