Quick connector of microfluidic system

A microfluidic system and rapid technology, applied in the direction of control valves, functional valve types, engine components, etc., can solve the problems of cross contamination between liquids, difficulty in automatic connection, low connection accuracy, etc., to improve work efficiency, connect and Quick and efficient detachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

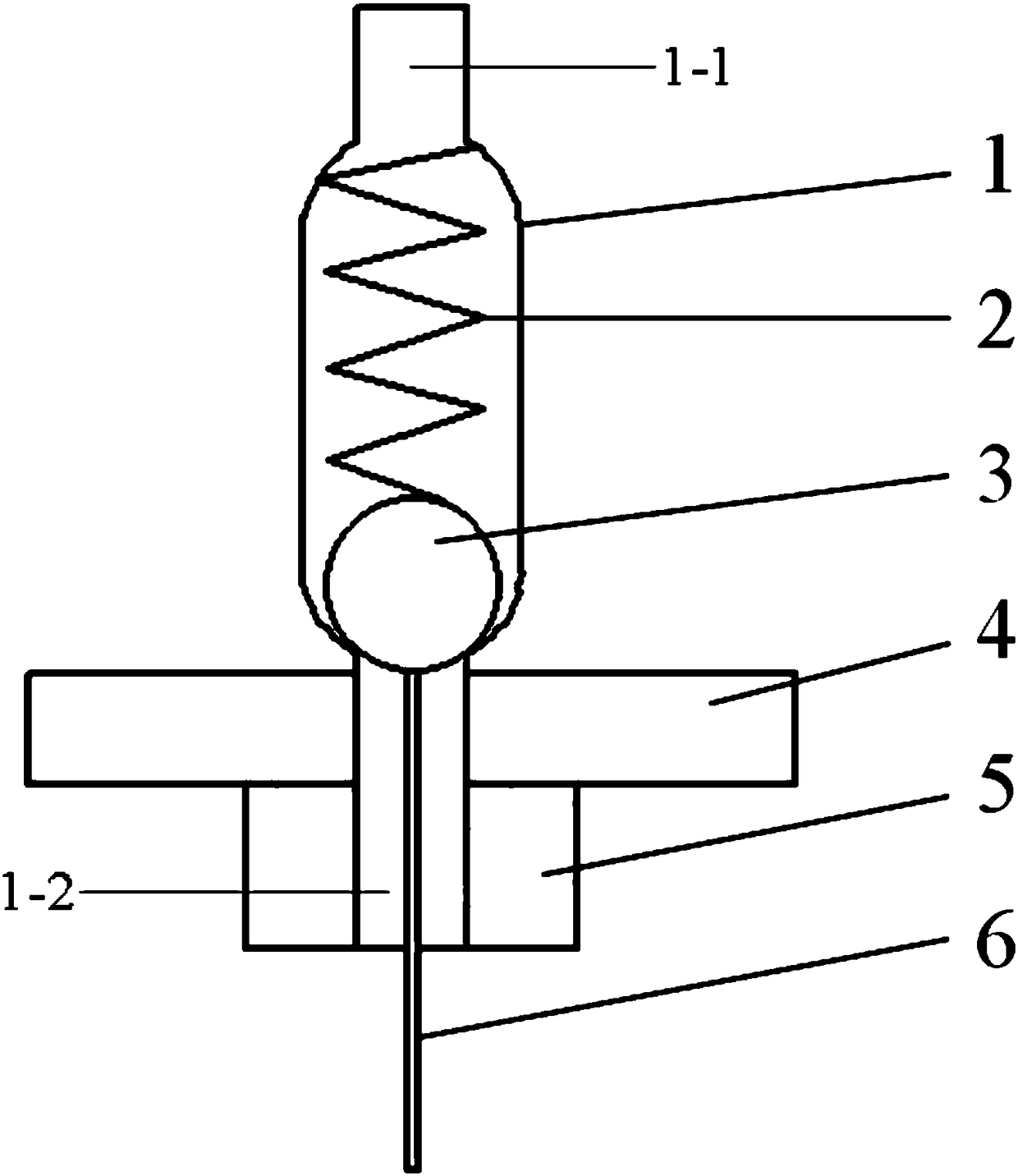

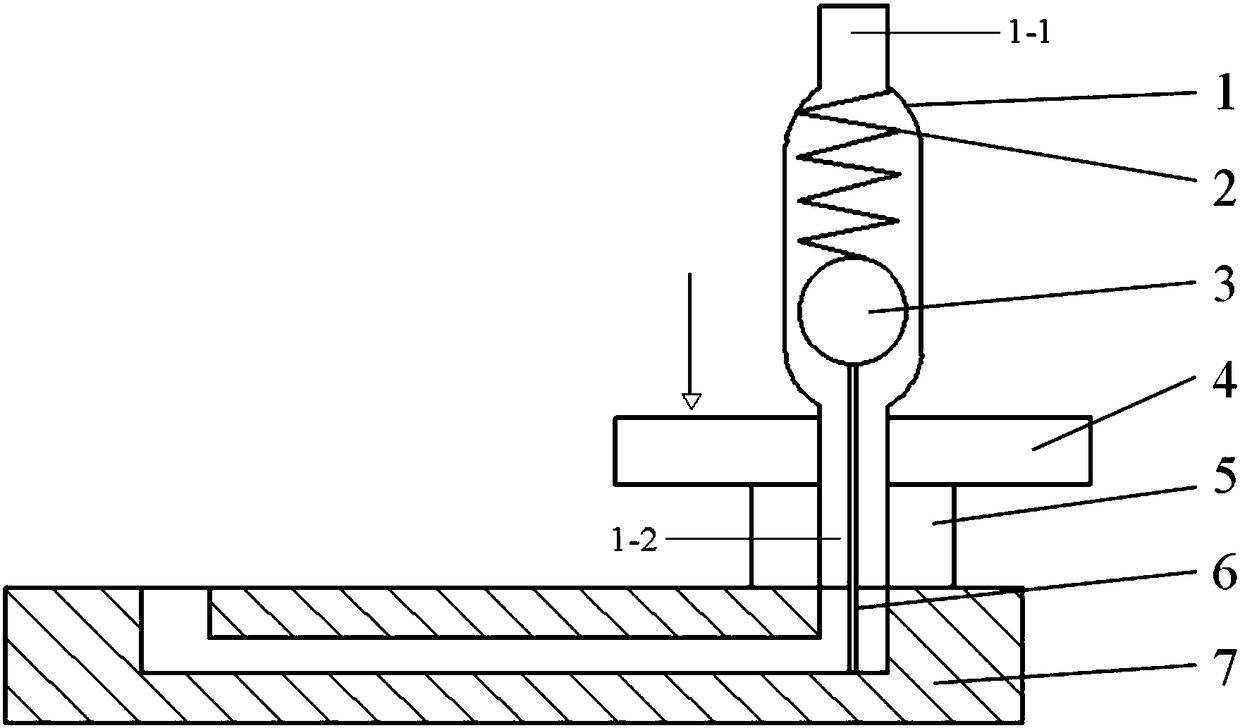

[0018] Specific implementation mode 1: This implementation mode is a quick connector of a microfluidic system, such as Figure 1-Figure 3 , which is specifically composed of a one-way valve, a compression clamp 4, a sealing ring 5 and a switch rod 6;

