Anti-deformation automatic protection pneumatic bench vise

An automatic protection and anti-deformation technology, applied in vices, manufacturing tools, etc., can solve problems such as unfavorable processing efficiency, loose clamping of workpieces, extrusion deformation of workpieces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

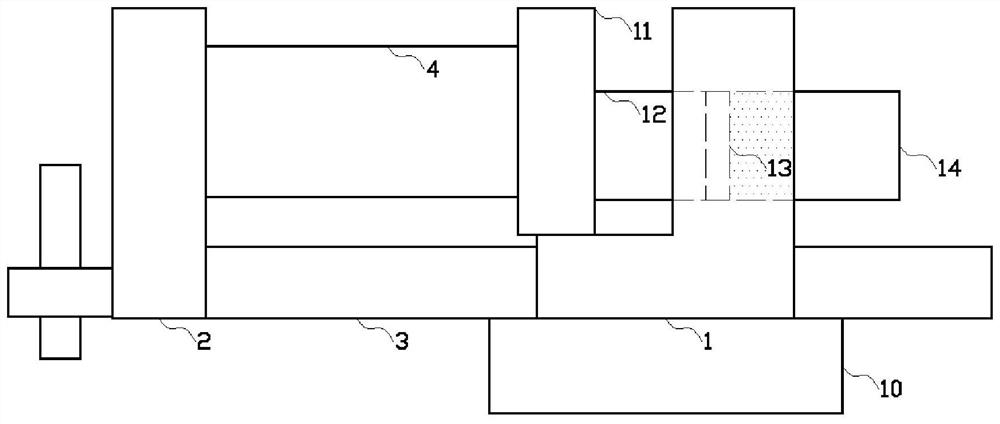

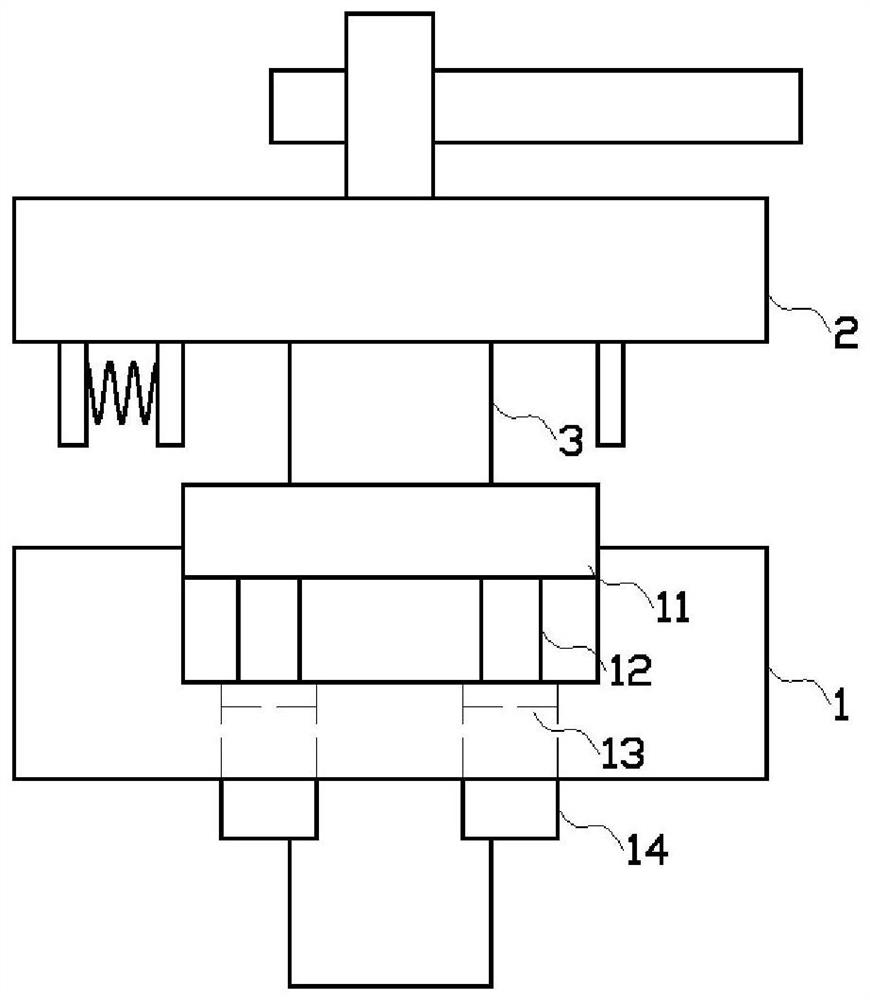

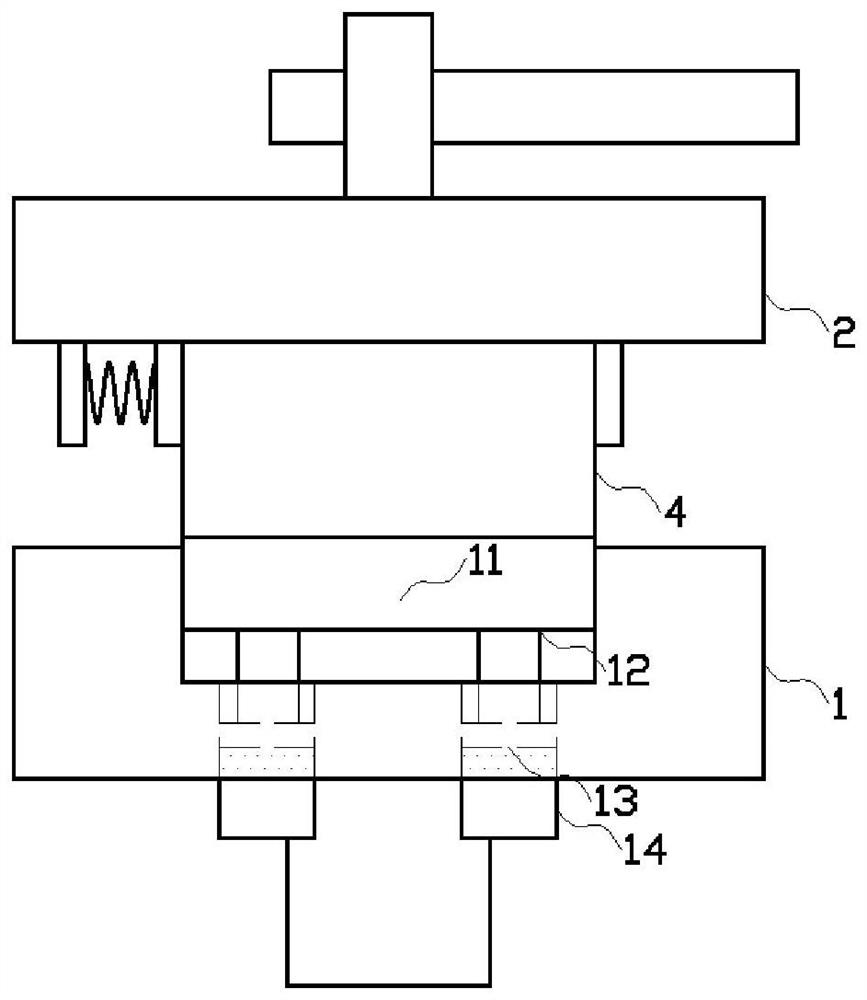

[0013] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

[0014] Such as figure 1 , figure 2 , image 3 As shown in the embodiment, the anti-deformation automatic protection air pressure bench vise is a kind of automatic detection of the change of the clamping force on the workpiece when tightening through the adjustment of the air pressure, and automatically loosens to protect the workpiece when excessive tightening occurs. In addition, the device that shortens the clamping and correction time of the workpiece and improves the clamping efficiency includes a fixed jaw module 1; a turntable seat 10 is arranged at the bottom of the fixed jaw module 1, and A sliding hole is provided, and a nut is fixedly installed in the sliding hole, and a screw rod 3 is assembled in the nut; a movable jaw module 2 is arranged in front of the fixed jaw module 1, and the movable jaw module 2 includes screw rod 3 rocker, the screw rod 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com