Delivering mechanism of electroplating rack

A technology of electroplating racks and transmission mechanisms, which is applied in the direction of conveyors, conveyor objects, mechanical conveyors, etc., can solve the problems of difficult stability of electroplating racks, large manpower and time consumption of electroplating racks and products to be electroplated, etc. Achieve the effect of saving time and manpower, simple structure and avoiding shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

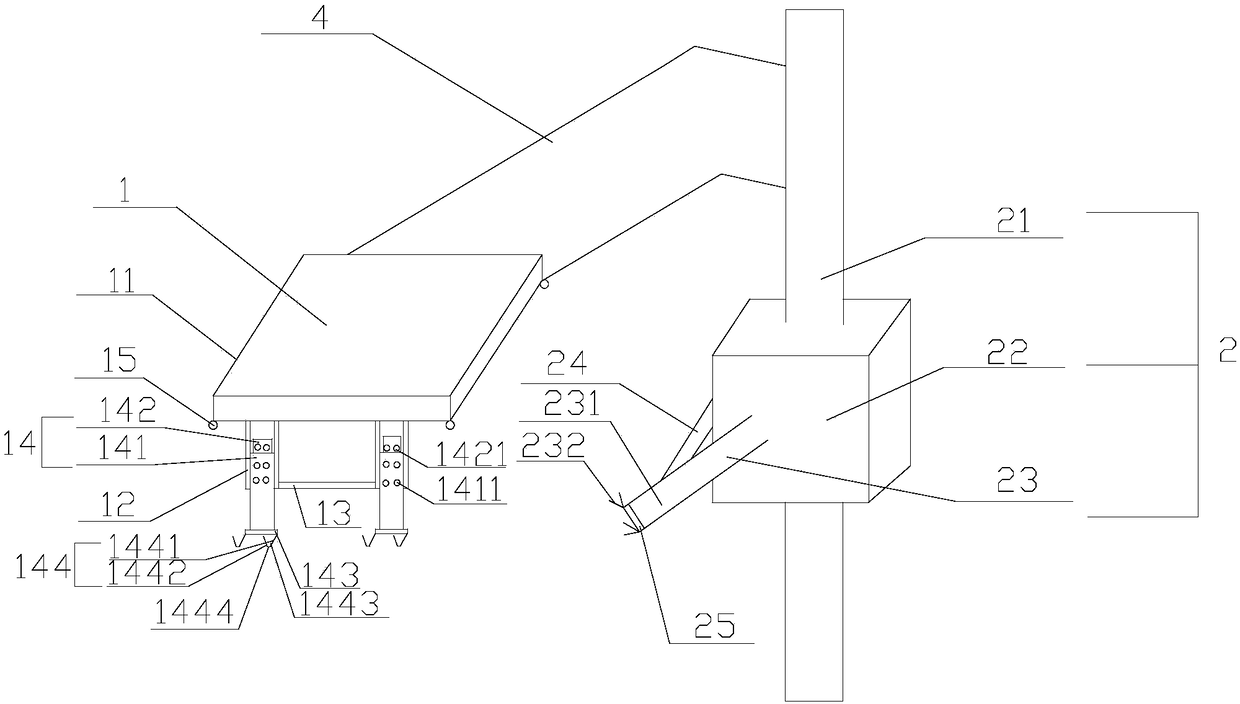

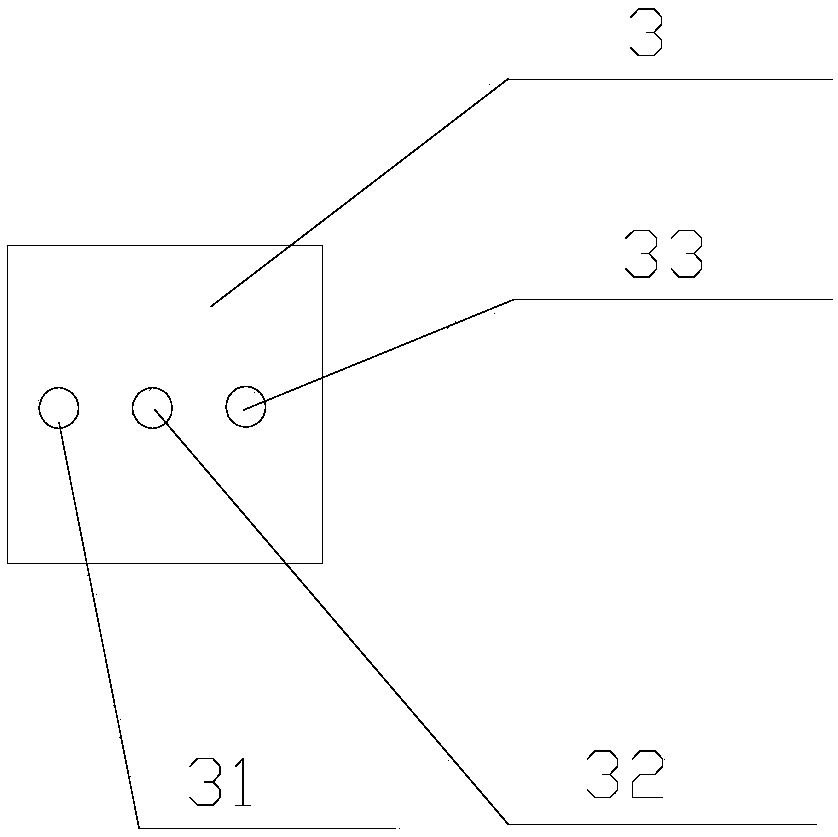

[0017] Please refer to figure 1 and figure 2 , the embodiment of the present invention provides a kind of electroplating hanger conveying mechanism, comprises the horizontal conveying device 1, the vertical conveying device 2 and the power control device 3 that are provided independently, and the horizontal conveying device 1 is positioned at the front of the vertical conveying device 2, and Set on the horizontal guide rail 4 controlled by the motor, the horizontal transmission device 1 includes a fixed seat 11, two vertical guide rails 12 are connected under the fixed seat 11, the upper end of the vertical guide rail 12 is fixedly connected with the fixed seat 11 by bolts, and the two vertical guide rails 12 They are connected by a horizontal support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com