Method for preparing petunidin-3-O-glucoside by separation

A technology of petunienin and glucoside, which is applied in the field of separation and preparation of petunienin-3-O-glucoside, and can solve the problems of undiscovered separation and preparation of petunin-3-O-glucoside monomers. Reporting and other problems, to achieve the effect of large sample processing volume and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

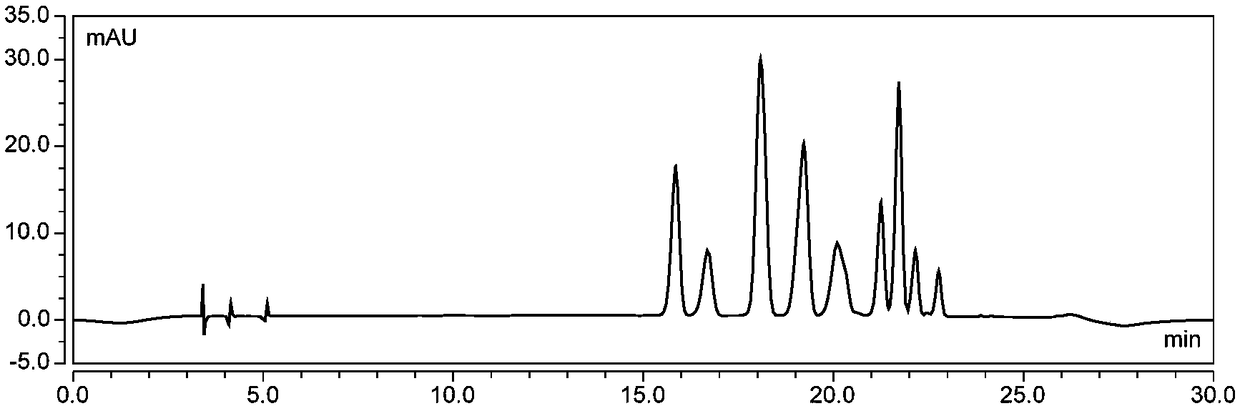

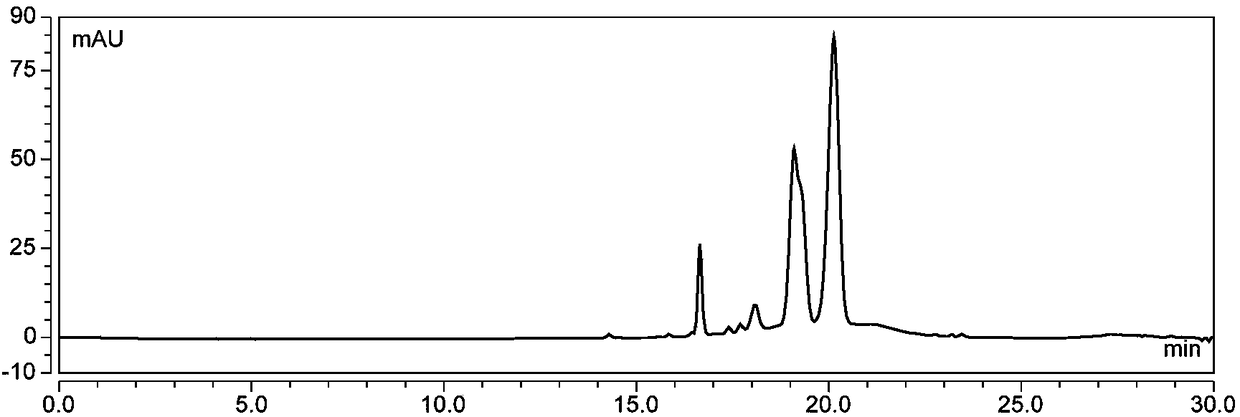

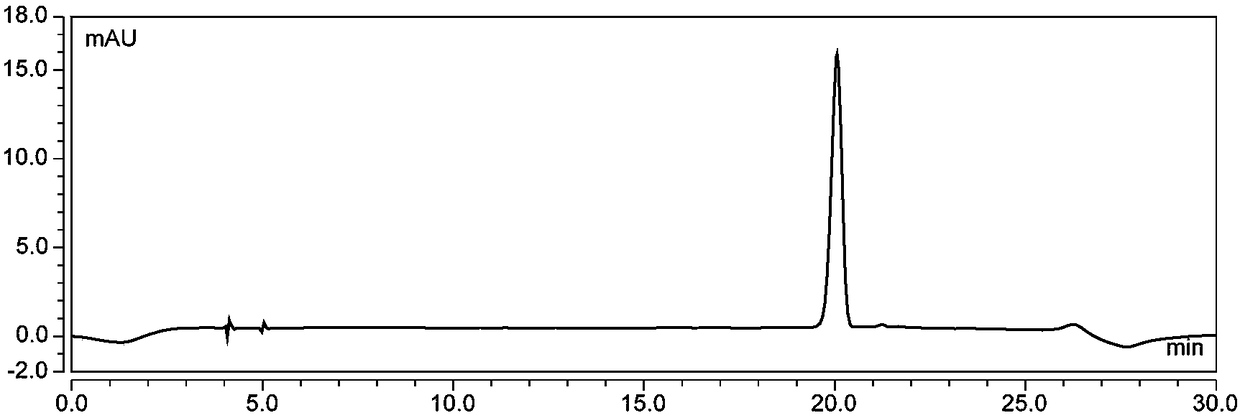

Image

Examples

Embodiment 1

[0066] Wash 1kg of fresh blueberries, add 70% ethanol aqueous solution containing 0.1% (v / v) hydrochloric acid (the volume ratio of ethanol to water is 70 : 30) fully mixed, ultrasonically extracted for 90min, (control temperature below 45°C, protected from light), vacuum filtration after the end of ultrasonication, repeated extraction of the obtained filter residue once according to the above conditions, combined filtrate, and removed by vacuum rotary evaporation at 45°C ethanol to obtain the crude extract of anthocyanins.

[0067] Soak the AB-8 macroporous resin in ethanol for 24 hours, put it into the chromatography column, wash it with pure water until there is no alcohol smell, wash it with 0.5M sodium hydroxide solution at a flow rate of 2BV / h for 1 hour, and then wash it with deionized water until the effluent is neutral; then use 0.5M hydrochloric acid solution to rinse for 1 hour at a flow rate of 2BV / h, and then rinse with deionized water until neutral. The crude an...

Embodiment 2

