Fixing device for steel pipe welding

A technology for fixing devices and steel pipes, applied in auxiliary devices, welding equipment, welding equipment, etc., can solve problems such as troublesome and laborious welding butt joints, uneven welding of steel pipes, and insufficient use effects, etc., to achieve flexible and convenient welding work , good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

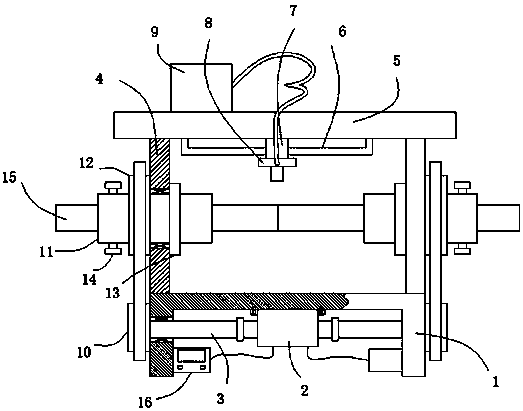

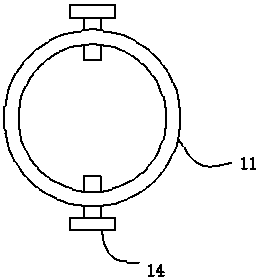

[0017] refer to Figure 1-2 , a fixing device for steel pipe welding, comprising a mounting seat 1 with a mounting groove at the bottom, a group of mounting plates 4 are vertically welded on the top of the mounting seat 1, and a fixing plate 5 is welded on the top of the mounting plate 4, and the top of the fixing plate 5 A gas cylinder 9 is placed, and a U-shaped guide rod 6 is welded on the bottom of the fixed plate 5, and a hollow slider 7 is slidably sleeved on the outer side of the U-shaped guide rod 6, and the bottom of the hollow slider 7 is fixed with a welding body 8 , the mounting seat 1 is screwed with the double-headed motor 2 located inside the installat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap