Glue for water-based spray glue, water-based spray glue and preparation method thereof

A spraying, water-based technology, used in adhesives, chloroprene adhesives, non-polymer adhesive additives, etc., can solve the problems of difficulty in use, slow curing, low initial tack, etc., and achieve compatibility Good, good bonding effect, the effect of improving initial adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] A preparation method for water-based spray glue, comprising the steps of:

[0016] a take neoprene latex, rosin emulsion, C5 petroleum resin, acrylic acid emulsion, polyaziridine cross-linking agent and pH regulator by proportioning;

[0017] b Mix and stir the components weighed in step a to obtain the glue component; specifically, stir for 60 min at a stirring speed of 400r / min, and add water in step a to adjust the viscosity of the glue component according to actual needs dilution;

[0018] c mix and stir calcium chloride and water to obtain a demulsifier. Specifically, stirring for 60 min at a stirring speed of 500 r / min.

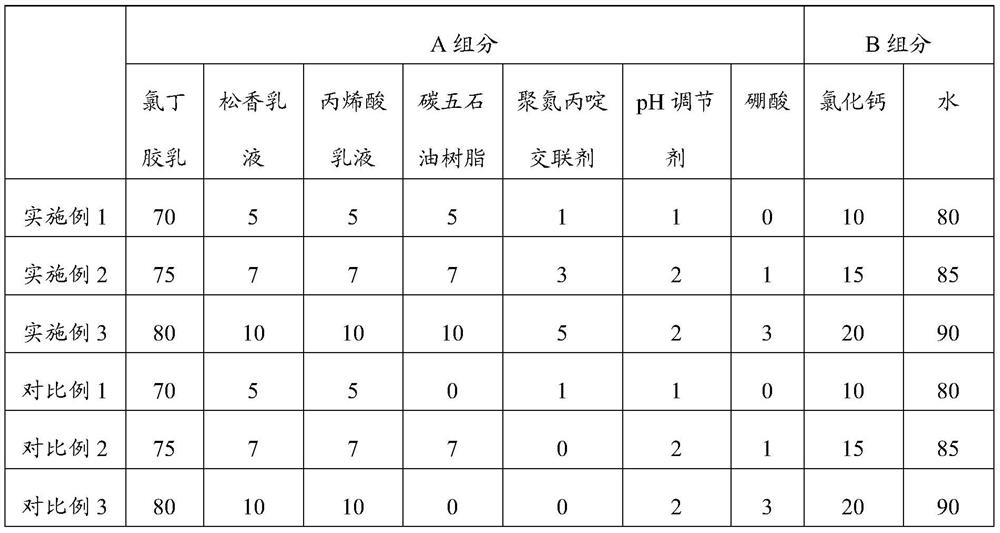

Embodiment 1

[0023] The preparation method of the water-based spray glue of embodiment 1 and comparative example 1:

[0024] a take by weighing neoprene latex, rosin emulsion, C5 petroleum resin, acrylic acid emulsion, polyethylenimine crosslinking agent, pH regulator, calcium chloride and water by proportioning, wherein pH regulator selects glycine for use, does not have in comparative example 1 C5 petroleum resin;

[0025] b Mix and stir neoprene latex, rosin emulsion, carbon five petroleum resin, acrylic emulsion and polyethylenimine crosslinking agent, adjust the pH with glycine to make the pH in the range of 9-10, and then stir at a speed of 400r / min Stir down for 60min to make water-based spray glue (A component);

[0026] c. Mix calcium chloride and water to obtain a demulsifier, and stir at a stirring speed of 500r / min for 60min to obtain a demulsifier (component B).

[0027] The A component and the B component of the water-based spray glue prepared according to the ratio of Exam...

Embodiment 2

[0028] The preparation method of the water-based spray glue of embodiment 2 and comparative example 2:

[0029] a take by weighing neoprene latex, rosin emulsion, C5 petroleum resin, acrylic acid emulsion, polyaziridine crosslinking agent, boric acid, pH regulator, calcium chloride and water, wherein pH regulator selects acetic acid for use, comparative example 2 There is no polyethylenimine cross-linking agent;

[0030] b Mix and stir neoprene latex, rosin emulsion, carbon five petroleum resin, acrylic emulsion, polyaziridine crosslinking agent and boric acid, adjust the pH with acetic acid to make the pH in the range of 9-10, and then use 400r / min Stir at a stirring speed for 60 minutes to prepare water-based glue for spraying glue (component A);

[0031] c. Mix calcium chloride and water to obtain a demulsifier, and stir at a stirring speed of 500r / min for 60min to obtain a demulsifier (component B).

[0032] The A component and the B component of the water-based spray gl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com