[0072] Wash 5kg of fresh blueberries, add 70% ethanol solution containing 0.5% (v / v) hydrochloric acid according to the ratio of material to liquid (w / v) to fully mix, and extract by ultrasonic for 150min, (control the temperature at 45°C hereinafter, protected from light), vacuum suction filtration after the end of ultrasonication, repeated extraction of the obtained filter residue once according to the above conditions, combined filtrates, and removed ethanol by vacuum rotary evaporation at 45° C. to obtain crude anthocyanin extracts.

[0073] Soak the AB-8 macroporous resin in ethanol for 24 hours, put it into the chromatography column, wash it with pure water until there is no alcohol smell, wash it with 0.5M sodium hydroxide solution at a flow rate of 2BV / h for 1 hour, and then wash it with deionized water until the effluent is neutral; then use 0.5M hydrochloric acid solution to rinse for 1 hour at a flow rate of 2BV / h, and then rinse with deionized water until neutral. ...

Embodiment 3

[0077] Wash 10kg of fresh blueberries, add 60% ethanol solution containing 0.1% (v / v) hydrochloric acid according to the ratio of solid to liquid (1:5 (w / v)) and mix thoroughly, ultrasonically extract for 200min, (control the temperature at 45°C hereinafter, protected from light), vacuum suction filtration after the end of ultrasonication, repeated extraction of the obtained filter residue once according to the above conditions, combined filtrates, and removed ethanol by vacuum rotary evaporation at 45° C. to obtain crude anthocyanin extracts.

[0078]Soak the AB-8 macroporous resin in ethanol for 24 hours, put it into the chromatography column, wash it with pure water until there is no alcohol smell, wash it with 0.5M sodium hydroxide solution at a flow rate of 2BV / h for 1 hour, and then wash it with deionized water until the effluent is neutral; then use 0.5M hydrochloric acid solution to rinse for 1 hour at a flow rate of 2BV / h, and then rinse with deionized water until neut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com