Magnetic shoe apparent defect detection machine and method for implementing same

A technology of appearance defect detection machine, applied in the field of magnetic tile production, to achieve the effects of high production efficiency, convenient wiring and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

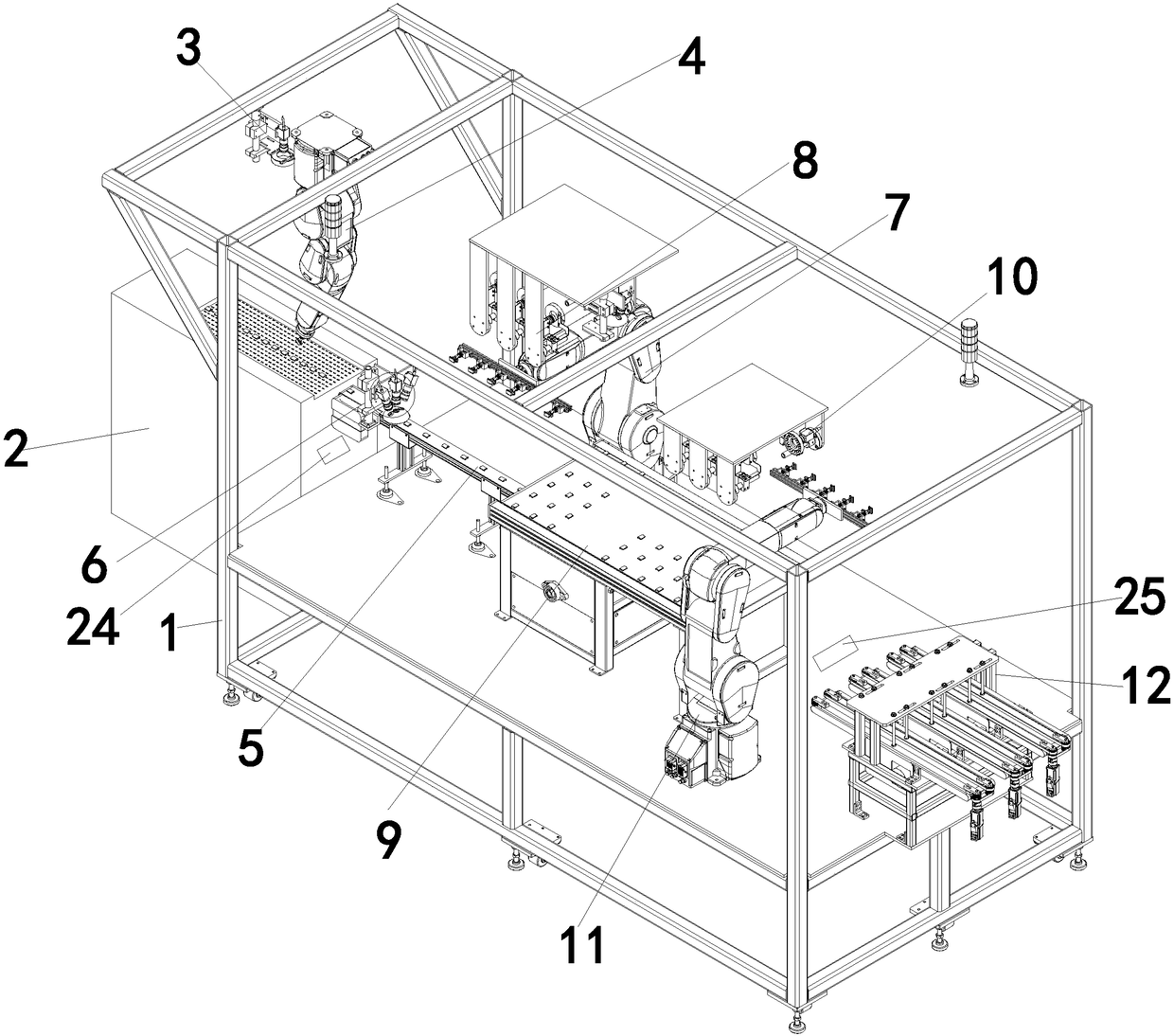

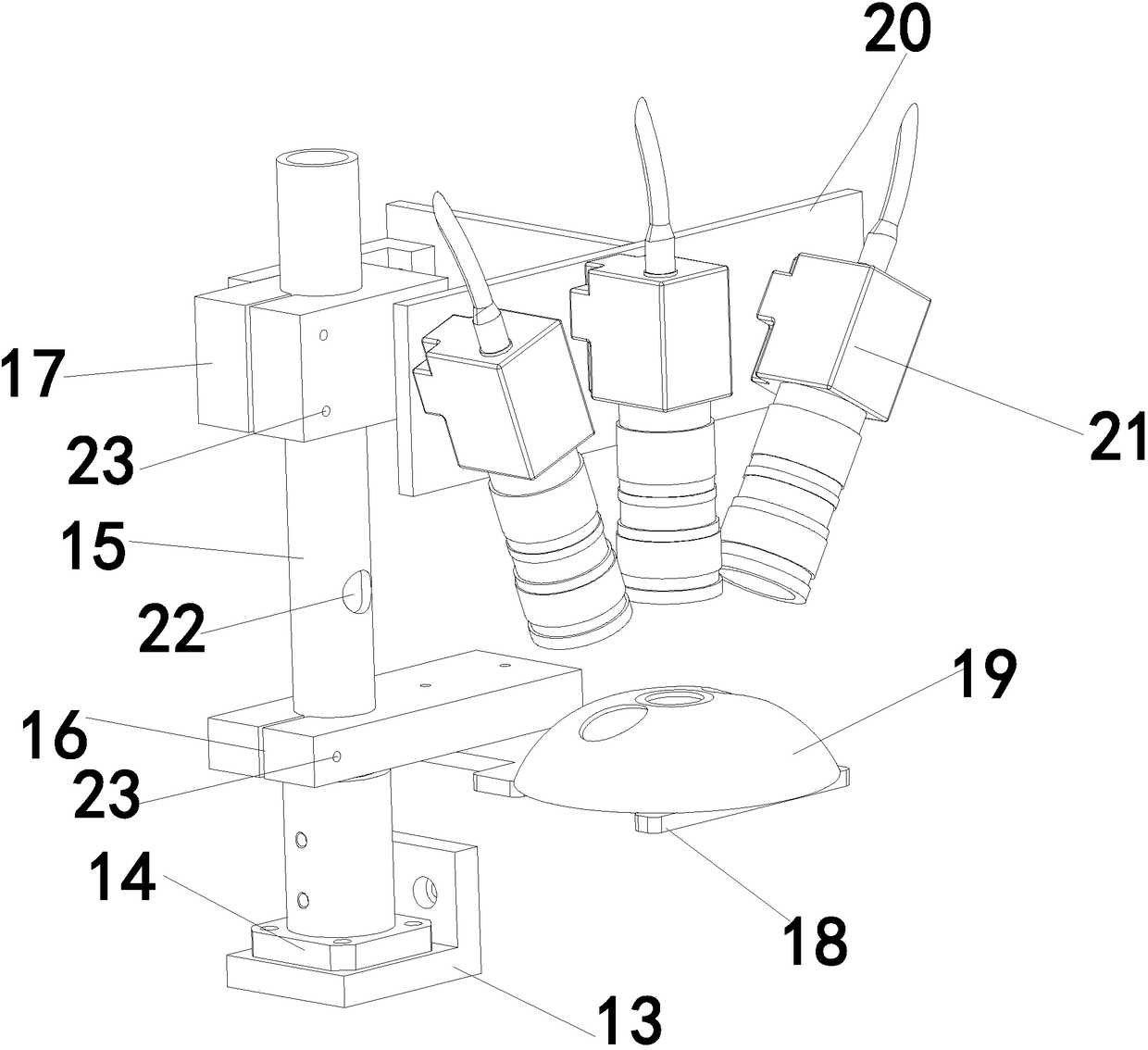

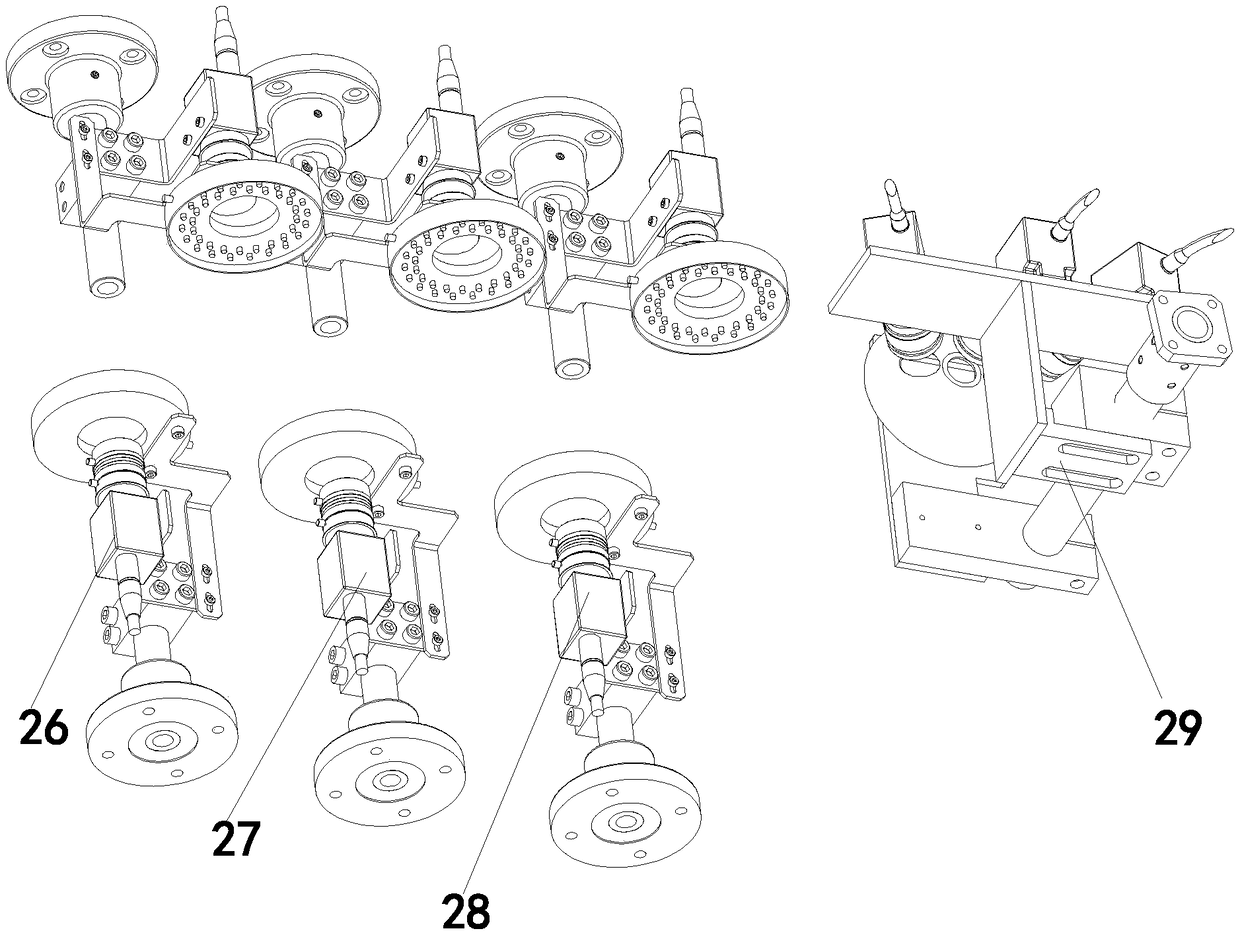

[0038] Such as Figure 1~6 As shown, a magnetic tile appearance defect detection machine includes a frame. The front side of the inlet end of the frame is a cleaning machine. A dynamic recognition camera is arranged above the inlet end of the frame. Set the first belt line at the end, the side of the first belt line is fixedly connected to the outer arc surface detection device, the second robot is set on the side of the first belt line, the first detection unit is set above the first belt line, and the outlet end of the first belt line is set There is a wide belt conveyor line, the frame above the wide belt conveyor line is fixedly connected with the second detection unit, the side of the wide belt conveyor line is equipped with a third robot, and the outlet end of the wide belt conveyor line is equipped with a discharge device; the controllers are respectively It is signal-connected with the dynamic recognition camera, the first robot, the outer arc detection device, the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com