Electrostatic spray gun water-based paint heating equipment

A technology for electrostatic spray guns and heating equipment, applied in electrostatic heating/cooling devices, liquid spraying equipment, electrostatic spraying devices, etc., can solve problems affecting product quality and poor spraying effect, and achieve good heat preservation effect, good effect, The effect of saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

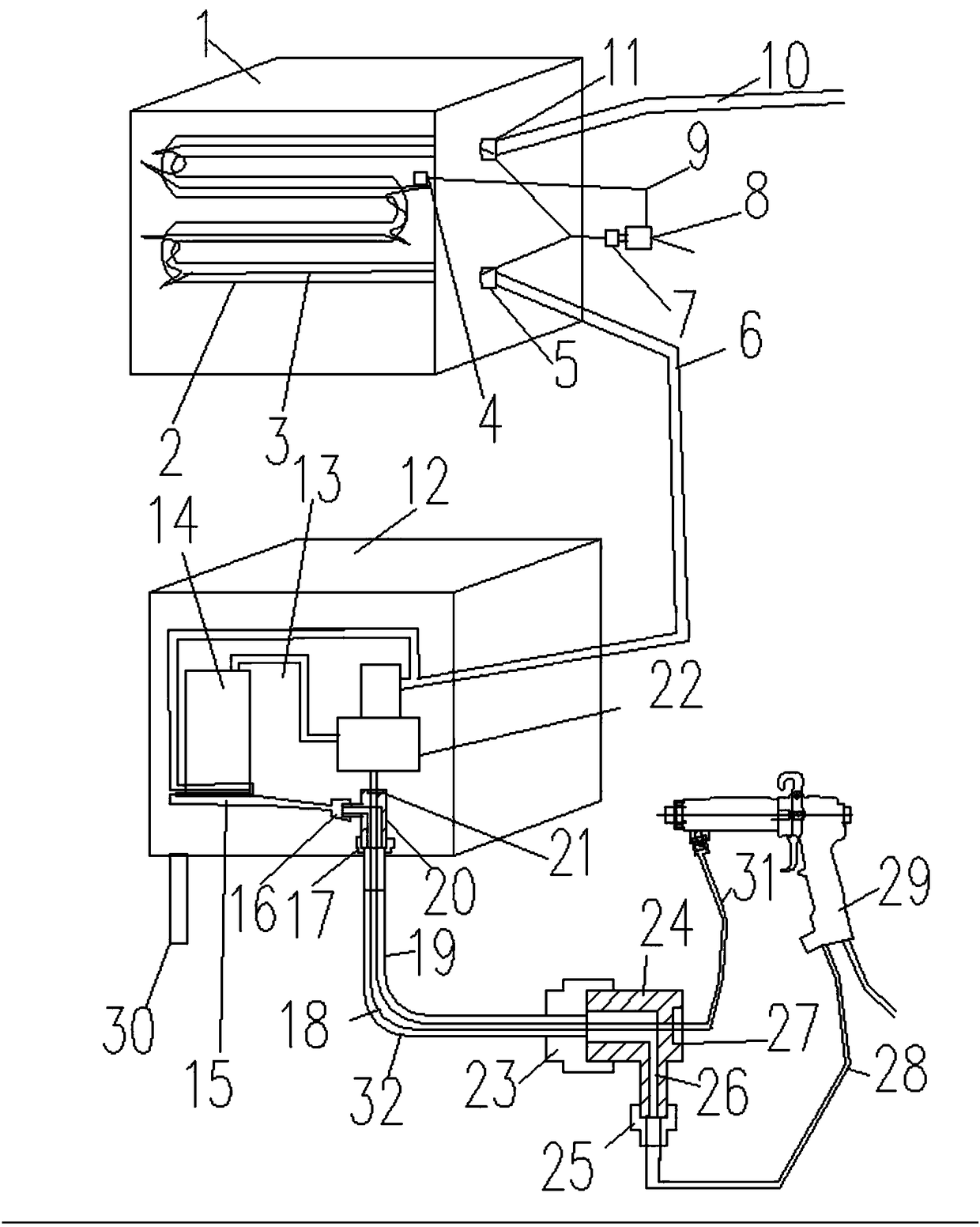

[0030] Such as figure 1 As shown, an electrostatic spray gun water-based paint heating equipment includes an electric heating box 1, an air heating coil 2 is provided in the electric heating box 1, and an electric heating wire 3 is provided in the air heating coil 2 on the electric heating box 1. An inlet connector 11 and an outlet connector 5 are provided. The inlet connector 11 is connected to an air compressor through an air inlet pipe 10, the outlet connector 5 is connected to an outlet hot air pipe 6, and the electric heating box 1 is provided with a thermometer 4, The thermometer 4 is connected to the thermostat 8 through a wire 9. The electric heating box 1 is connected to the socket 7 through a wire, and the socket 7 is connected to the thermostat 8 to connect to electricity. The electric heating box 1 is connected to the isolation box 12 through a pipe. In connection, the isolation box 12 is connected to the electrostatic spray gun 29 through a double-layer pipe 32, the...