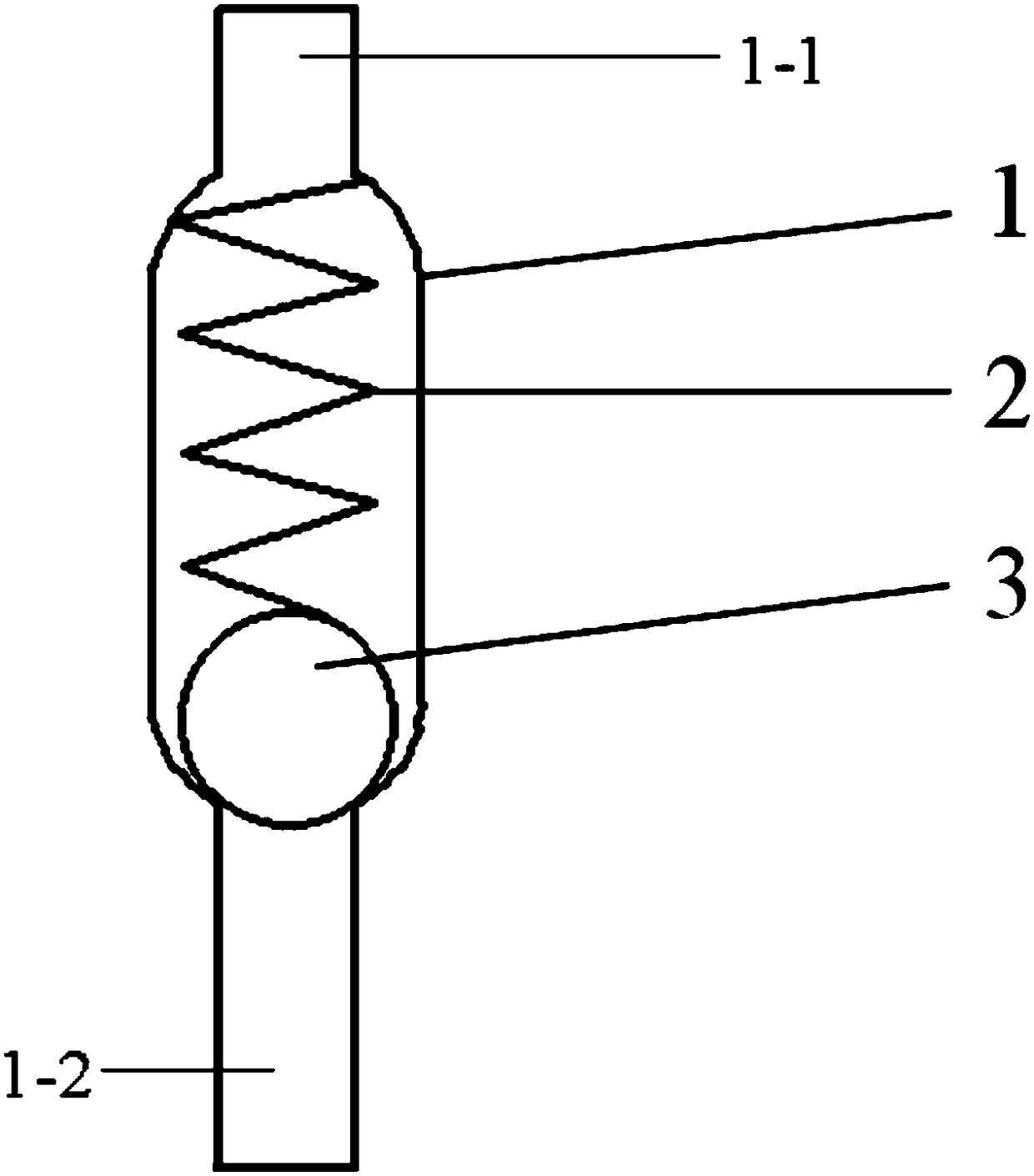

[0019] The one-way valve is composed of a valve body 1, a spring 2 and a spherical valve core 3;

[0020] The two ends of the valve body 1 are respectively the inlet 1-1 and the outlet 1-2 of the one-way valve, and the diameters of the inlet 1-1 and the outlet 1-2 of the one-way valve are smaller than the diameter of the middle part;

[0021] The spherical valve core 3 is arranged inside the middle part of the valve body 1 and close to the outlet 1-2 of the one-way valve, the spring 2 is arranged inside the middle part of the valve body 1 and close to the inlet 1-1 of the one-way valve, and the spring 2 is under compression state, the two ends of the spring 2 press the spherical valve core 3 and the inlet 1-1 of the check valve...

specific Embodiment approach 2

[0029] Embodiment 2: This embodiment is different from Embodiment 1 in that: the material of the clamp 4 is stainless steel or plastic. Others are the same as the first embodiment.

specific Embodiment approach 3

[0030] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the sealing ring 5 is made of rubber. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com