A kind of manufacturing process of hat metal sign

A production process and metal technology, which is applied in the field of metal sign production technology, and can solve the problems of uneven coating, affecting the appearance, and reducing the appearance quality of metal signs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

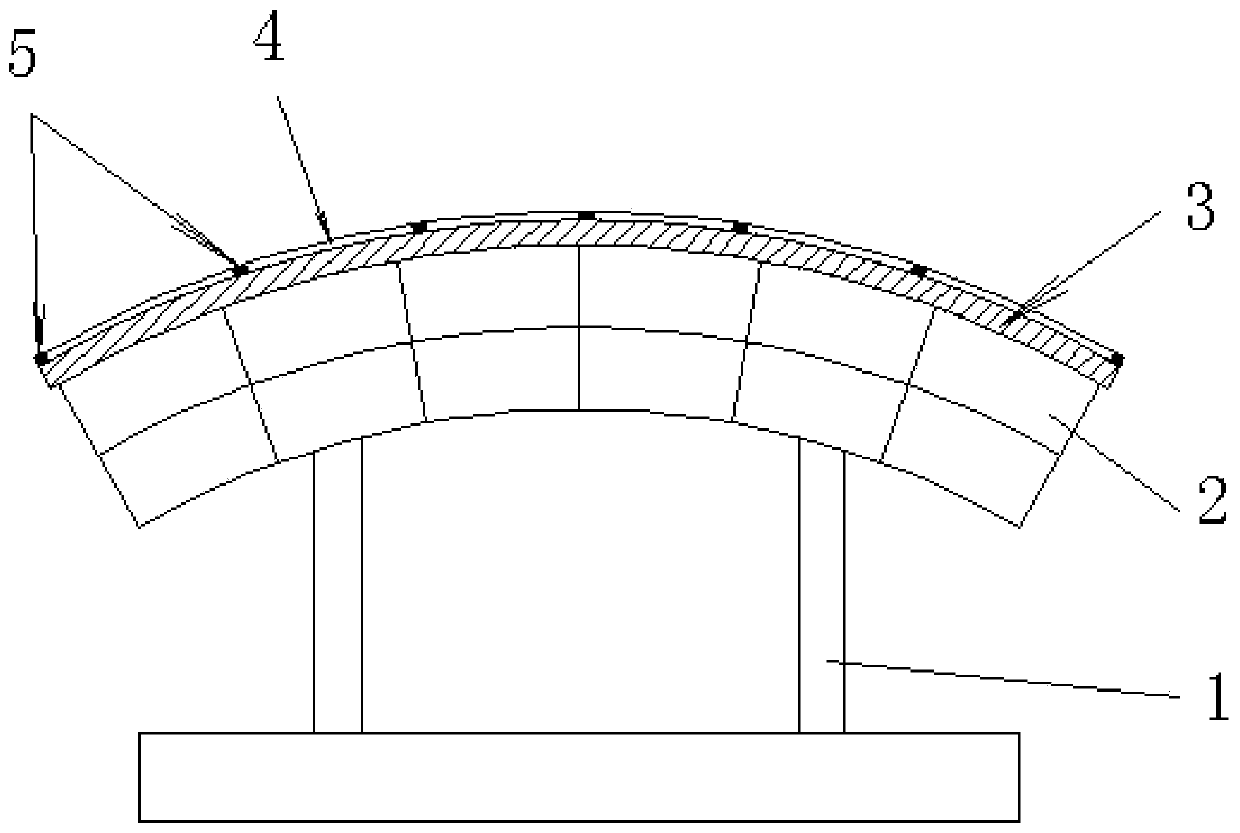

[0033] Such as figure 1 Shown is the embodiment of the manufacturing process of a kind of cap metal signage of the present invention, comprises following processing step:

[0034] Step 1, blanking process: using steel plate as the blank;

[0035] Step 2, punching process: on the punching machine, use a mold to punch out the shape of the metal sign 3;

[0036] Step 3, the process of pre-coating the resist layer: coating the outer surface of the punched metal sign 3 with a layer resist layer; the thickness of the resist layer is equal to the design height of the trace line of the metal sign 3 pattern;

[0037] Step 4. Process of numerically-controlled draw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com