Square exhaust sound-muffling box for vehicle

A sound-absorbing box, square technology, applied in the direction of sound-absorbing devices, exhaust devices, engine components, etc., can solve the problems of unsatisfactory sound-absorbing effect of high-frequency noise, no resistive sound-absorbing materials, etc., to achieve good sound-absorbing effect, good effect effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

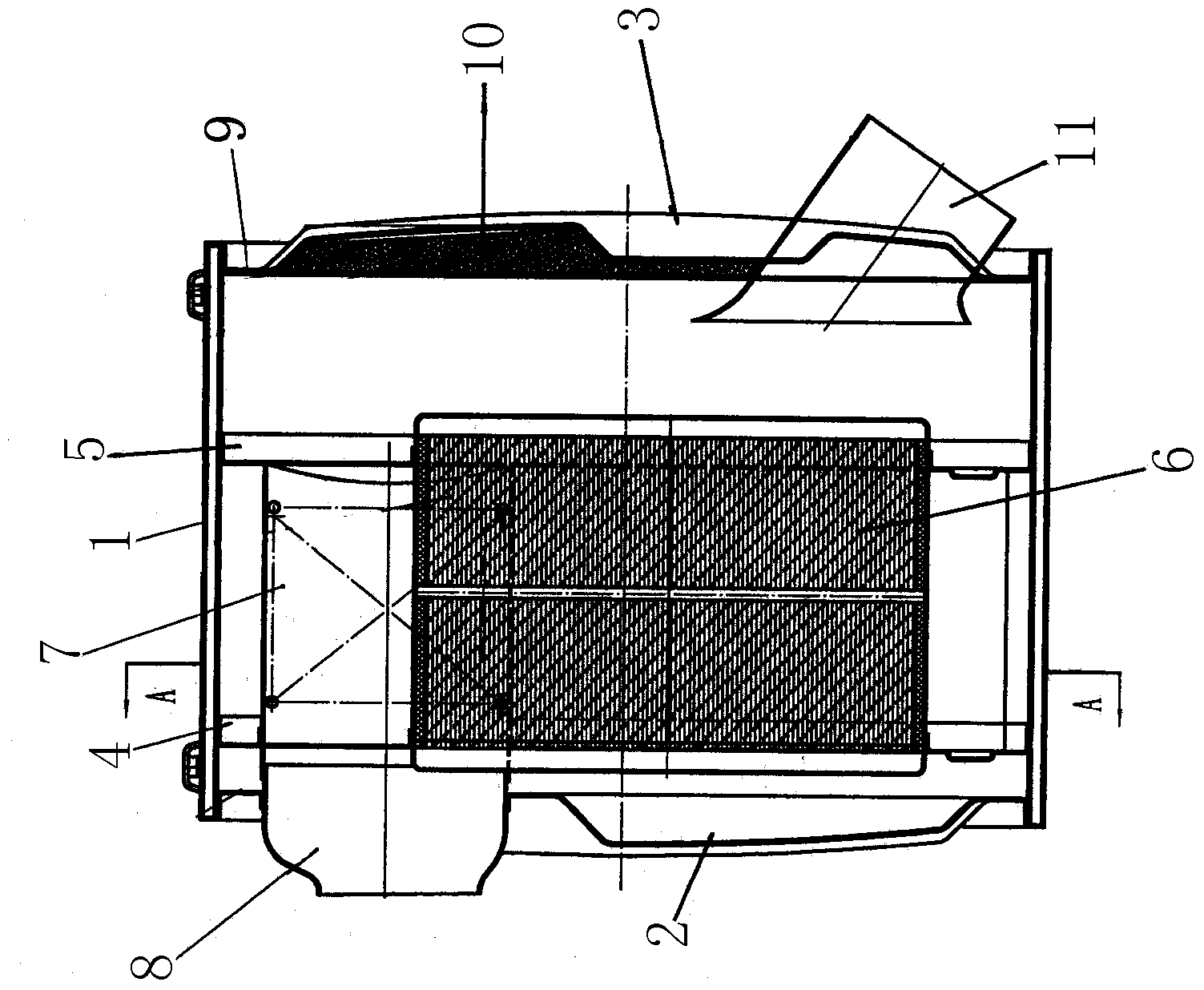

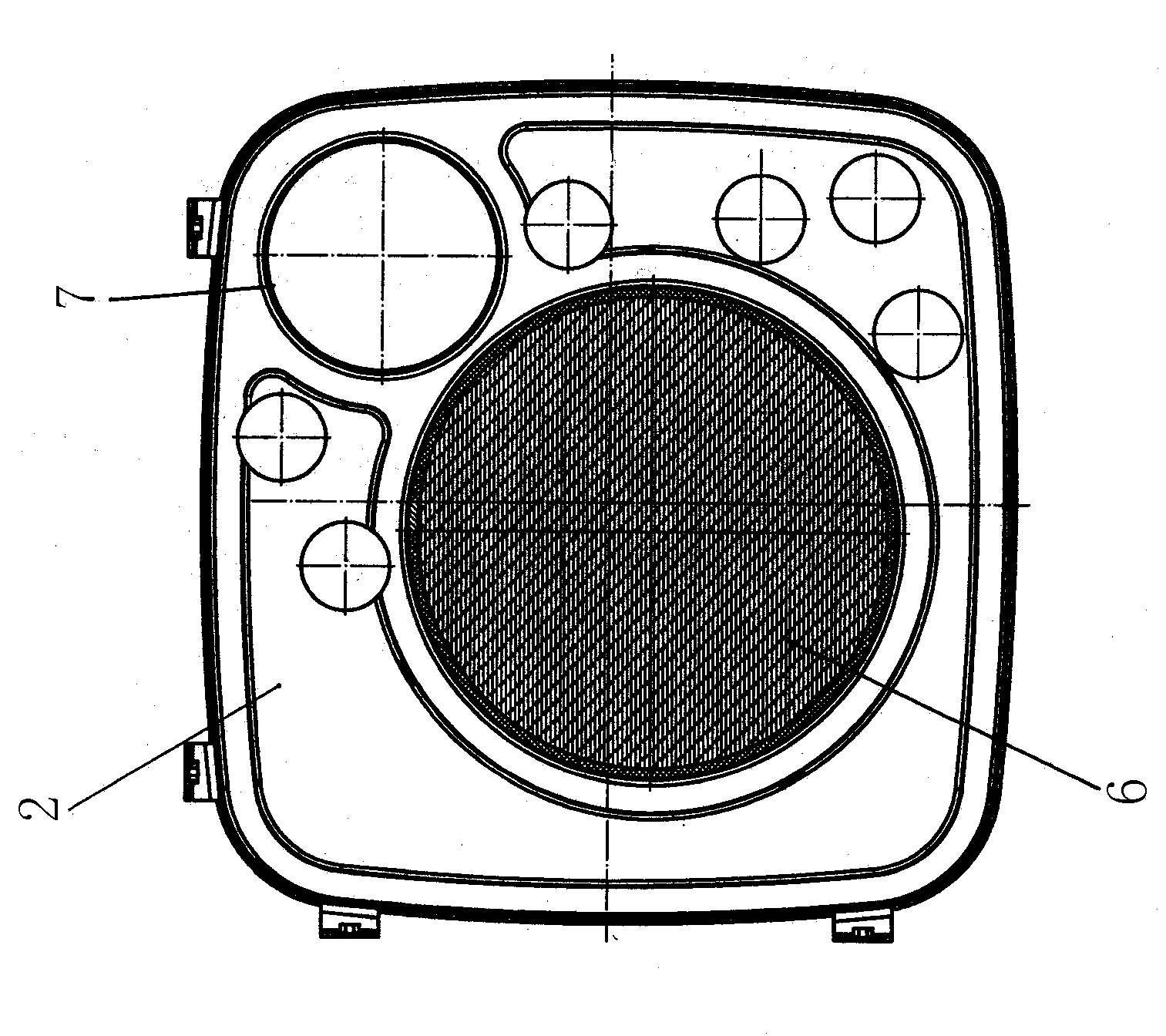

[0010] like figure 1 , 2 As shown, the present invention is respectively welded with front end cover 2 and rear end cover 3 at the two ends of square housing 1, and front bulkhead 4 and rear bulkhead 5 space the interior of square shell 1, between front bulkhead 4 and rear bulkhead. The middle part between the partitions 5 supports a catalytic converter 6, the air intake expansion pipe 7 is arranged on the upper side between the front partition 4 and the rear partition 5, and the intake bowl 8 is arranged on the upper part of the front end cover 2. side, the intake bowl 8 is connected to one end of the intake expansion tube 7, the other end of the intake expansion tube 7 is closed by the rear partition 5, and the mesh plate 9 is arranged on the inner side of the rear end cover 3. Glass fiber 10 is filled between the net plate 9 and the rear end cover 3 , and the air outlet pipe 11 is arranged at the bottom of the rear end cover 3 . Through the above settings, from the noise ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com