Distributed direct drive excavator hydraulic system with servo motor-driven double variable pumps

A servo motor and hydraulic system technology, applied in the hydraulic field, can solve the problems of inability to recover negative loads and high motor performance requirements, and achieve the effects of less pressure loss, less heat generation, and high system efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

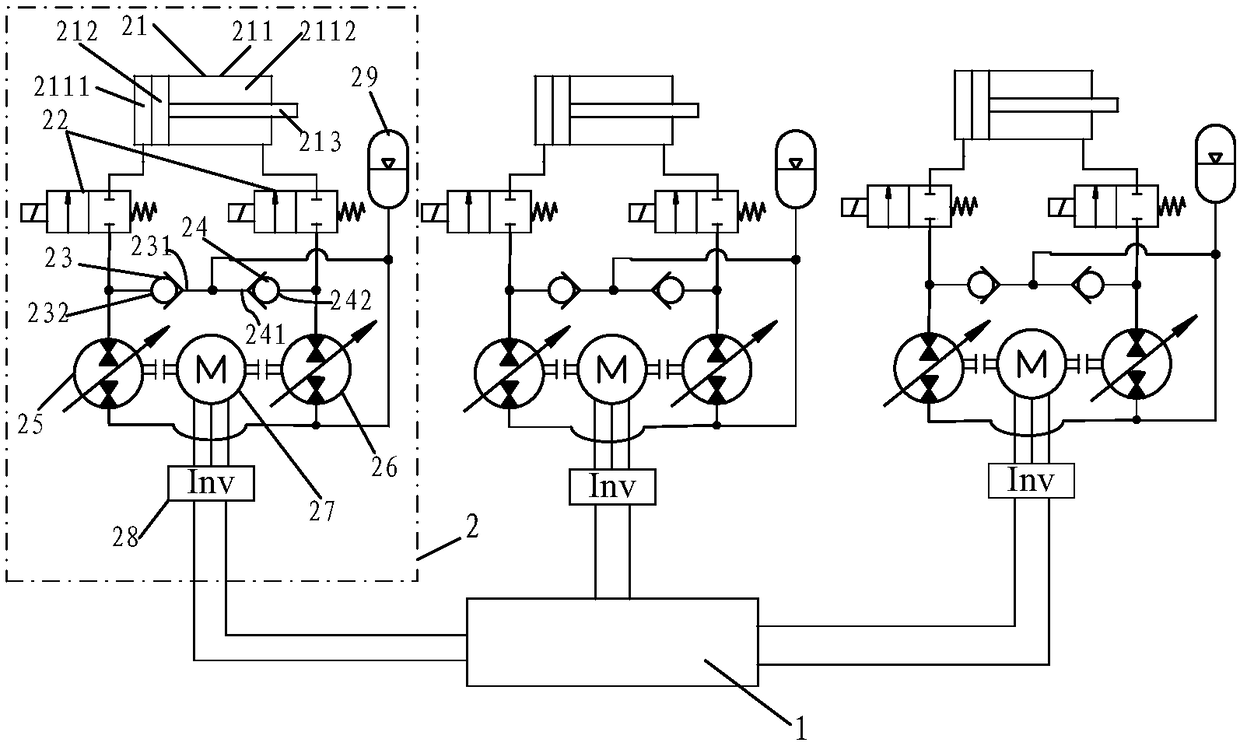

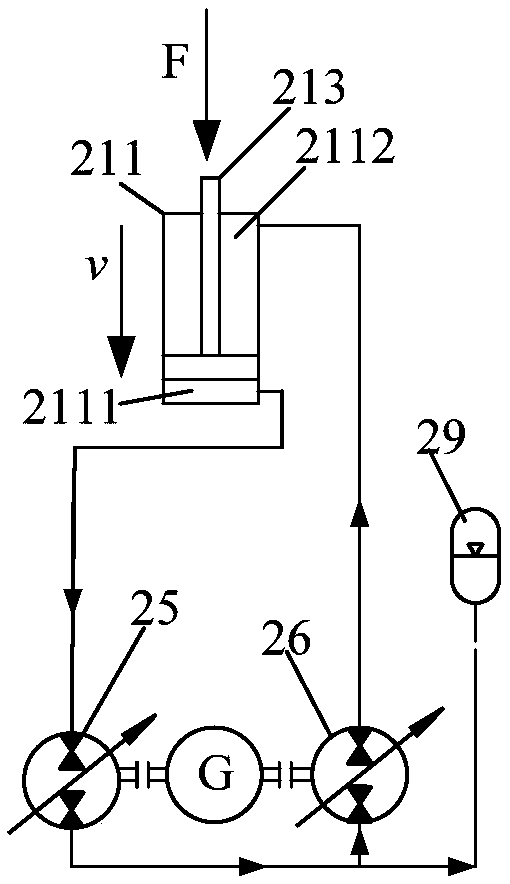

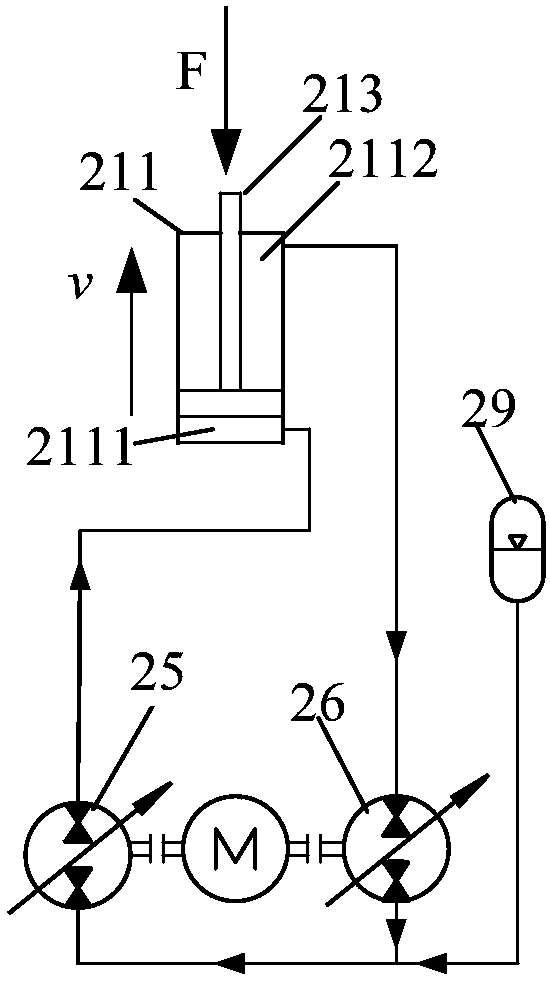

[0022] see figure 1 As shown, the present invention provides a distributed direct-drive excavator hydraulic system with a servo motor driving a dual-variable pump, including a controller 1, a power supply unit (not shown) and at least one hydraulic module 2; the hydraulic module 2 Including a hydraulic cylinder 21, a first two-way variable pump 25, a second two-way variable pump 26, a servo motor 27, a frequency converter 28 and an accumulator 29; the hydraulic cylinder 21 includes a cylinder body 211, a piston 212 and a piston rod 213, one end of the piston rod 213 is fixedly connected to the piston 212, the piston 212 is airtightly and slidably connected in the cylinder body 211, and the piston 212 connects the cylinder body 211 The interior is divided into a first chamber 2111 and a second chamber 2112;

[0023] The frequency converter 28 and the controller 1 are respectively electrically connected to the power supply device (not shown), the frequency converter 28 is elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com