Unsymmetrical loading shallow-buried tunnel port construction protection structure and construction method thereof

A technology for shallow buried tunnels and protective structures, applied in infrastructure engineering, tunnels, tunnel linings, etc., can solve the problems of disturbing the original mountain, limited anti-bias pressure ability, and original ecological damage, so as to reduce the amount of engineering and avoid disturbance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and embodiment the present invention is described further as follows:

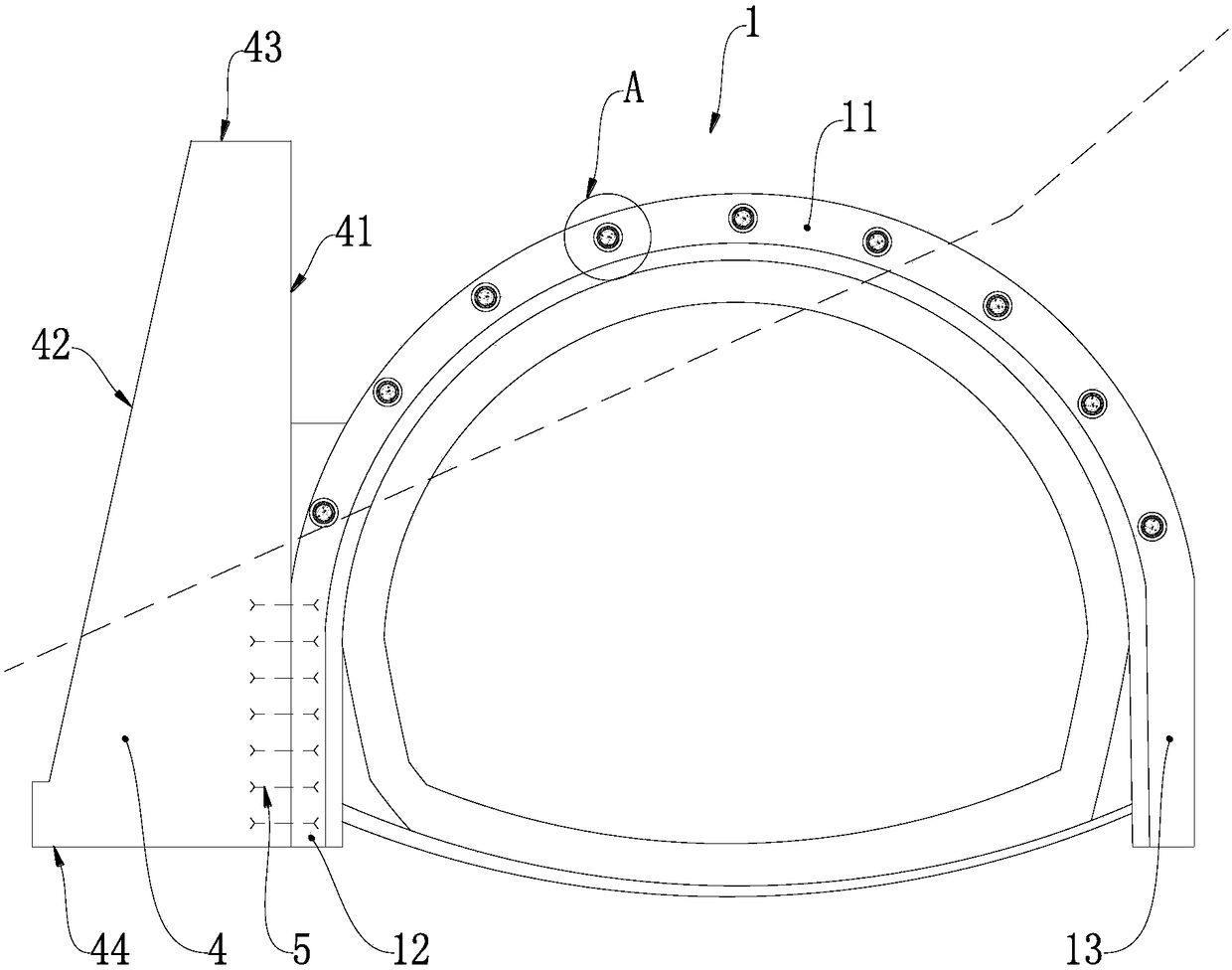

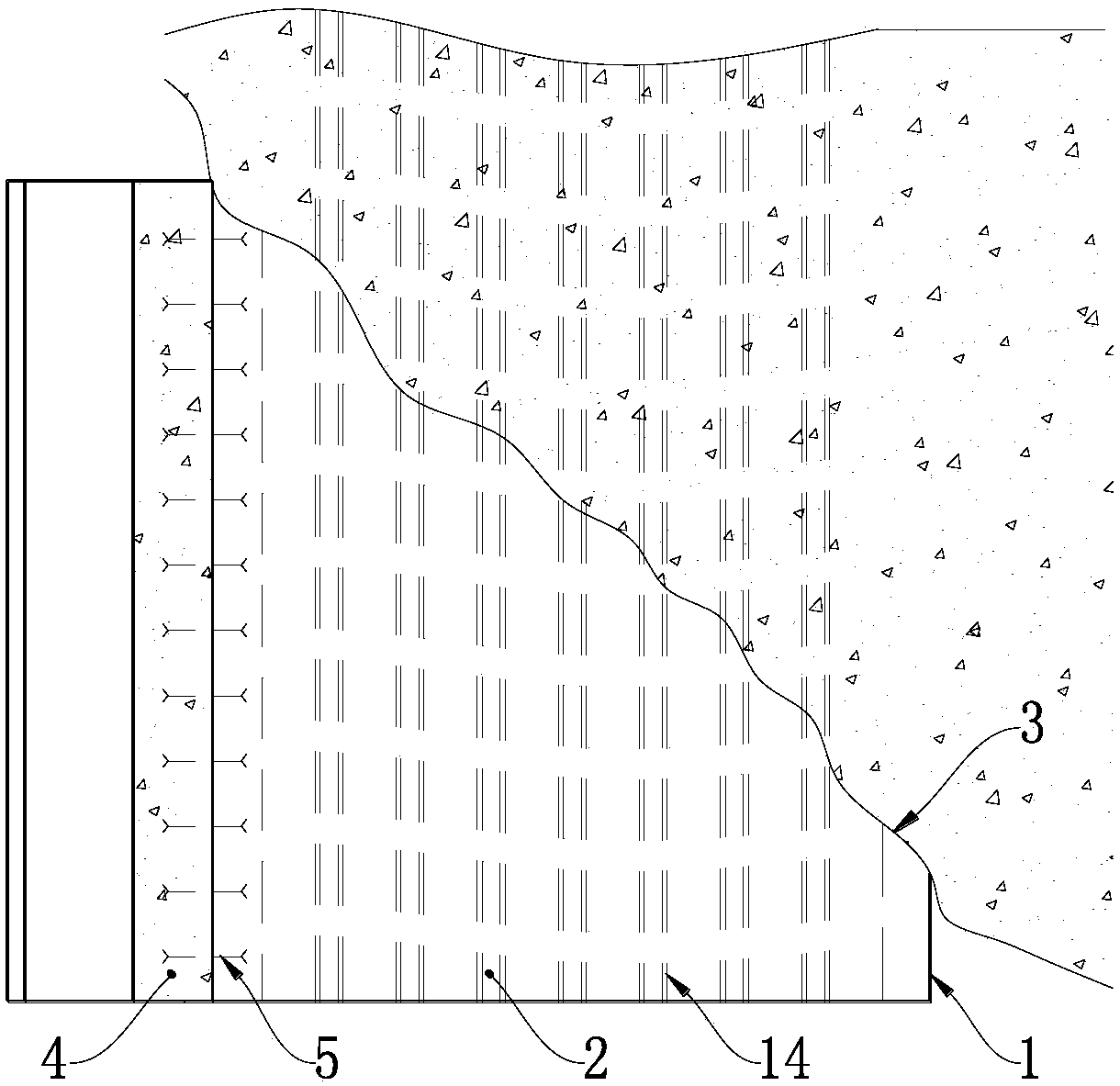

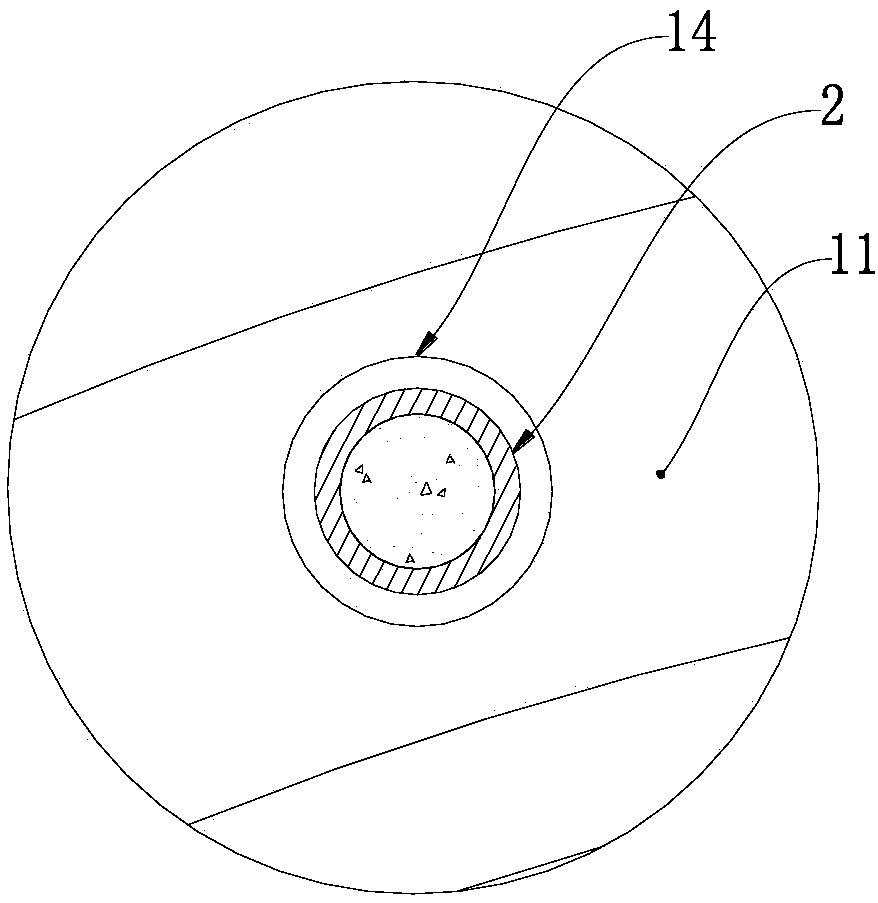

[0030] Such as figure 1 , figure 2 and image 3 As shown, the construction protection structure of the bias pressure shallow buried tunnel entrance includes a protection arch 1 and a pipe shed. The pipe shed includes a group of grouted steel pipes 2 filled with cement slurry; The inner end of the arch 1 extends to the slope surface 3 of the mountain; the protective arch 1 includes a vault section 11 at the top along its circumference, and shallow buried side arch feet 12 and deep buried side arch feet 13 on both sides; Section 11 is provided with a group of guide holes 14 through its outer end to the inner end along its circumference, and the grouted steel pipe 2 extends into the mountain body through the guide holes 14; a gravity retaining wall 4 is also arranged on the outside of the mountain body. The gravity retaining wall 4 is arranged on the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com