A magneto-rheological active sound-absorbing muffler for automobile engine exhaust system

A technology for automobile engines and exhaust systems, which is applied in the direction of engine components, combustion engines, machines/engines, etc. It can solve the problems of narrow absorption frequency band, automatic adjustment of exhaust muffler muffler frequency, and unsatisfactory exhaust muffler effect, etc., to achieve reduction Effects of regenerative noise and absorption bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

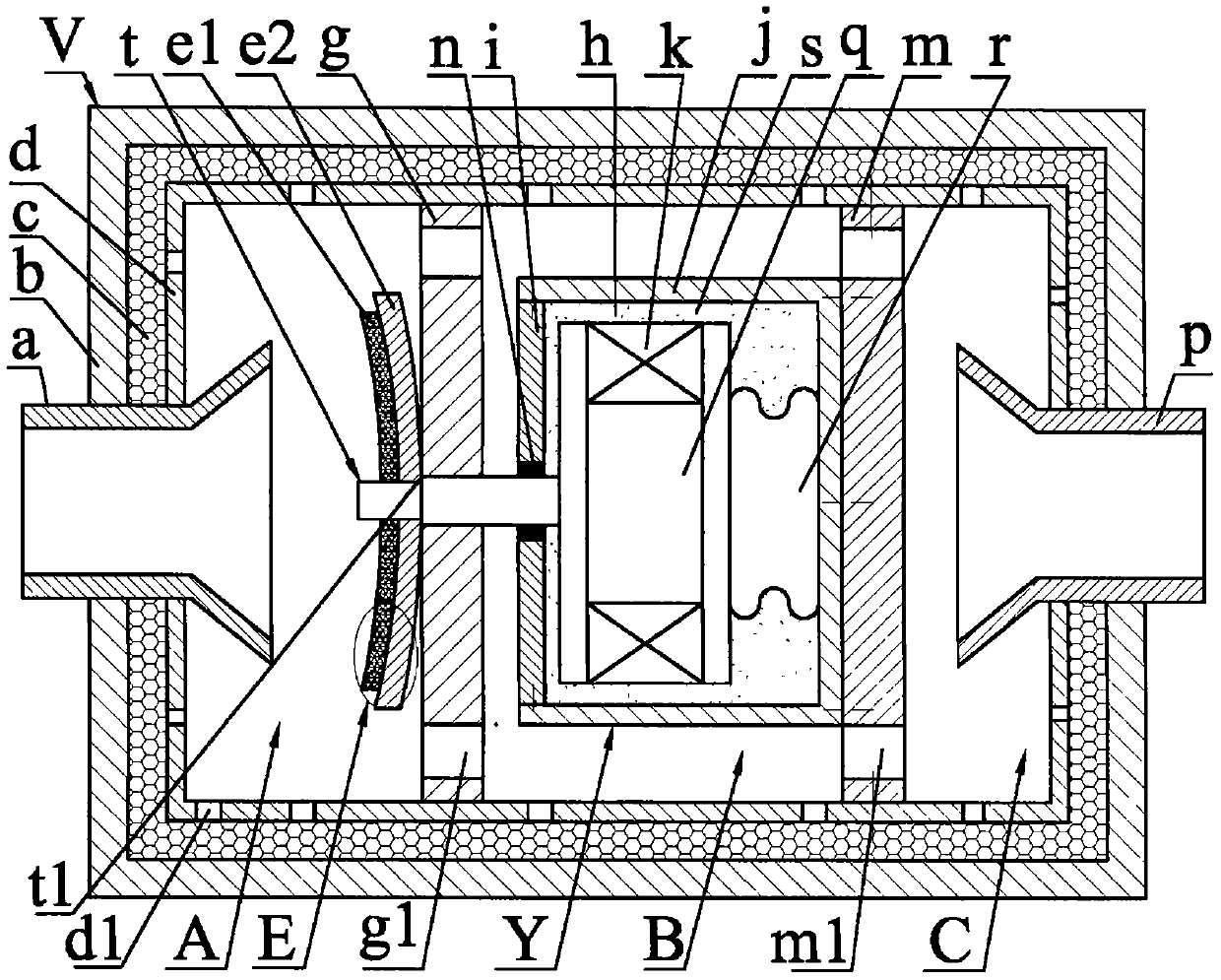

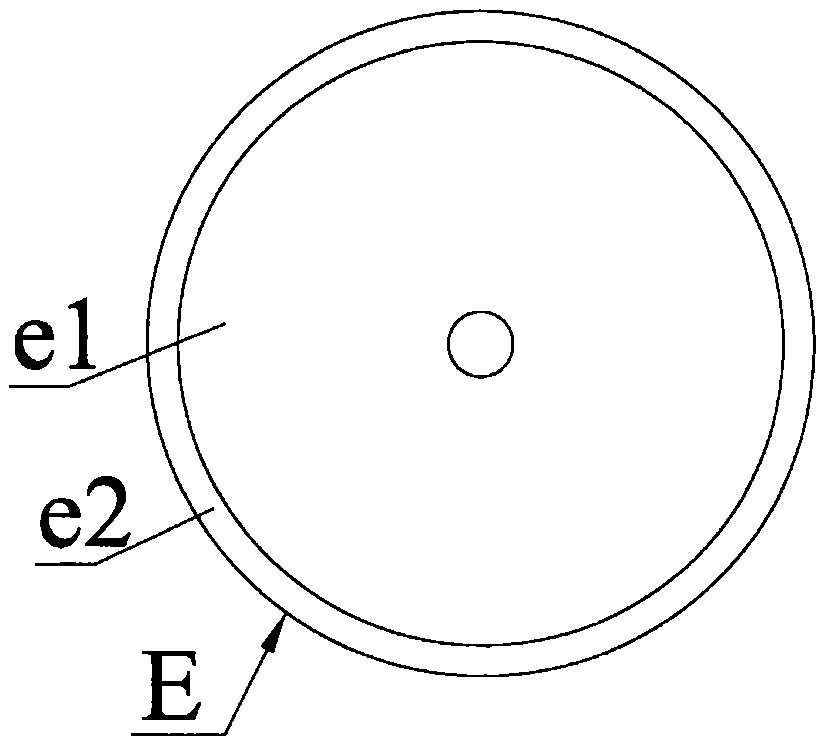

[0011] A magneto-rheological active sound-absorbing muffler for an automobile engine exhaust system, comprising a hollow cylindrical cylinder V, and an inlet pipe a and an air outlet pipe p are respectively arranged at both ends of the axis of the cylinder V; the cylinder V includes a shell Body b, glass wool c, and perforated plate d, with a number of air holes d1 on the perforated plate d; inside the cylinder V, the cylinder V is divided into the first chamber by the left piston g and the partition m along the direction perpendicular to the axis of the cylinder V A, the second chamber B and the third chamber C, the air inlet pipe a communicates with the first chamber A, the air outlet pipe p communicates with the third chamber C, the air outlet of the air inlet pipe a and the air inlet of the air outlet pipe p Bell-mouth shape is adopted; left flow holes g1 and right flow holes m1 are evenly distributed on the left piston g and the partition m, the left piston g can move left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com