Tool axis vector fairing method based on kinematics characteristics of swivel feeding shaft of machine tool

A tool axis vector and feed axis technology, which is applied in the field of tool axis vector smoothing based on the kinematics of the machine tool's rotary feed axis, can solve the problems of being unsuitable for high-precision and high-efficiency machining, affecting machining efficiency, and requiring large amounts of calculation. To achieve the effect of improving the surface processing quality of the workpiece, improving the processing quality and efficiency, and improving the surface processing quality

Active Publication Date: 2018-08-17

DALIAN UNIV OF TECH

View PDF4 Cites 18 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, this method has a large amount of calculation and does not consider the kinematics of the machine tool's rotary feed axis during the optimization process, which has great limitations.

The literature by Zhou Bo et al. "Research on tool axis vector optimization method for five-axis CNC machining of complex curved surfaces", Chinese Journal of Mechanical Engineering, 2013, 49(7), 184-192, by inserting tool contacts in the non-interference area, in the interference area The improved C-space method is used to generate a smooth tool axis vector. This method can handle global interference and local interference, but inserting a tangential point reduces the actual feed rate and affects processing efficiency. It is not suitable for high-precision and high-efficiency processing.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

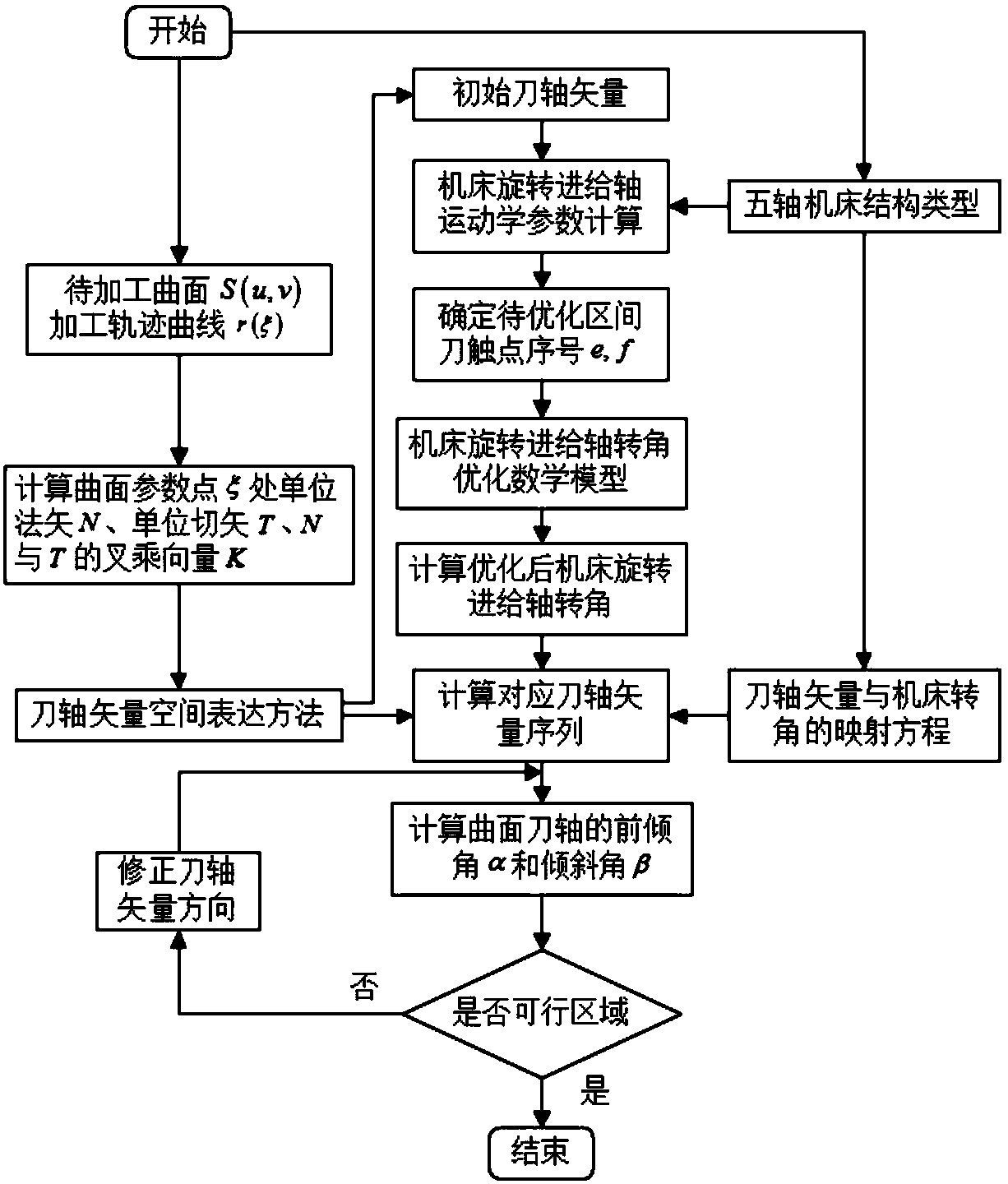

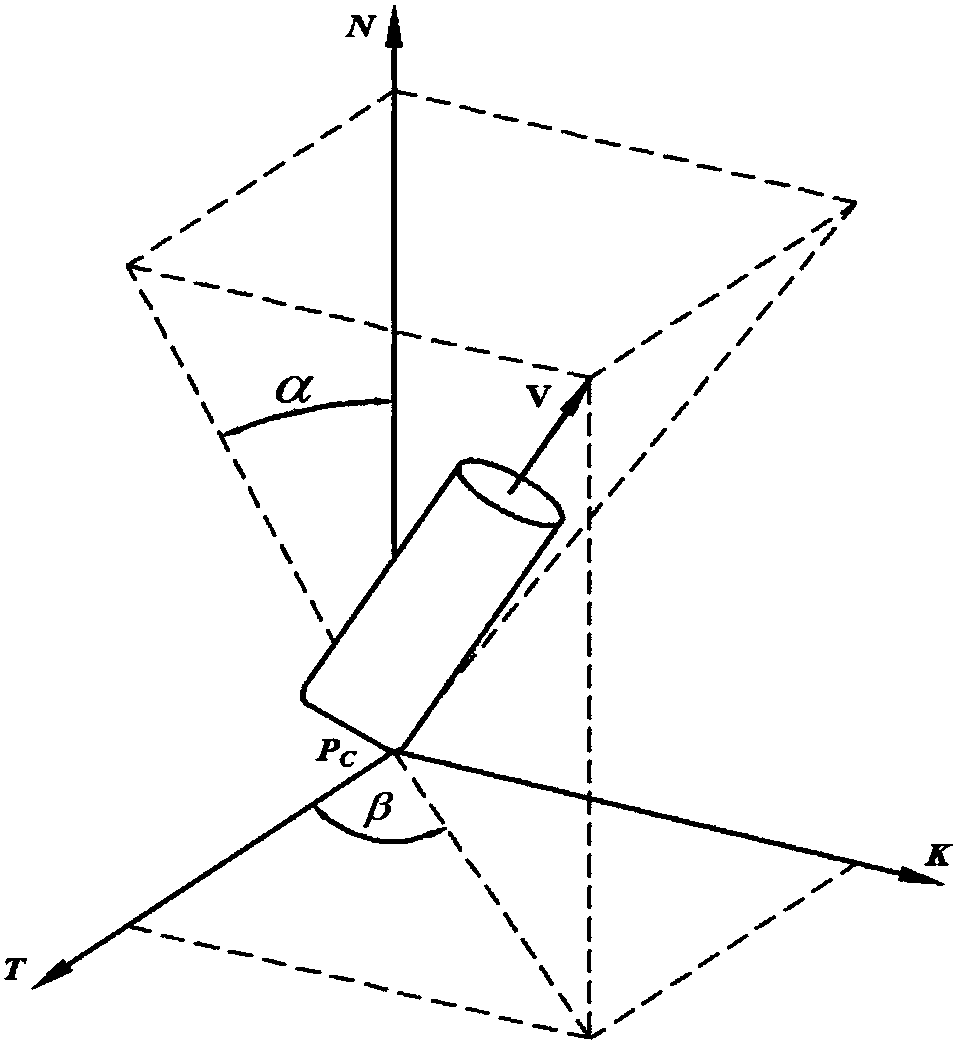

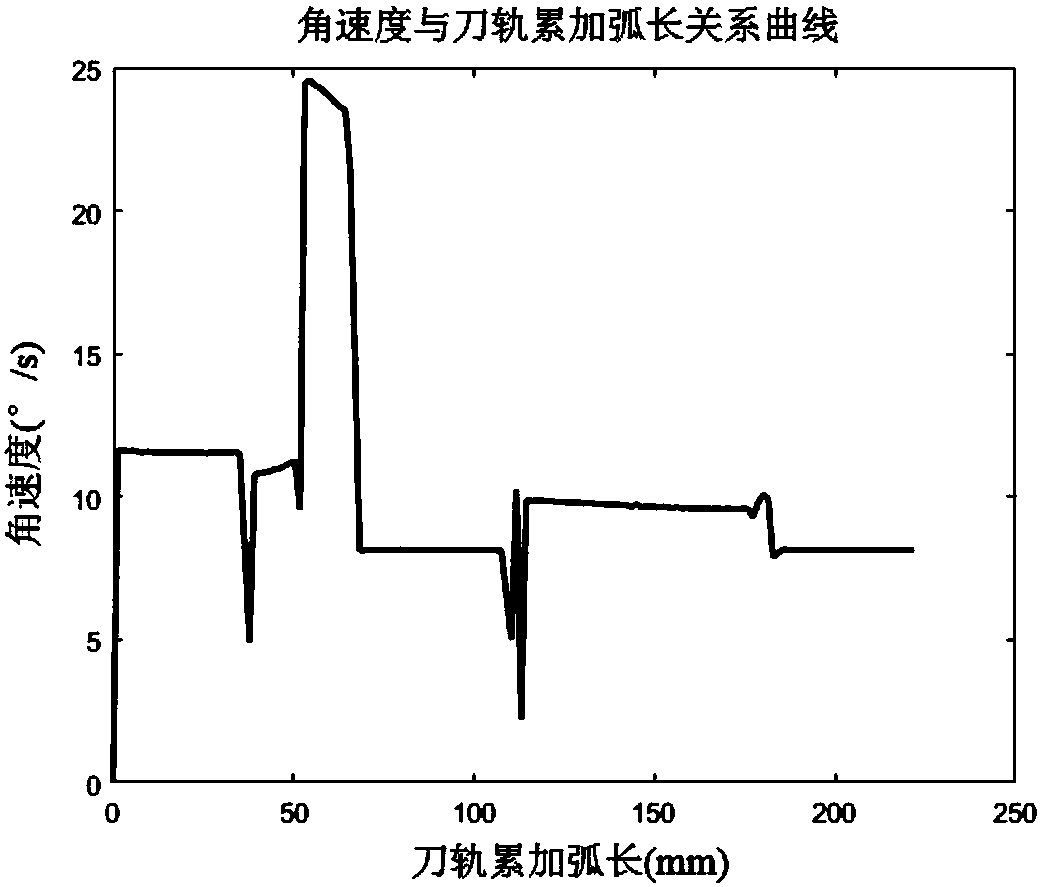

The invention belongs to the technical field of complex surface part high-precision and high-efficiency milling, and relates a tool axis vector fairing method based on the kinematics characteristics of a swivel feeding shaft of a machine tool. The method comprises the steps: taking equal residual height as a constraint to generate a processing tool path according to the geometric features of a curved surface; building a coordinate conversion relation between a workpiece coordinate system and a machine tool coordinate system, converting a tool axis sequence corresponding to a tool contact pointinto a corner sequence of the swivel feeding shaft of the machine tool, and determining a to-be-optimized section according to the angle changes of the swivel feeding shaft of the machine tool; calculating tool axis vector coordinates corresponding to the tool contact point in the to-be-optimized section based on a quaternion method, carrying out the fairing of a corner curve of the swivel feeding shaft of the machine tool through the least square fitting method, and carrying out the interference checking and adjustment of the optimized cut axis vector. The method effectively reduces the motion abrupt changes of the swivel feeding shaft of the machine tool in a machining process, achieves the steady machining, and improves the surface machining quality.

Description

technical field The invention belongs to the technical field of high-precision and high-efficiency milling of complex curved surface parts, and relates to a tool axis vector smoothing method based on the kinematics characteristics of a rotary feed axis of a machine tool. Background technique Complex curved surface parts are widely used in various fields such as aerospace, automobiles, and ships. How to realize high-quality and efficient processing of complex curved surface parts is a hot and difficult point of current research. Compared with three-axis CNC machining, five-axis CNC machining adds two rotation axes. The contact state between the tool and the machined surface can be controlled by adjusting the included angle of the tool relative to the local coordinate system to ensure the processing quality and efficiency of the part, and at the same time avoid the gap between the tool and the workpiece. local and global interference. At present, the direction of the tool axi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G05B19/4097

CPCG05B19/4097G05B2219/35215

Inventor 马建伟胡国庆贾振元苏伟伟秦逢泽

Owner DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com