Embodiment 2

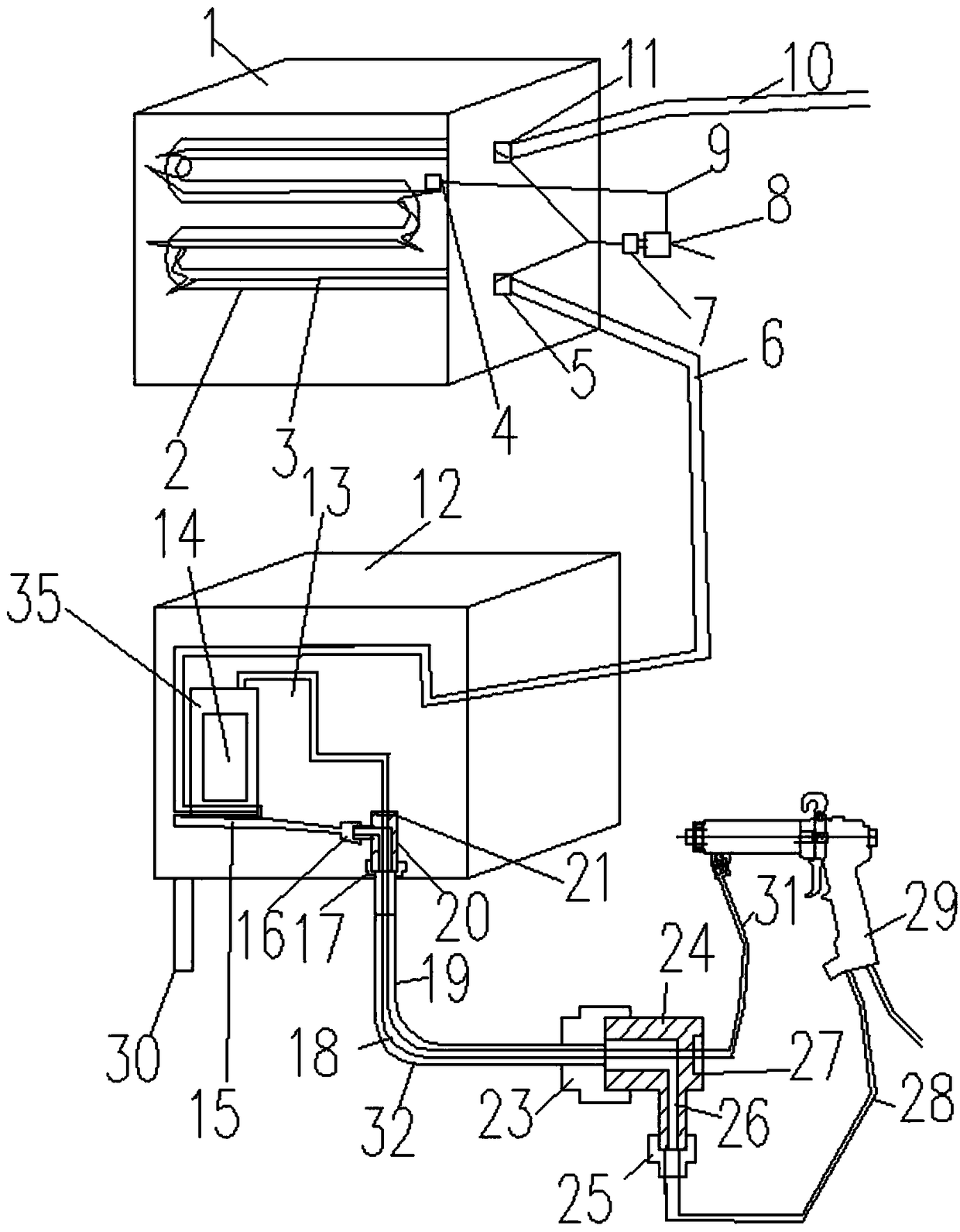

[0033] Such as figure 2 As shown, it is improved on the basis of the first embodiment. The isolation box 12 is provided with a water-based paint storage barrel 14 and a pressure barrel 35. The water-based paint storage barrel 14 is placed in the pressure barrel 35, and the outlet hot air pipe 6 is connected to the heating barrel pipe 15 Heat the pressure tank 35 and the water-based paint storage tank 14, and the upper part of the pressure tank 35 is connected with the double-layer inner pipe 18 through the oil pipe.

