An exhaust muffler suitable for exhaust heat and electricity recovery

An exhaust muffler and thermoelectric technology, which is applied in the direction of exhaust devices, gas chambers, and mufflers, can solve the problem of the installation position contradiction between the heat collection box and the exhaust muffler, achieve compact structure, reduce back pressure and noise , The effect of thermoelectric power generation exhaust noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

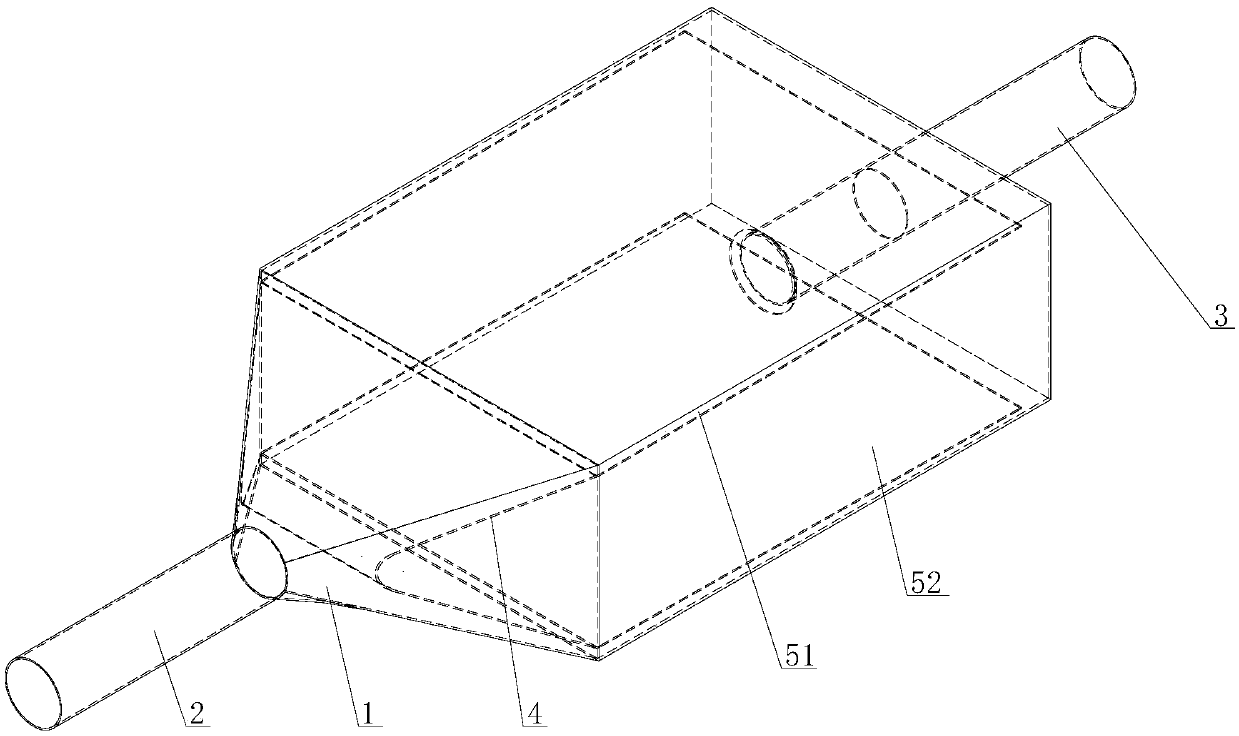

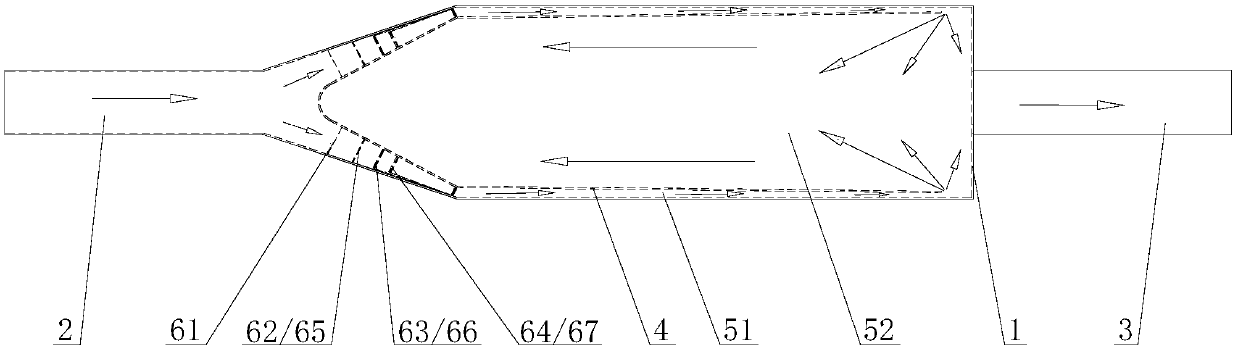

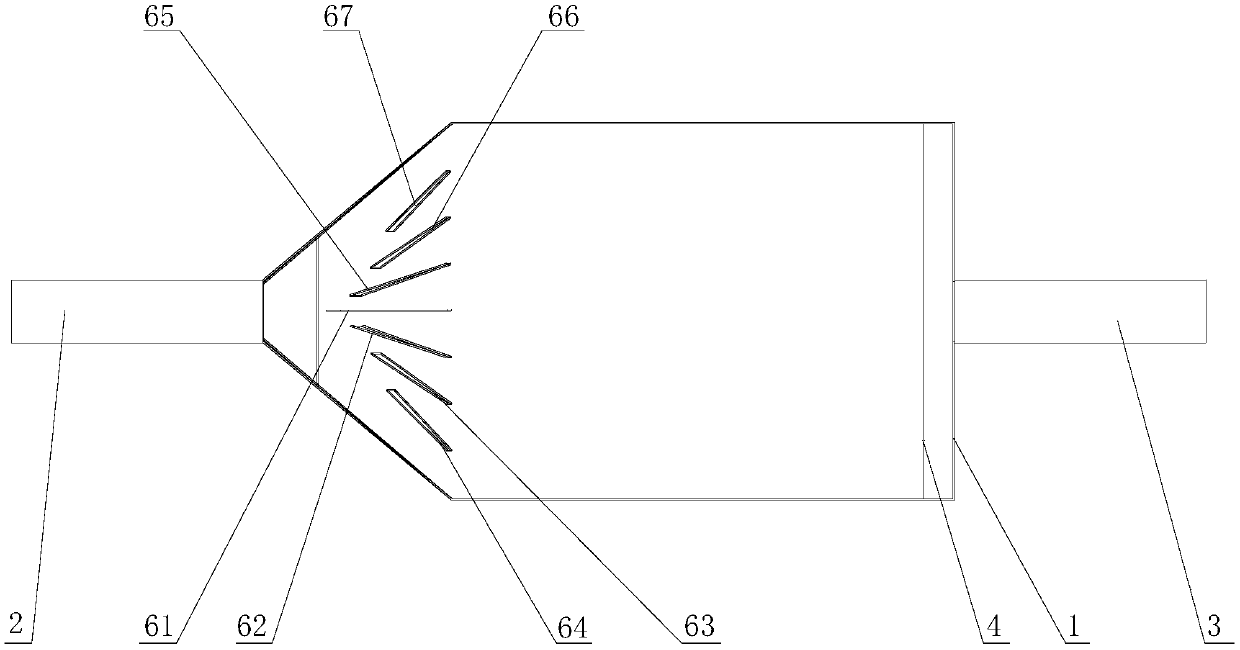

[0022] see Figure 1~Figure 3 The shown exhaust muffler suitable for exhaust heat and electricity recovery includes a housing 1, the housing 1 has an air inlet and an exhaust port, and the exhaust muffler also includes an air inlet pipe 2 connected to the air inlet, connected to The exhaust pipe 3 at the position of the exhaust port, the airflow flows into the housing 1 from the intake pipe 2 and flows out of the housing 1 from the exhaust pipe 3 .

[0023] One end of the housing 1 gradually narrows from the inside to the outer edge, and the air inlet is located at the smallest end of the housing 1 . A specific embodiment, the housing 1 is in the shape of a cuboid with a constriction at one end, the length extension direction of the housing 1 is the same as the flow direction of the air flow, and the air inlet is loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com