Integrated-type air braking system for new energy commercial vehicle

A commercial vehicle, integrated technology, applied in the direction of brakes, brake transmissions, vehicle components, etc., can solve problems such as the inability to realize flexible and rapid start and variable speed operation of the motor, the increase of pipeline connection joints, and the inconvenience of installation and maintenance. Eliminate incomplete separation or failure of separation filter element, save installation space, and facilitate installation and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

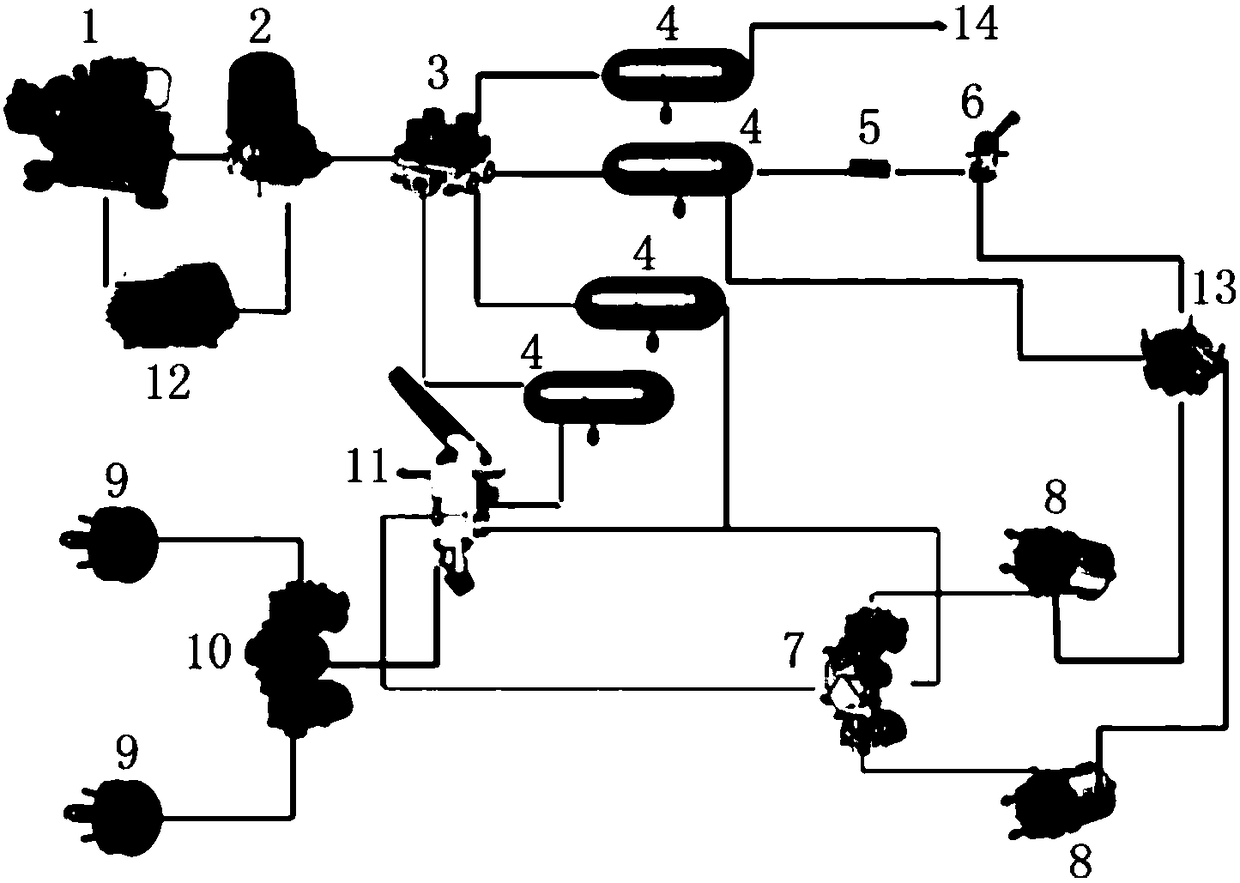

[0026] Combine below Figure 1-5 Describe in detail the technical solution of the integrated air brake system for new energy commercial vehicles:

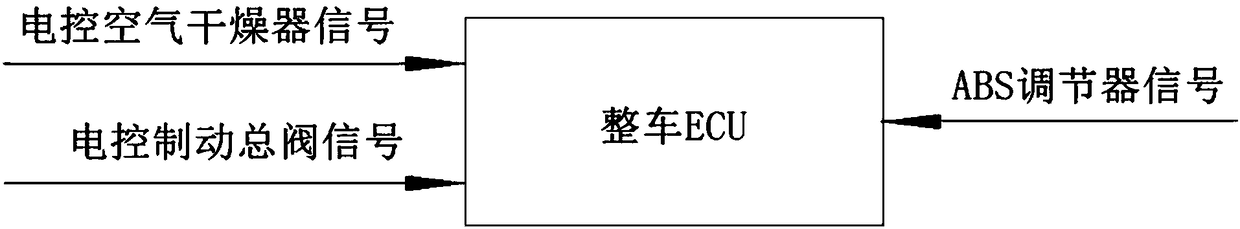

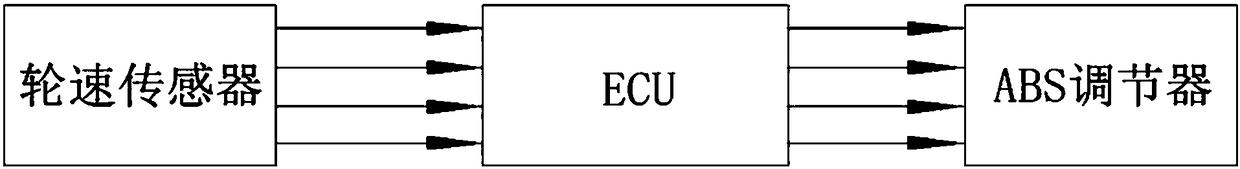

[0027] Integrated air brake system for new energy commercial vehicles, including ECU, electric brake master valve 11, two piston spring brake chambers 8, manual relay valve 13, the ECU and electric brake master valve 11, and also includes an ABS regulator and a relay valve integration module 7, the ECU and the electronically controlled brake master valve 11 are respectively connected with the ABS regulator and the relay valve integration module 7, and the ABS regulator and the relay valve The integrated module 7 is connected with the brake chambers of the two piston spring brake chambers 8 , and the manual relay valve 13 is connected with the parking chambers of the two piston spring brake chambers 8 . It includes two front brake sub-chambers 9, an ABS regulator and a quick release valve integrated module 10, one end of the ABS re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com