Embodiment 3

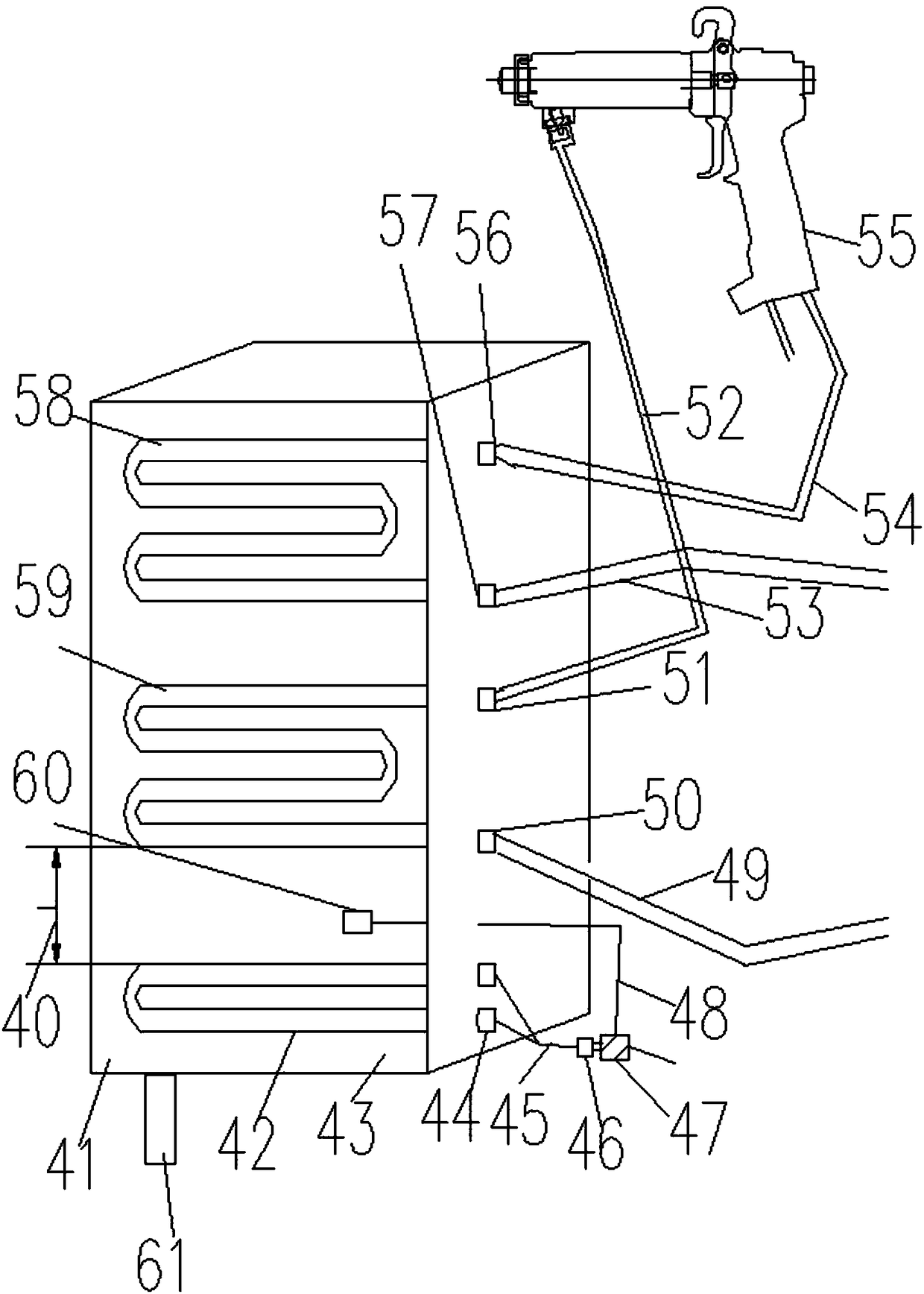

[0035] Such as image 3 As shown, an electrostatic spray gun water-based paint heating equipment, an electric heating box 41 includes an air coil 58, a paint coil 59 and an electric heating coil 42, the air coil 58 is located above the paint coil 59, and the electric heating coil 42 Located at the bottom of the electric heating box 41, there is a distance L40 between the electric heating coil 42 and the paint coil 59. Between the distance L40, a thermometer 60 is provided, and the thermometer 60 is connected to a thermostat 47 through a wire 48 Connected, the electric heating box 41 is filled with insulating oil 43, and the bottom of the electric heating box 41 is provided with an insulating support 61.

[0036] The electric heating coil 42 is provided with a heating pipe joint 44 on the electric heating box 41, the heating pipe joint 44 is connected to the socket 46 through a wire 45, and the socket is connected to the temperature control box 47, and the air coil 58 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com