Processing process of edible oil

A processing technology and edible oil technology, applied in the direction of fat oil/fat production, fat oil/fat refining, fat production, etc., can solve the problems of oil chemical residues, negative impact on human body, low pressing efficiency, etc., to achieve good dephosphorization, The effect of reducing the cost of pressing and reducing the amount of soot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

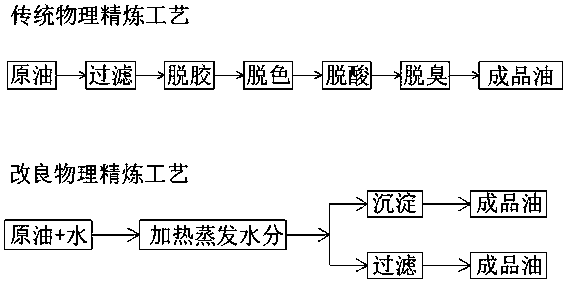

Method used

Image

Examples

Embodiment 1

[0025] A case based on peanut oil pressing:

[0026] Peanut oil processing technology, including cold pressing technology;

[0027] The cold pressing process comprises the following steps:

[0028] Material selection: choose high-quality and plump peanut fruit;

[0029] Shell surface cleaning treatment: use water washing to clean the shell surface;

[0030] Shelling: use a shelling machine to separate the shell and fruit;

[0031] Nut cleaning treatment: the peanut kernels are cleaned by washing;

[0032] Low-temperature cold pressing: use a press to perform low-temperature pressing to produce crude oil;

[0033] The peanut oil processing technology also includes the following refining processes:

[0034] 1) Put 100kg of crude oil formed in the cold pressing process into a clean pot;

[0035] 2) Pour 1kg of pure water into the pot with crude oil;

[0036] 3) Slowly heat for 3-10min at the bottom of the pot until steam emerges from the upper oil layer, then use high heat...

Embodiment 2

[0040] A case based on rapeseed oil crushing:

[0041] Peanut oil processing technology, including cold pressing technology;

[0042] The cold pressing process comprises the following steps:

[0043] Material selection: choose high-quality and plump rapeseed fruits;

[0044] Nut cleaning treatment: the rapeseed is cleaned by washing with water;

[0045] Low-temperature cold pressing: use a press to perform low-temperature pressing to produce crude oil;

[0046] The peanut oil processing technology also includes the following refining processes:

[0047] 1) Put 100kg of crude oil formed in the cold pressing process into a clean pot;

[0048] 2) Pour 1.5kg of pure water into the pot with crude oil;

[0049] 3) Slowly heat for 3-10 minutes at the bottom of the pot until steam emerges from the upper oil layer, then use high heat to heat until the surface of the upper oil layer no longer generates steam, which means that the water in the oil has basically evaporated and stop h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com